INSTALLATION OPERATION & MAINTENANCE

BELT DRIVE AIR HANDLERS

New Release

115.22-NOM5 (704)

YSHW, YSHX

ATTENTION: READ THIS MANUAL AND ALL LABELS ATTACHED TO THE UNIT CAREFULLY

BEFORE ATTEMPTING TO INSTALL, OPERATE OR SERVICE THESE UNITS! CHECK UNIT

DATA PLATE FOR ELECTRICAL SPECIFICATIONS AND MAKE CERTAIN THAT THEY AGREE

WITH THOSE AT POINT OF INSTALLATION. RECORD THE UNIT MODEL AND SERIAL NO.

IN THE SPACE PROVIDED. RETAIN FOR FUTURE REFERENCE.

Model No._____________________

Serial No.___________________

INSTALLER’S RESPONSIBILITY

Installer Please Note: This equipment has been tested and inspected. It has been shipped free from defects from

our factory. However, during shipment and installation, problems such as loose wires, leaks or loose fasteners

may occur. It is the installer’s responsibility to inspect and correct any problems that may be found.

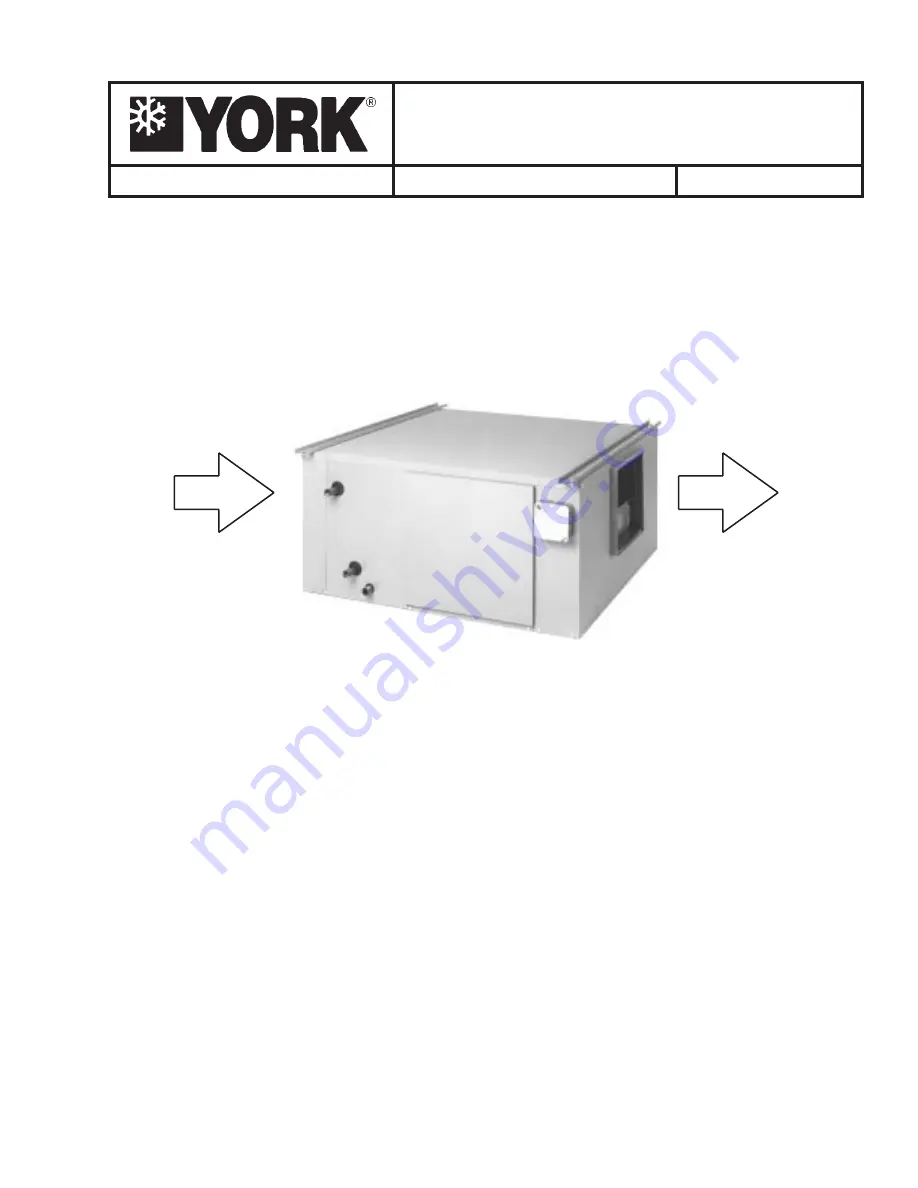

MODELS:

AIRFLOW

AIRFLOW

(RIGHT HAND UNIT SHOWN)