MobileRobots Inc.

around values 25-235. Our robot servers let you set realistic position boundaries (

MIN

and

MAX

) and

CENTER

offsets, so that your client-side code is portable from arm to arm. See following sections for

details.

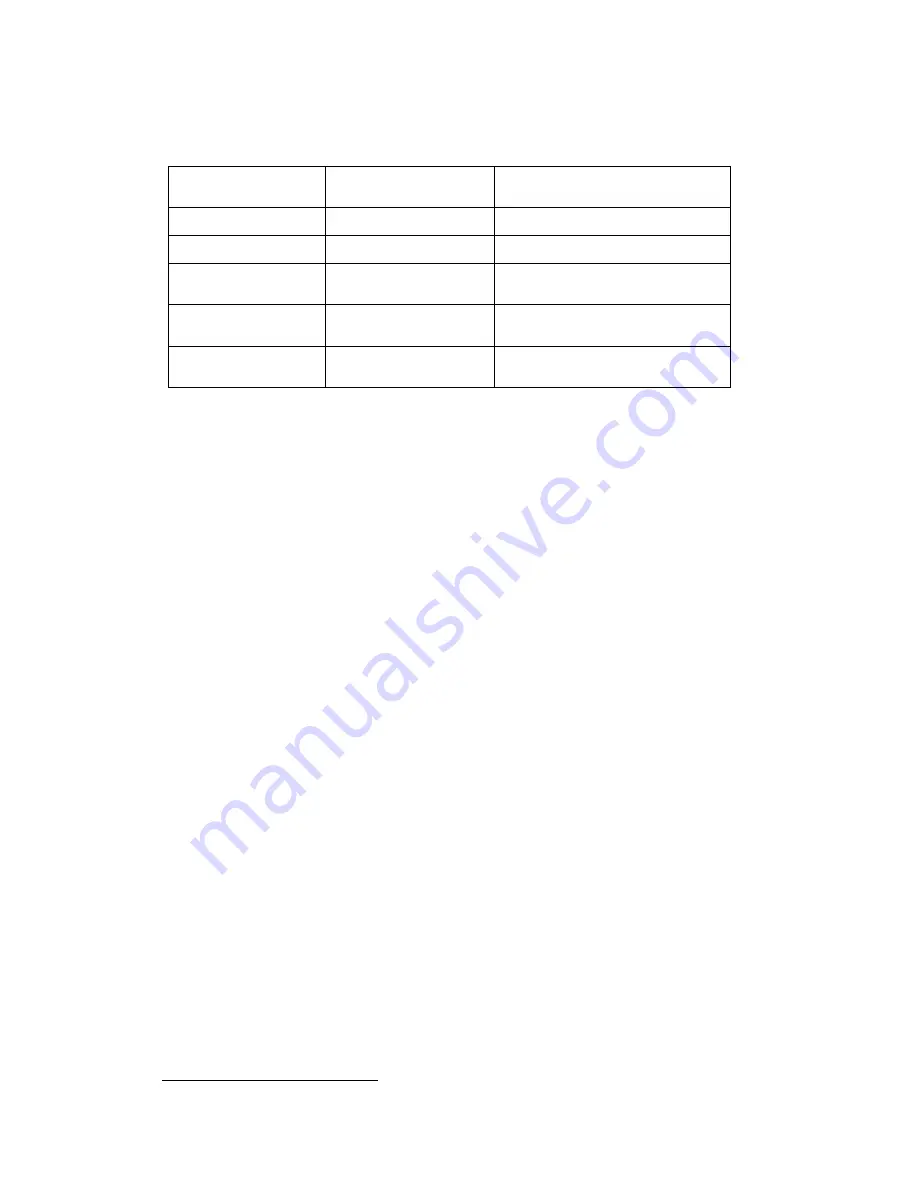

Table 1. Pioneer Arm generic commands

C

ONTROL

M

ODE

C

OMMAND

B

YTES

D

ESCRIPTION

B

OARD

R

ESPONSE

255, 12, 1

Servo Power ON

None

255, 12, 0

Servo Power OFF

None

255, 128

Request version

number

ASCII-encoded version number,

followed by CR, LF9

255, 133

Read digital port

states

0-7 corresponding to ports 0,

1 and 2, followed by CR, LF

255, s, p

Set servo joint s=0-7

to position p=0-255

None

For example, using the generic command to turn the Pioneer Arm fully clockwise around its base

(servo #1), you may send the generic command byte sequence:

255, 1, 255

Similarly, use a three byte command to power the Pioneer Arm servos: The header (255; 0xFF),

command byte 12 (0x0C), followed by a byte value of one to enable, or zero to disable servo power.

Generic Command Communications

The Pioneer Arm’s controller is attached to the

AUX

serial port on your C166, to either the

AUX1

or

AUX2

serial port on your H8S-, or to either the

AUX1,

AUX2,

or

AUX3

serial port on your SH2-based

Pioneer controller.

TTY2

command #42 to send generic commands from your client

software to the Pioneer Arm controller through

AUX1

; command #66 (

TTY3)

for

AUX2

; or command

#60 (

TTY4

) for

AUX3

. Include the Pioneer Arm’s generic command as the integer or string argument.

To retrieve responses from the Pioneer Arm controller using generic commands, use the respective

GETAUX

commands (#43, #67, #61 for

AUX1-3

) and corresponding

SERAUXpac

(types 176, 184, and

200, respectively) server information packet.

Command and packet details are in your robot’s

Operations Manual

. MobileRobots’ ARIA client-

development environment supports these functions, too.

Pioneer Controller Arm Servers

Your robot’s controller has software with advanced control functions for safe and convenient operation

of the Pioneer Arm. These include commands to enable and disable power to the arm’s servos, to

move the arm to a new position—joint-by-joint and each at a controllable speed—and to query for

current arm positions and status. The servers also include safety watchdogs and which act to

minimize power consumption as well as help protect your Pioneer Arm and surroundings from

damage.

Client Commands

P2OS, AROS, and ARCOS all support identical servers for control of the Pioneer Arm. Commands

originate in your client software and thereby require that you establish a client-server connection

between your PC and the robot’s controller. After connecting, your client software must tell the servers

to power the Pioneer Arm’s servos before you can send position commands. Note that the arm always

starts a client-server connection in its

HOME

position and automatically returns to that position when

servo power is set to OFF, including at the termination (

CLOSE

) of a client-server connection session.

9

Carriage return (13; 0x0D) and line-feed (10; 0x0A) characters.

11

10

Depends on physical attachment and ArmPort setting in FLASH. See following chapters for details.