- 16 -

5.4.3 Command

[48, wo]

Value

Function

00

Normal operation

01

Save parameters on EEPROM

02

Save and activate Preset / Offset

04

Load and save default parameters

After having set a new value in some register, use the

Save parameters on EEPROM

function in this register

to store it. Set “01” in the register.

After having set a Preset / Offset value, use the

Save and activate Preset / Offset

function in this register to

both store and activate the preset / offset at the same time. Set “02” in the register.

Load and save default parameters:

default parameters are set to allow the operator to run the device for

standard operation in a safe mode. As soon as the command is sent the default parameters are uploaded and

activated. All parameters which have been set previously are overwritten, thus previously set values are lost.

The complete list of machine data and the relevant default parameters preset by WayCon are available at the

of this manual. Set “04” in the register.

ATTENTION:

As soon as the

Load and save default parameters

command is sent, all parameters which have

been set previously are overwritten, thus previously set values are lost!

As soon as the command is sent, the register is set back to "00" (

Normal operation

) automatically.

Wait min. 30 ms (EPROM writing time) before using a new function.

Default = 00 (

Normal operation

)

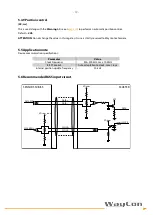

5.4.4 Configuration

[49, rw]

Bit

Function

bit = 0

bit = 1

0

Not used

-

1

Set preset / offset

Preset

Offset

2

Enable preset / offset

Enable

Disable

3

Not used

-

4

Not used

-

5

Output code

Gray

Binary

6

Counting direction *

Standard

Inverted

7

Not used

-

* it affects the absolute position information, not the AB incremental signals

Set preset / offset

This parameter is available only if the

Enable preset / offset

parameter is set to ENABLE. It allows to activate

either the preset function (

Set preset / offset

= PRESET) or the offset function (

Set preset / offset

= OFFSET);

the Preset or Offset value has to be set in the Preset / Offset register. After having enabled the preset / offset

functions (

Enable preset / offset

= ENABLE), this item allows to activate either the preset function or the offset

function. The value set in the Preset / Offset register will have a different meaning depending on the value of

this parameter whether it is set to PRESET (0) or OFFSET (1). In the first case (

Set preset / offset

= PRESET) the

Preset / Offset register is used to set the preset value; while in the second case (

Set preset / offset

= OFFSET)

the Preset / Offset register is used to set the offset value. To activate the preset / offset value use the Save and

activate Preset / Offset function in the Command register (set “02” in the register 48). For any information on

the preset and offset functions refer to the Preset / Offset register on

Default = 0 (

Preset

)

Summary of Contents for MXS2

Page 1: ...Magnetic Scale MXS2 Manual...