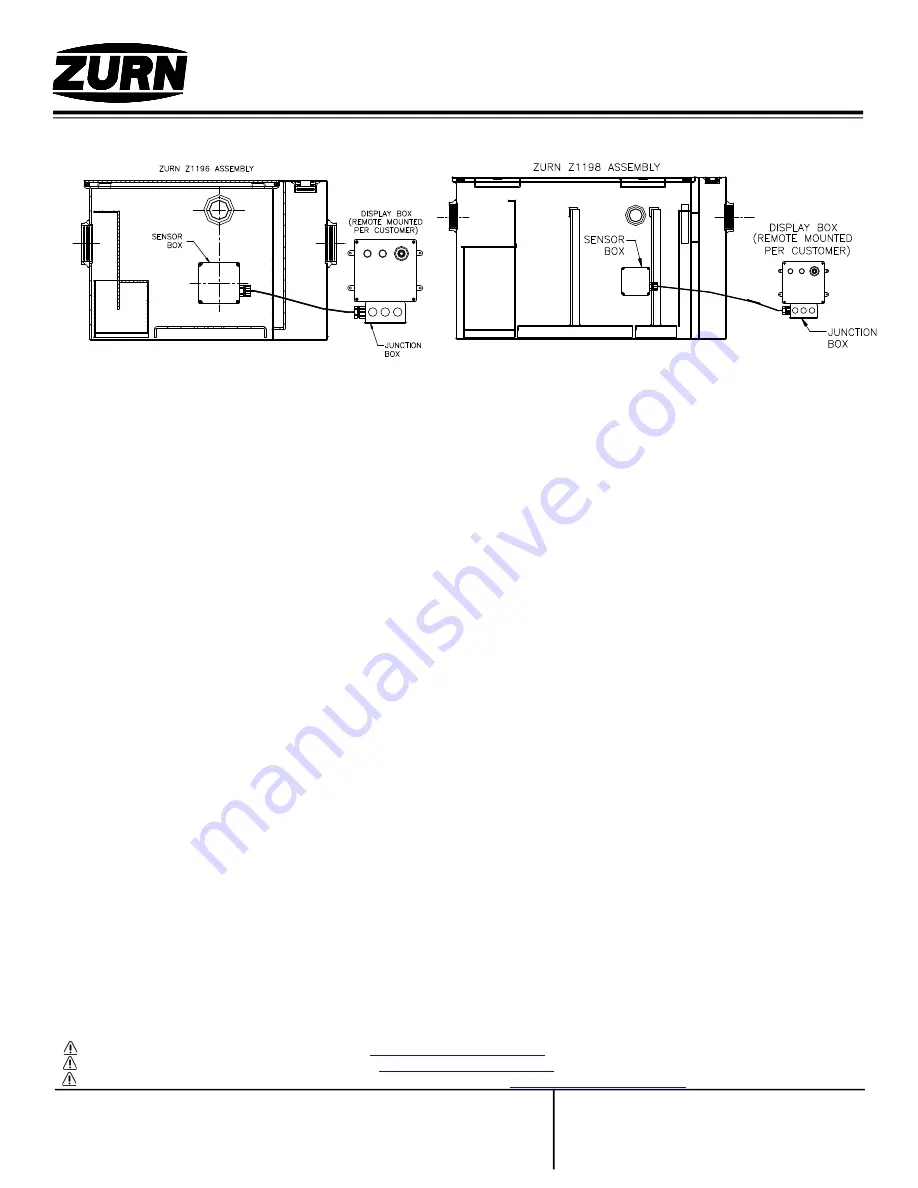

Z1196/98 OIL INTERCEP TOR

WITH OIL LEVEL SENSOR

OPERATION AND MAINTENANCE INSTRUCTIONS

Zurn Industries, LLC

|

Specification Drainage Operation

1801 Pittsburgh Avenue, Erie, PA U.S.A. 16502 · Ph. 855-663-9876, Fax 814-454-7929

In Canada

|

Zurn Industries Limited

3544 Nashua Drive, Mississauga, Ontario L4V 1L2 · Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com

Rev.

B

Date:

04/10/2018

C.N. No.

139851

Form No. IT55

Page

1 of 3

®

Dimensional Data (inches and [ mm ]) are Subject to Manufacturing Tolerances and Change Without Notice

Zurn oil interceptors with oil level sensors are efficient appliances designed to separate oil from water.

Safety Warnings

• Do Not Apply power before you read and complete Start-Up list.

• Do Not remove electrical enclosure cover when main cover is open and electricity is on.

• Do Not expose electrical components to water or oil.

• Caution - Do Not apply power until all provisions of Personal Safety Procedure #29CFR 1910.335

and Lockout and Tag Procedure #29CFR 1910.147 are in Compliance.

Installation

The Zurn Oil Interceptors with oil level sensors must be installed in accordance with the oil Interceptor Installation

Instructions (Form #IT84) and in compliance with local codes and regulations.

All Zurn Oil Interceptors with oil level sensors are FOR ON THE FLOOR INSTALLATION ONLY.

Variables That Might Affect Operation

Operators and users of Zurn oil interceptors must be familiar with the variables which may adversely affect the

efficiency of the interceptor. These are as follows:

1. Velocity of Incoming Water...A higher velocity of water will contribute to a more turbulent mixture. This will

slow the separation process and thereby reduce efficiency.

2. Ratio of oil to water...The higher the ratio of oil to water, the lower the efficiency.

3. Specific gravity (weight) of the oil...Oil with a lower specific gravity will rise to the surface much quicker, while

oil with a higher specific gravity will have a tendency to linger toward the bottom, taking a longer time

to surface.

4. Possible presence of detergents in the system...Oil cutting detergents will break the oil into minute particles

that can pass through the interceptor.

5. Presence of large particles mixed with the oil...Particles allowed to pass into the interceptor will allow

adhesion of the oil to these particles. This reduces efficiency.

Job condition variables may warrant the use of a larger size interceptor than normal sizing indicates. This

will help to ensure efficient operation as variables change throughout the operation cycle. Local codes and job

conditions prevail and may warrant alternate sizes.

Prior to doing any trouble shooting on a unit which appears to be malfunctioning, make certain that none of the

variables which affect the operation of the unit are present.

WARNING

: Cancer and Reproductive Harm -

www.P65Warnings.ca.gov

ADVERTENCIA:

Cáncer y daño reproductivo -

www.P65Warnings.ca.gov

AVERTISSEMENT:

Cancer et effets néfastes sur la reproduction -

www.P65Warnings.ca.gov