Zurn Industries, LLC | Specification Drainage Operation

1801 Pittsburgh Avenue, Erie, PA 16502, Ph. 855.663.9876

In Canada | Zurn Industries Limited

7900 Goreway Drive, Unit 10, Brampton, Ontario L6T 5W6, Ph. 877.892.5216

www.zurn.com

WARNING:

Cancer and Reproductive Harm - www.P65Warnings.ca.gov

ADVERTENCIA:

Cáncer y daño reproductivo - www.P65Warnings.ca.gov

AVERTISSEMENT:

Cancer et effets néfastes sur la reproduction -

www.P65Warnings.ca.gov

Rev. -

Date: 4/03/2020

C.N. No. 142533

Prod. | Dwg. No. C66 Page 1 OF 3

Z1231EZ

WALL-HUNG LAVATORY ADJUSTABLE CARRIER INSTALLATION INSTRUCTIONS

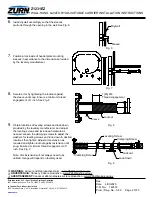

1

.

Drill holes in concrete and place anchors.

a. Two diagonally spaced anchors per foot

are required for correct installation.

b. Anchor holes for either 3/8 (A) or 1/2 (B)

(Furnished by others) See Fig.1

Note: Ensure using anchors with a minimum pullout

force of 980 lbs

2

.

Place carrier over anchors and secure with nuts

and washers

a. Torque to 25-35 ft-lbs

3.

Adjust the height of one header plate to desired

rough-in location per lavatory to be installed.

a. Hold header bracket in place

b. Loosen 4 (C) nuts on header plate

c. Loosen height adjustment bolt (D)

(on side of header)

d. Slide along upright to desired location

e. Hand tighten height adjustment bolt (D) ensuring

the header bracket does not deflect. See Fig. 3

4.

Adjust height of second header plate

a. Hold header bracket in place

b. Loosen 4 nuts (C in Fig 3) on header plate

c. Loosen height adjustment bolt (D in Fig 3)

(on side of header)

d. Place level on top of both header sleeves

and adjust height until level. See Fig 4

e. Hand tighten height adjustment bolt (D in Fig 3)

ensuring the header bracket does not deflect.

Optional - Use integrated pipe support bracket to

secure supply and drainage lines.

5.

Adjust width of the header brackets (E) per the

lavatory manufacturer’s recommendation for spacing

and tighten the 4 nuts (C) on the header bracket in a

star pattern to 30-35 ft-lbs.

Fig. 1

Fig. 3

Fig. 4

Fig. 5

B

B

A

A

Rough-in

Height

C

C

D

1

2

3

4

5

6

7

C

E

1

2

3

4

5

6

7

11

12

13

14

15

16

17

0

C

D

C

C

Rough-in

Height