GENERAL

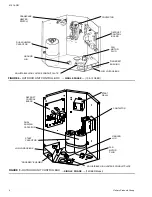

These outdoor heat pump units are designed to be connected

to a matching UPG indoor coil with sweat connection lines. They

are equipped with a solid core filter-drier located in the dis-

charge line, a high pressure switch, a high temperature switch

(14 SEER models only). The units are factory charged with

refrigerant for a matching indoor coil plus 15 feet of field

supplied line. The outdoor unit is designed to be placed along-

side or at the back of the home, remote from the indoor coil.

The outdoor unit has been factory run-tested and all compo-

nents of the system are ready for easy, immediate installation.

INSPECTION

Check the unit thoroughly for shipping damage. Unusually

rough handling during shipment may loosen fan motors, com-

pressors, or other components. Be sure that the unit is ready

to operate before installing it. If there is damage, file a claim

with the shipper. See Local Distributor for more information.

REFERENCE

Use this instruction in conjunction with the instructions for the

appropriate indoor unit, air moving system and accessories.

Installer should pay particular attention to the words NOTE,

CAUTION and WARNING.

NOTES are intended to clarify or make the installation easier.

CAUTIONS identify procedures which, if not followed carefully,

could result in personal injury, property damage or product

damage.

WARNINGS are given to alert the installer that severe personal

injury, death or equipment damage may result if installation

procedures are not followed properly.

NOMENCLATURE

LIMITATIONS

CAUTION: The manufacturer is not responsible for the

performance of a mismatched system. The out-

door unit must be installed with a compatible

indoor unit as designated in the specification

data or in the Directory of Certified Unitary Heat

Pumps published by the Air Conditioning and

Refrigeration Institute. Using unmatched com-

ponents may not only affect the performance of

the system, but may also void the warranty of

the equipment.

Do not install any coil in a furnace which is to

be operated during the heating season without

attaching the refrigerant lines to the coil. Allow-

ing the coil charge to enter the refrigerant lines

prevents excessive refrigerant pressure build-

up and possible coil damage.

The unit should be installed in accordance with all national and

local codes and regulations which govern the installation of this

type of equipment. In lieu of local codes, the equipment should

be installed in accordance with the National Electric Code, and

in accordance with the recommendations made by the National

Board of Fire Underwriters.

Limitations for the indoor unit, coil and appropriate accessories

must also be observed.

The outdoor unit must not be installed with any duct work in the air

stream. The outdoor fan is the propeller type and is not designed

to operate against any additional external static pressure.

The maximum and minimum conditions for operation must be

observed to assure a system that will give maximum perform-

ance with minimum service.

042 = 42,000 Btuh

048 = 48,000 Btuh

060 = 60,000 Btuh

INSTALLATION INSTRUCTION

Supersedes: 515.16-N3Y Coded 1097

515.16-N3Y (298)

OUTDOOR

SPLIT-SYSTEM HEAT PUMPS

1.5 TO 5 TONS

®

MODELS E*RA (1 & 3 Ø), E*RC and E*RE

10, 12, 14 SEER

035-15754

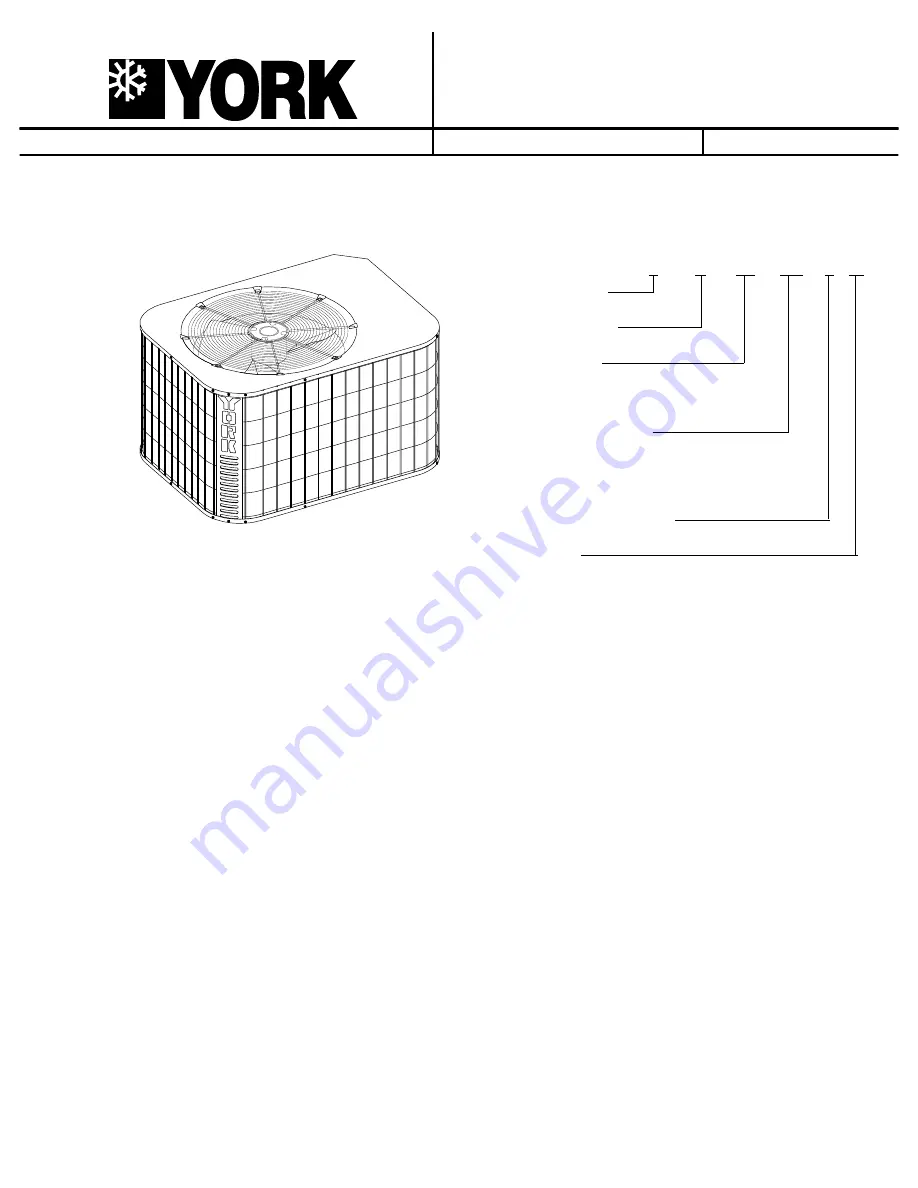

E 1 RA 036 S 06

Product Category

E = Heat Pump, Outdoor Unit

1 = 1st Generation

Product Generation

Product Identifier

RA = 10 SEER Split System Heat Pump

RC = 12 SEER Split System Heat Pump

RE = 14 SEER Split System Heat Pump

Nominal Cooling Capacity

018 = 18,000 Btuh

024 = 24,000 Btuh

030 = 30,000 Btuh

036 = 36,000 Btuh

Refrigerant Line Connections

S = Sweat Connect

Voltage Code

06 = 208/230-1-60

25 = 208/230-3-60

46 = 460-3-60