PAGE 1

I

-

Shipping And Packing List

Package 1 of 2 contains:

1 - Energy Recovery Ventilator Assembly

1 - Outdoor Fresh Air Hood w/ Filter

1 - Outdoor Exhaust Hood w/ Barometric Dampers

1 - Bag Assembly

1 - Roll of ¾" x 1 ¼" gasket

1 - 272" of

1

8

" x ½" gasket

1 - Field Wiring Harness

1 - Adapter Wiring Harness

10 - #14 Screws

10 - #10 x 1 ½" Screws

30 - #10 x ½" Gold Screws

1 - Installation Instructions

Package 2 of 2 contains:

1 - Balancing Damper Assembly

1 - Platform Support Plate

2 - Side Filler Panel

2 - Door Panels

II -

Shipping Damage

Check unit for shipping damage. Receiving party should

contact last carrier immediately if shipping damage is

found.

III -

General

These instructions are intended as a general guide and do

not supersede local codes in any way. Authorities having

jurisdiction should be consulted before installation.

IV -

Requirements

When installed, the unit must be electrically wired and

grounded in accordance with local codes or, in absence of

local codes, with the current National Electric Code,

ANSI/NFPA No. 70.

V -

Application

Unitary Energy Recovery Ventilator (UERV) are used with

15 to 25 ton units

equipped with a return damper

assembly.

These wheels conserve energy by mixing

warmer air with cooler air in the following manner:

Recovery Wheel Mode

The Recovery Wheel mode is accomplished by two

blowers providing continuous exhaust of stale indoor air

and replacement by equal amount of outdoor air. Energy

recovery is achieved by slowly rotating the energy

recovery wheel within the cassette frame work. In winter,

the UERV absorbs heat and moisture from the exhaust air

stream during one half of a complete rotation and gives

them back to the cold,drier intake air supply during the

other half rotation. In summer, the process is automatically

reversed. Heat and moisture are absorbed from incoming

fresh air supply and transferred to the exhaust air stream.

This process allows outdoor air ventilation rates to be

increased by factors of three or more without additional

energy penalty or increase in size of heating or air

conditioning systems.

VI -

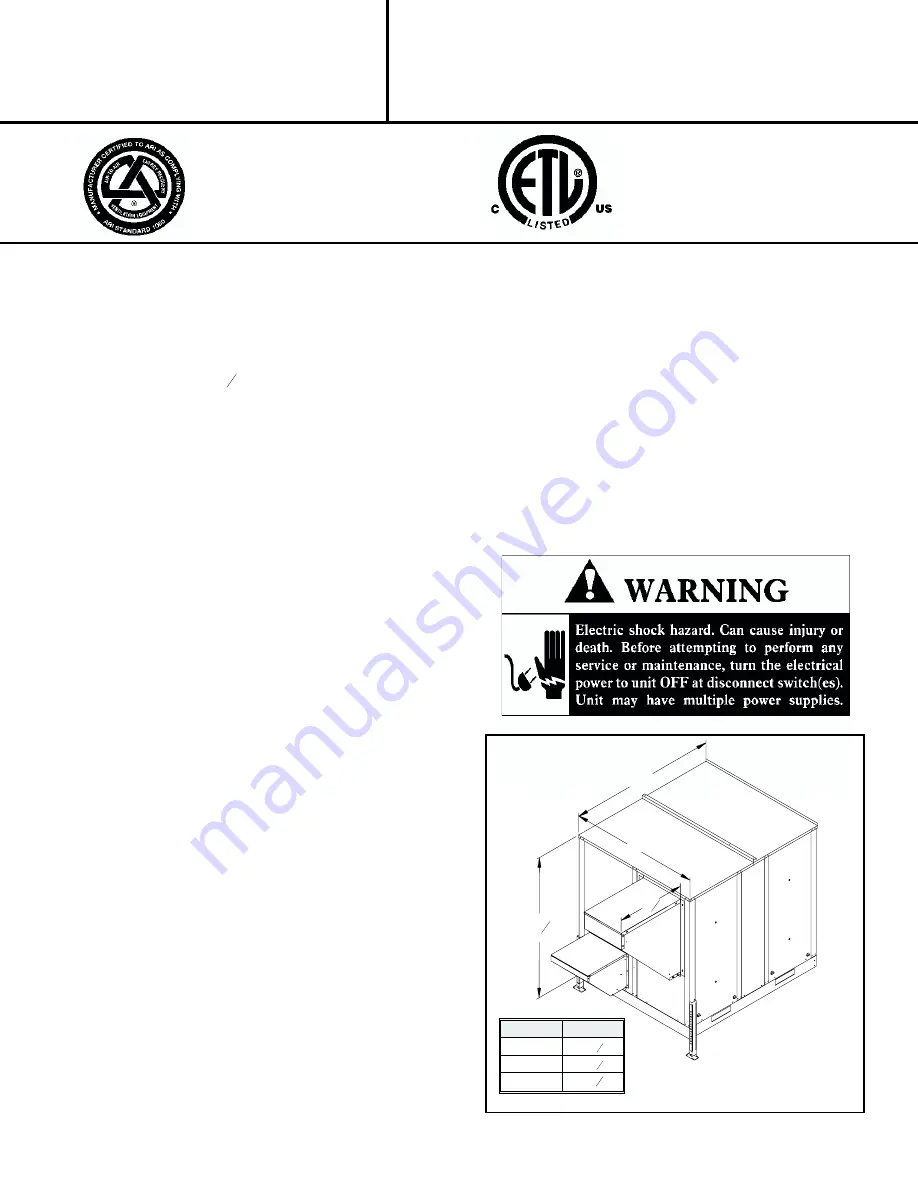

Rigging Unit For Lifting

1- Maximum weight of unit is —- 1500 Lbs. (Crated)

2- Remove crating. Then remove access panel to retrieve

bag assembly. Replace access panel.

3- All panels must be in place for rigging.

4- Lifting lugs are supplied with the unit. Loosen machine

bolts and rotate lifting lug.

Energy recovery COMPONENT certified

to the ARI Air-to-Air Energy Recovery

Ventilation Equipment Certification

Program in accordance with ARI

Standard 1060-2000 . Actual performance

in packaged equipment may vary.

ETL Certified per UL 1995

and CSA 22.2

INSTALLATION

INSTRUCTIONS

MAXA-MI$ER™

UNITARY ENERGY RECOVERY VENTILATOR

MODEL VR036A15H/25H & VR046A15H/25H

& VR062A15M/H/25M/H (STATIONARY)

035-19269-000-A-0203

60

57

3

8

A

30

1

2

MODEL#

A

VR036

46

5

8

VR046

52

5

8

VR062

58

7

8

Summary of Contents for MAXA-MISER VR036A15H

Page 10: ...PAGE 10 ...