4. Using the I/O Address Map

ADI16-4(FIT)GY

27

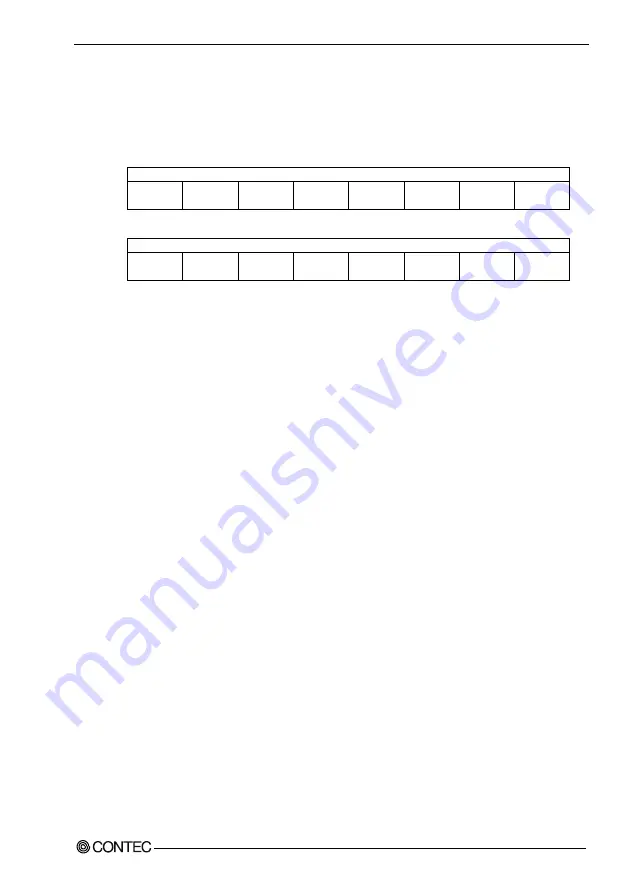

Setting sampling conditions

This step sets sampling conditions.

In terms of procedures, a sampling condition setup command is issued, and then settings data is output.

Starting

I/O

address

D7

D6

D5

D4

D3

D2

D1

D0

Output

Command

+24

(18h)

0

0

0

0

0

0

1

0

D7

D6

D5

D4

D3

D2

D1

D0

Output

FIFO Flag

+28

(1Ch)

0

0

0

0

0

Channel

Mode

Sampling

Clock

Sampling

Mode

Figure 4.17. Setting sampling conditions

-

Channel mode [D2]:

Set the mode in which the sampling is to be performed.

Select either the "single-channel mode", in which only one channel is specified, or the "multi-

channel mode", in which two or more channels are specified.

Channel Mode

[0]: Single *Initialized state

[1]: Multi

-

Sampling clock [D1]:

This option should be set when the clock mode is selected in the specification of a sampling mode.

Sampling Clock

[0]: Internal Clock

* Initialized state

[1]: Reserved

-

Sampling mode [D0]:

This step sets the conversion operation.

Specify either the "software mode", in which a specified channel is sampled once, or the "clock

mode", in which sampling is performed periodically according to clock signals.

Sampling Mode

[0]: Software Command * Initialized state

[1]: Clock

Following are examples in which sampling conditions are specified :

outp( ADR+24, 0x2 );

outp( ADR+28, ConditionData );