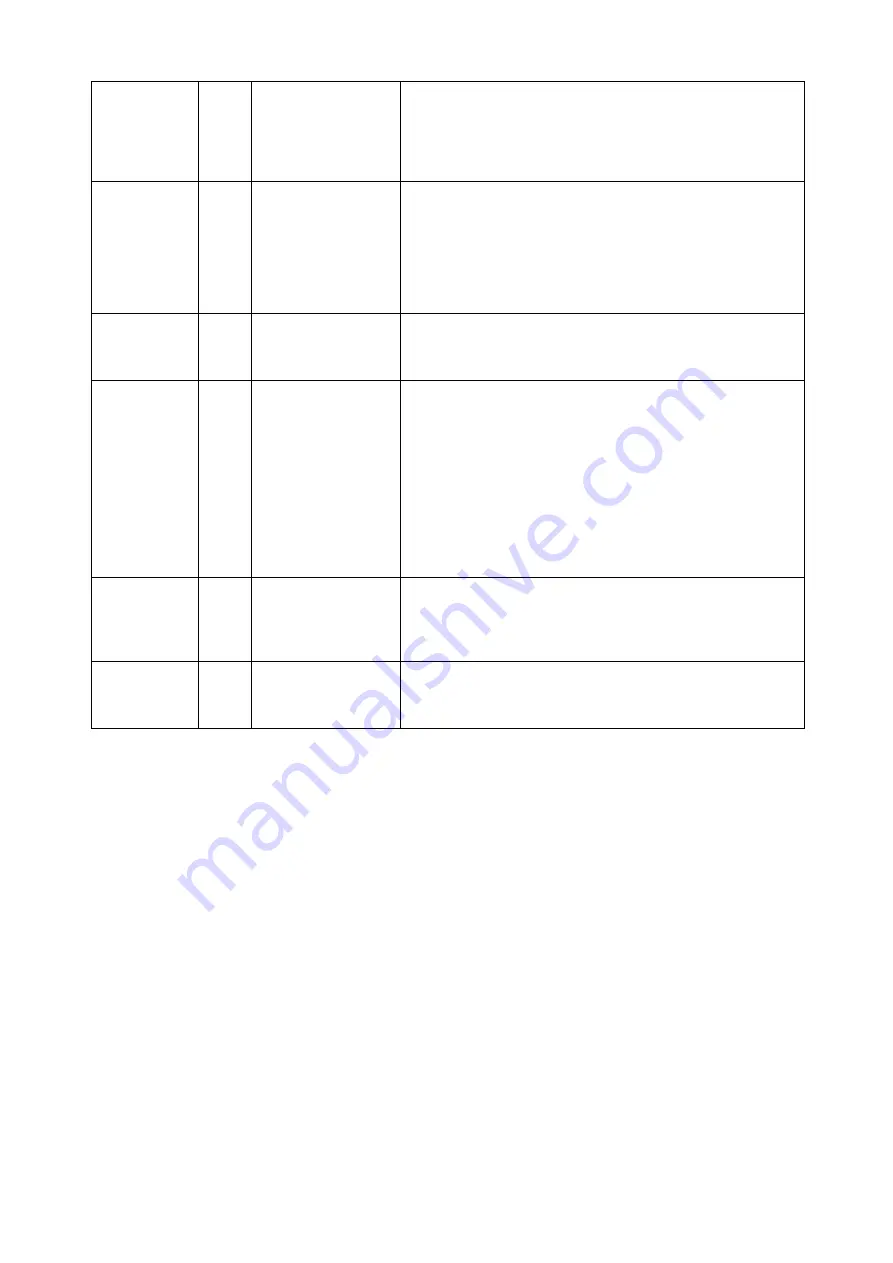

Page 5

Poll

O/79

0 - RS232

1 - TCP

2 – CAN

Request a single data packet (in the current active format) for

the channel selected. Data streaming should be set off before

using this command. Note that there is no positive

acknowledge for this command. This command is not valid for

logging to Internal RAM.

Span

A/65

None

Request a ‘span’ operation. The unit should have been recently

rezeroed, then the appropriate span pressure (as selected from

the setup software) applied to the scanner. Requesting a span

operation will then calculate the span correction coefficient for

each channel. All rezero values and span coefficients are then

written to the unit’s EEPROM (NOT to the scanner), and the

calibration tables rebuilt using these new values.

Reset Linear

Calibration

E/69

None

Resets the linear calibration (ie zero and span values) held

within the unit to 0 and 1.0 respectively for all channels. A

calibration table rebuild is then performed.

Hardware

Trigger

T/84

byte = 0xab

a = 0 Disable

a = 1 Enable

b = 0 RS232

b = 1 TCP

b = 2 CAN

b = 3 Internal RAM

b = 4 Internal RAM

(stop on full)

Enables or disables the hardware trigger on the selected

channel. Note that there is no positive acknowledge for this

command.

Assuming a valid hardware trigger is detected for the duration,

Internal RAM data streaming will either log continuously,

wrapping (and therefore overwriting) when the end of available

RAM is reached, or will stop when the RAM is full (and

automatically disable the hardware trigger), depending on the

parameter.

Start Internal

RAM Dump

I/73

0 - RS232

1 - TCP

2 - CAN

Starts the internal RAM dump, sending data using the comms

channel chosen by the parameter. The first packet is sent

immediately and consists of a 9 byte header (only 6 bytes for

CAN - see later)

Internal RAM

Dump

Handshake

J/74

None

Handshake command to indicate previous packet was received.

Must be sent after header packet & all subsequent data

packets.

Figure 2.2, The Available User Command Set for the microDAQ.