Page 6

3. Status Data Format.

Status data is not currently supported over the CAN channel, however for RS232 and TCP

connections, status data may be requested from the microDAQ as three forms – ‘short’, ‘full’ and

‘with temp’. The short form returns 4 bytes, the 16 bit status word delimited by the ASCII

characters ">" and "<", the less significant byte is returned before the more significant. The bit

assignment is shown in figure 3.1.

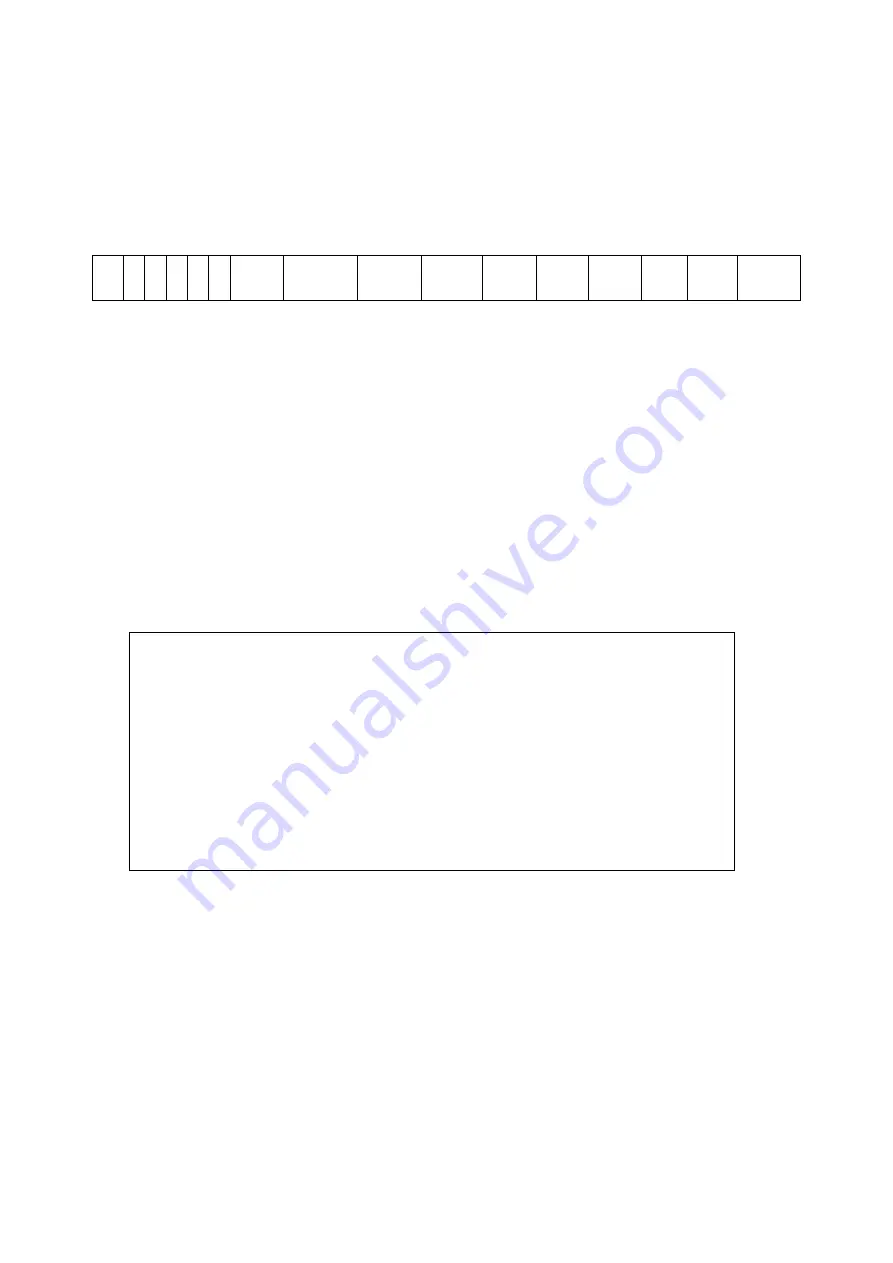

15

I-daq

conn.

Hardware

Trigger

Active

Derange

acvtive

DTC

conn.

CAN

Active

TCP

Active

RS232

active

Cal.

table

Span

Rezero

Figure 3.1, Status word bit assignment.

Requesting the status 'with temp.' returns the short status 4 bytes, followed by the temperature

data. For a non DTC scanner, a single value (ASCII unsigned 14 bit) representing the read

temperature voltage is appended to the status bytes. For a DTC application, all active channels

are returned in ascending order as comma delimited ASCII engineering units (ie degrees C).

The 'full' status data contains the above, followed by fields for the setup options of the microDAQ.

Each field is comma delimited, and its function is indicated in plain text between square

parentheses. On/off is indicated by 1/0. An example 'full' status string is shown in figure 3.2 for a

microDAQ with a non DTC scanner. Note that the figure for full scale includes the derange constant

(ie scanner full scale x derange constant) if the derange option has been selected in setup.

Figure 3.2, Full status information.

*>Mó<8198,[Full scale] 15.00000000,[Active channels] 32,[DTC active]

0,[CAN channels] 32,[TCP channels] 32,[RS232 channels] 32,[CAN rate]

OFF,[TCP rate] OFF,[RS232 rate] OFF,[CAN protocol] 16 LE,[TCP protocol]

16 LE,[RS232 protocol] 16 LE,[Press. input impulse] 1,[Temp. input impulse]

0,[Press. input power] 3,[Temp. input power] 0,[Press. output power] 0,[Reset

on delivery] 0,[Temp. compensation] 0,[Period] 10m,[IP] 0.0.0.0,[Mask]

0.0.0.0,[Gateway] 0.0.0.0,[CAN timing] (BRP) 5 (TSEG1) 2 (TSEG2) 0 (SJW)

1,[CAN message] 00n,[Rezero order] 4,