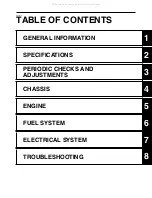

Summary of Contents for XT250X 2008

Page 2: ...All manuals and user guides at all guides com...

Page 8: ...All manuals and user guides at all guides com...

Page 54: ...CABLE ROUTING 2 35 All manuals and user guides at all guides com...

Page 82: ...ELECTRICAL SYSTEM 3 27 a b All manuals and user guides at all guides com...

Page 170: ...VALVES AND VALVE SPRINGS 5 24 All manuals and user guides at all guides com...

Page 224: ...AIR INDUCTION SYSTEM 6 13 All manuals and user guides at all guides com...

Page 239: ...CHARGING SYSTEM 7 14 All manuals and user guides at all guides com...

Page 243: ...LIGHTING SYSTEM 7 18 All manuals and user guides at all guides com...

Page 249: ...SIGNALING SYSTEM 7 24 All manuals and user guides at all guides com...

Page 253: ...CARBURETOR HEATING SYSTEM 7 28 All manuals and user guides at all guides com...

Page 279: ...All manuals and user guides at all guides com...