ADTECH9 Series CNC Programming Manual

_

necessary hole processing parameters except F must be re-specified,

even if these parameters aren’t changed.

7

X_Z_

X axis positions the instruction point and processes the hole, and hole

processing parameter Z is changed in this segment.

8

G89X_Y_

Position the XY instruction point and process the hole, and the hole

processing mode is changed to G98. R, P are specified by 7, and Z is

specified by 7.

9

G01X_Y_

The fixed cycle mode is canceled, and all hole processing parameters

except F are canceled.

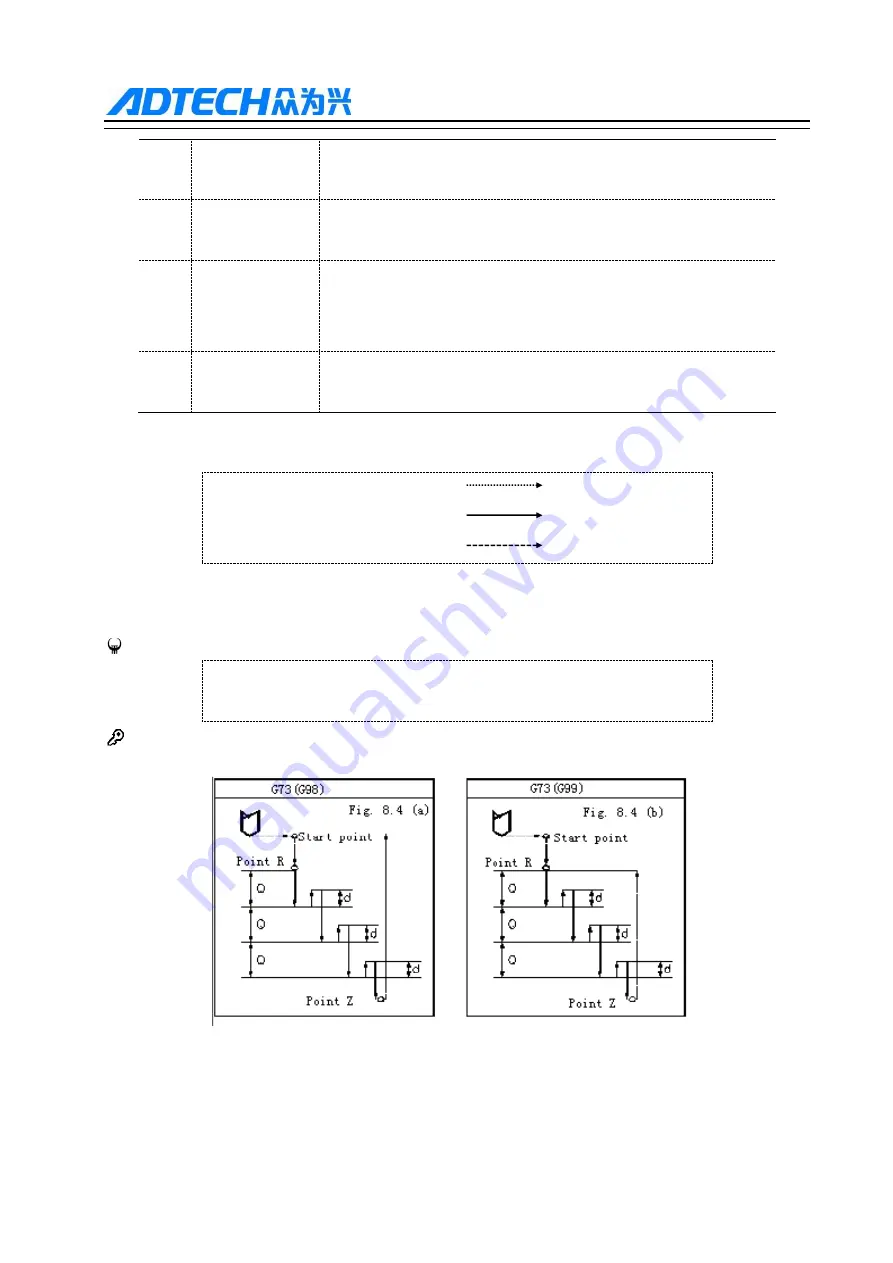

In the following diagrams, we use the modes below to indicate the feeding of every segment:

Indicate motion in quick feeding speed

Indicate motion in cutting feeding speed

Indicate manual feeding

2.4.1.

High-speed deep-hole drilling cycle (G73)

Format:

Format: G73 X_ Y_ Z_ R_ Q_ F_

Details:

High Speed Deep Hole Drilling Cycle Diagram

The feeding from point R to point Z is finished in several segments; after cutting every segment, Z axis lifts for

certain distance, and then executes cutting feeding for next segment.

The distance that Z axis lifts every time is d, which is specified by parameter P1.015,G73(M)circulating tool

Summary of Contents for CNC9640

Page 1: ...ADTECH9 Series CNC Programming Manual ...

Page 21: ...ADTECH9 Series CNC Programming Manual Workpiece Coordinate System Diagram ...

Page 44: ...ADTECH9 Series CNC Programming Manual 2 Occasions that inner corner rotates ...

Page 45: ...ADTECH9 Series CNC Programming Manual ...

Page 62: ...ADTECH9 Series CNC Programming Manual Manual insertion ...

Page 65: ...ADTECH9 Series CNC Programming Manual Tool radius compensation start and axis Z cut in action ...

Page 117: ...ADTECH9 Series CNC Programming Manual ...

Page 118: ...ADTECH9 Series CNC Programming Manual ...

Page 142: ...ADTECH9 Series CNC Programming Manual ...

Page 143: ...ADTECH9 Series CNC Programming Manual ...