a larger motor driver.

• Second, since the voltage is regulated, the motors will run the same speed as the batteries

drop from 5.5 down to 3.5 V. You can take advantage of this when programming your 3pi, for

example by calibrating a 90° turn based on the amount of time that it takes.

• Third, at 9.25 V, all five of the IR LEDs can be powered in series so that they consume the

lowest possible amount of power. (Note that you can switch the LEDs on and off to save even

more power.)

One other interesting thing about this power system is that instead of gradually running out of power

like most robots, the 3pi will operate at maximum performance until it suddenly shuts off. This can take

you by surprise, so you might want your 3pi to monitor its battery voltage.

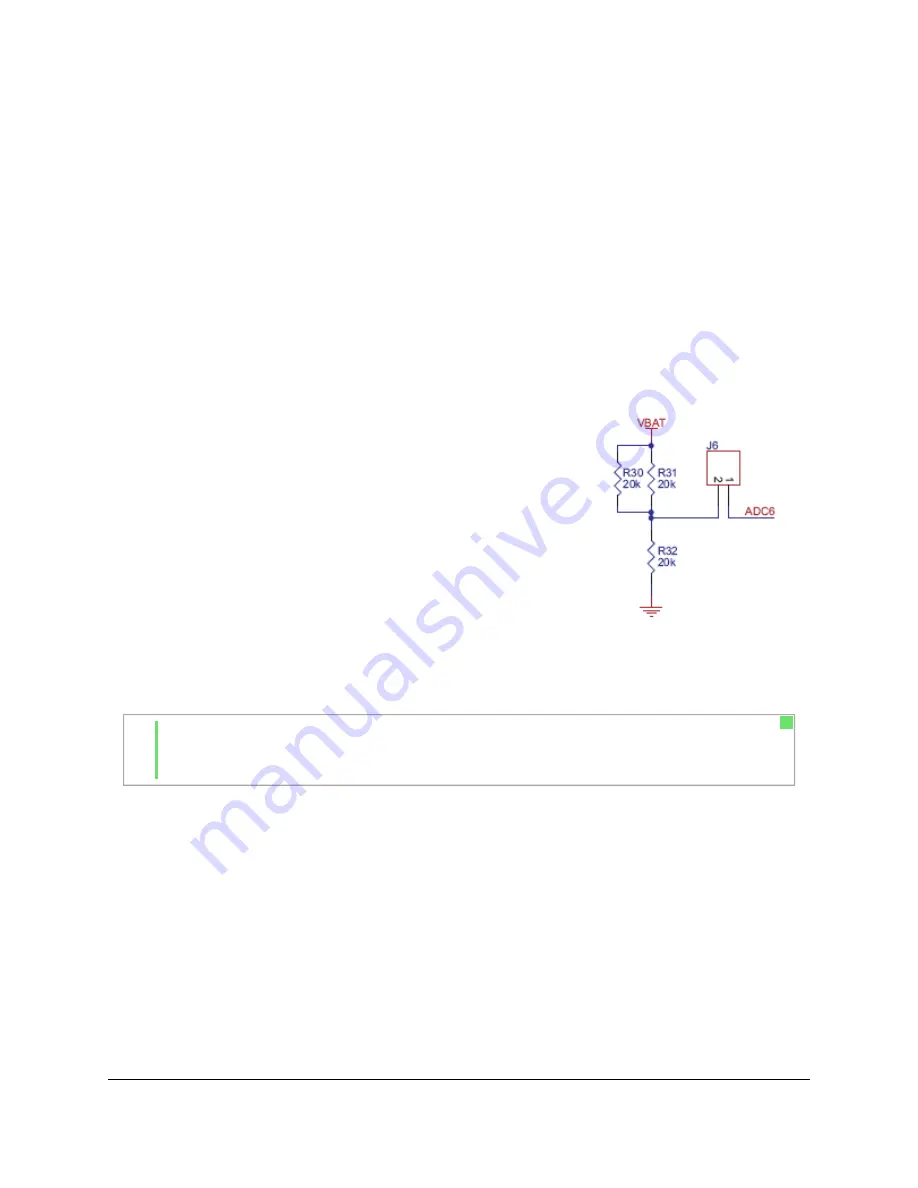

A simple circuit for monitoring battery voltage is built in to the 3pi.

Three resistors, shown in the circuit at right, comprise a voltage

divider that outputs a voltage equal to two-thirds of the battery

voltage, which will always be safely below the main microcontroller’s

maximum analog input voltage of 5 V. For example, at a battery

voltage of 4.8 V, the battery voltage monitor port ADC6 will be at a

level of 3.2 V. Using 10-bit analog-to-digital conversion, where 5 V is

read as a value of 1023, 3.2 V is read as a value of 655. To convert

it back to the actual battery voltage, multiply this number by

5000 mV×3/2 and divide by 1023. This is handled conveniently by

the

read_battery_millivolts_3pi()

function (provided in the Pololu

AVR Library; see

for more information), which averages ten samples and returns the battery

voltage in mV:

5.c. Motors and Gearboxes

1

2

3

4

unsigned

int

read_battery_millivolts_3pi()

{

return

readAverage(6,10)*5000L*3/2/1023;

}

Pololu 3pi Robot User’s Guide

© 2001–2019 Pololu Corporation

5. How Your 3pi Works

Page 15 of 85