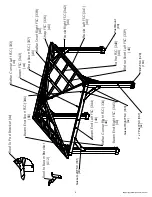

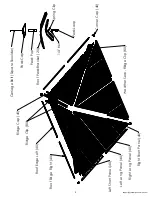

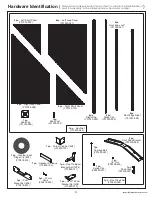

3.6m x 3.6m (12’ x 12’) WOOD GAZEBO

with ALUMINUM ROOF

Installation and Operating Instructions – YM12810X

Revised 07-31-2020

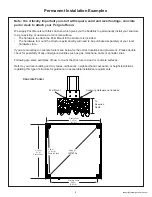

12'-1 5/32"

3687.1

12'-1 5/32"

3687.1

HEIGHT:

3.2m (10.5’)

Y40000-810X

IMPORTANT, RETAIN FOR FUTURE REFERENCE: READ CAREFULLY

Yardistry – North America

Toll Free Customer Support:

1.888.509.4382

info@yardistrystructures.com

www.yardistrystructures.com

Regular Hours: Mon - Fri, 8:30 am - 5:00

pm EST (excl. holidays)

(For extended hours see our website)

English and French Spoken

(12’ 1-5/32”)

(12’ 1-5/32”)

3.687 m

3.687 m