SIMPRO-100

Control Equations & Relay Logic

B

PRIM-2400C

143

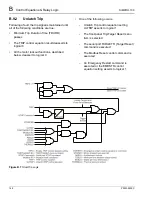

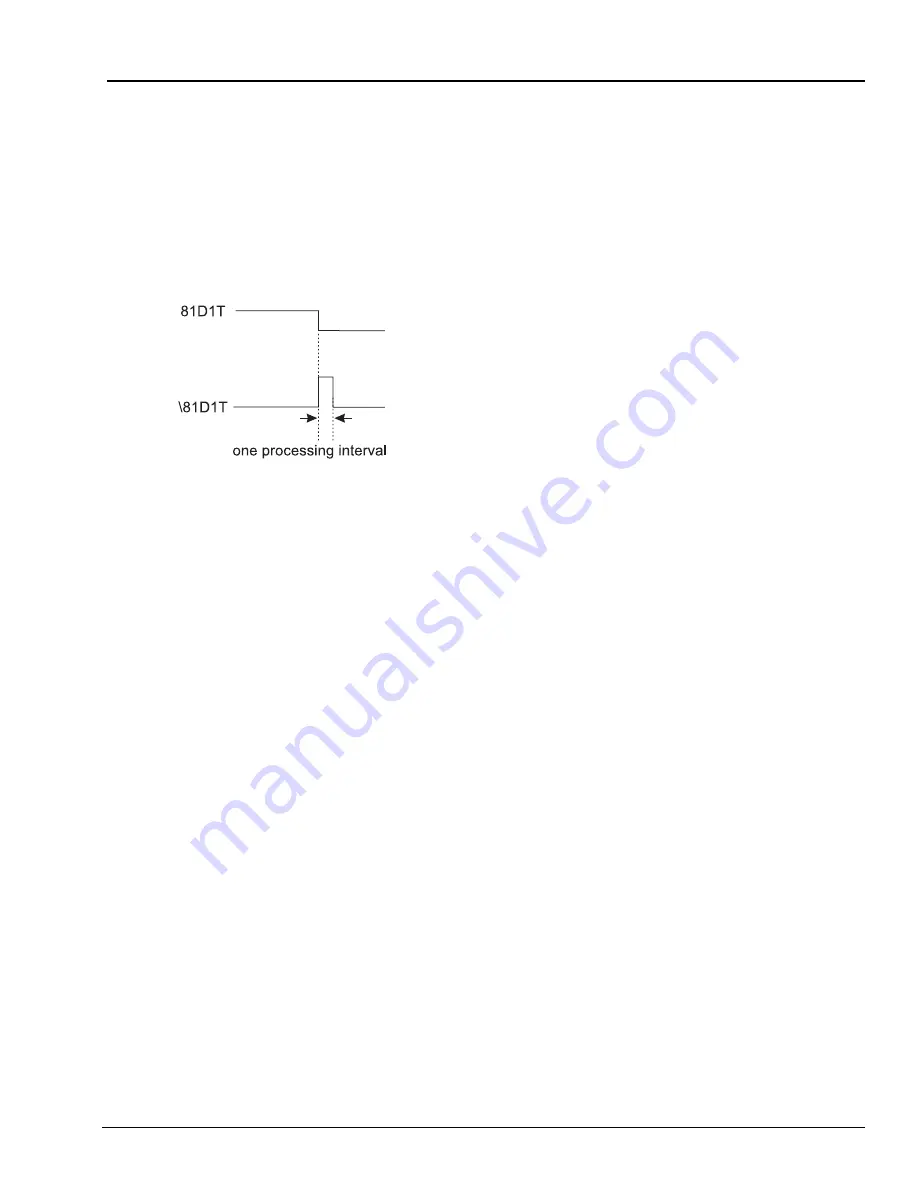

When frequency goes above the corresponding

pickup level 81D1P, Relay Word bit 81D1T

deasserts and an event report is generated (if the

relay is not already generating a report that

encompasses the new transition). This allows a

recovery from an underfrequency condition to be

observed. Figure B.2 demonstrates the action of

the falling-edge operator [\] on the

underfrequency element in setting ER.

Figure B.2

Result of Falling-Edge Operator on a

Deasserting Underfrequency Element

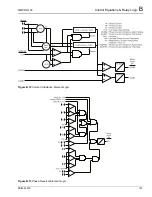

B.4.1.4 Control Equation Rising-Edge

Operator [/]

Use the rising-edge operator [/] with individual

Relay Word bits to cause a single

processing-cycle assertion when the Relay Word

bit changes state from logical 0 to logical 1. Do

not apply the [/] operator to groups of elements

within parentheses.

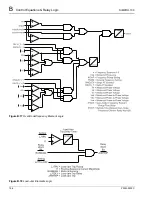

B.4.1.5 Control Equation Parentheses

Operator [( )]

Use parentheses to logically combine multiple

elements. More than one set of parentheses [( )]

can be used in a control equation setting.

Parentheses cannot be “nested” (parentheses

within parentheses) in a control equation setting.

For example, the following control equation

setting has two sets of parentheses:

Equation B.4

In the above example, the logic within the two

sets of parentheses is processed first and then

the two results are ANDed together. The example

equation could be used to provide simple motor

breaker failure protection.

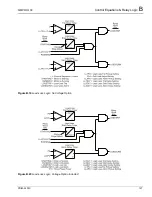

B.4.1.6 Control Equation NOT

Operator [!]

Use the NOT operator [!] to invert a single Relay

Word bit and also to invert the result of multiple

elements combined within parentheses.

B.4.1.7 Set Control Equations Directly to

Logical 1 or Logical 0

To define a condition always picked up or always

dropped out, you can set control equations

directly to:

1 (logical 1) or 0 (logical 0)

If you set a control equation setting directly to 1, it

is always asserted/on/enabled. If you set a

control equation setting equal to 0, it is always

deasserted/off/disabled.

B.4.2

All Control Equations Must

Be Set

If you use control equations, every one needs to

be set by making it equal to one of the following:

•

A single Relay Word bit

•

A logical combination of Relay Word bits

•

Directly to logical 1

•

Directly to logical 0

If you are satisfied with the factory default logic

setting, you may leave the control equation

setting unedited.

SV4 = (SV4 + IN2 + TRIP) • (50PIT + 50N1T)

Summary of Contents for SIMPRO-100

Page 1: ...SIMPRO 100 Motor Protection Relay Instruction Manual Document No PRIM 2400C ...

Page 12: ...Contents SIMPRO 100 x PRIM 2400C ...

Page 16: ...Contents SIMPRO 100 xiv PRIM 2400C ...

Page 42: ...3 SIMPRO PC Software SIMPRO 100 40 PRIM 2400C ...

Page 100: ...6 ASCII Serial Port Operation SIMPRO 100 98 PRIM 2400C ...

Page 127: ...SIMPRO 100 Event Analysis 9 PRIM 2400C 125 Figure 9 2 Example SER Report ...

Page 136: ...10 Maintenance Troubleshooting SIMPRO 100 134 PRIM 2400C ...

Page 138: ...A Firmware Versions SIMPRO 100 136 PRIM 2400C ...

Page 206: ...D SIMPRO PC Compatibility Features SIMPRO 100 204 PRIM 2400C ...

Page 214: ...E Motor Thermal Element SIMPRO 100 212 PRIM 2400C ...

Page 230: ...F SIMPRO 100 Relay Settings Sheets SIMPRO 100 228 PRIM 2400C ...

Page 239: ......