Technical Manual Cold Storage Controllers TKP / TKC x130 - x140

Page 9

'Physical' and 'virtual' sensors

1

. Each 'physical' (real) sensor is able to fulfill up to 3

functions at the same time (see Assignment Page),

any sensor is able to do the same job.

Up to 6 control sensors can be assigned the same

time. The warmest of them initiates the cooling

function.

2

. It is possible to create a 'virtual' sensor to realize

different kinds of averaging, e.g. multiple sensors in

a huge room or averaging of inlet and outlet sensor

in a chest freezer. The 'virtual' sensor resp. value

(

sensor 7

) follows from the selectable emphasis of

the sensors which must have an effect on the result

(

weighting 1-6

, Assignment Page). The functions

assigned to this 'sensors' (

funct sens. 7a-c

, As-

signment Page) are the same as the functions for

the 'physical' sensors.

Example

: If the 'physical' sensor 1 got the function

"

con

" (control sensor) and also the 'virtual' sensor,

then the warmer one initiates refrigeration.

● Selection of a "virtual sensor":

- Assignment of a function by "

funct sens7a-c

"

● Selection of a 'physical' sensor which must have

an effect on the result :

- Activating of the sensor by assigning a

function (e.g. display only sensor)

● Set weighting for the selected sensor

(

weighting 1-6

).

The sum of all emphasis values must be

100%.

Example

:

If sensor 1 and sensor 2 must have an effect on

the result and you set "

weighting 1

" to "30%"

and "

weighting 2

" to "60%", then you get the error

message "

SEL

" (assignment error).

Further causes for the error message "

SEL

"

● The sum of all emphasis parameters is 100%,

but no virtual sensor function is selected

● All 4 emphasis values are set to '0' and a

'virtual' sensor function is assigned

● A physical sensor is switched off, but an

emphasis value > 0 is selected.

Example 1, Chest Freezer:

For the detection of the actual value, inlet and outlet

sensor must be used. Sensor 1 is mounted at the

suction side (inlet) and must have an 60% influence

on the result. Sensor 2 is mounted at the outlet and

must have an 40% influence.

- set "

weighting 1

" to "60"

- set "

weighting 2

" to "40"

- set "

funct sensor 7a

" to "con" (control sensor)

Example 2, huge room, standard application

Sensors 1-3 must measure the rooms temperature,

an arithmetic average must be calculated, sensor 4 is

the defrost limitation sensor in the evaporator.

- set "

weighting 1+2

" to "33" and "

weighting 3

"

to "34"

- set "

funct sensor 7a

" to "con" (control sensor)

- set "

funct sensor 4a

" to "df1"

Special Function

If an emphasis parameter value is set to

100% (others to 0), up to 6 functions can

be assigned to the corresponding physical sensor.

This may be of interest for applications where

more than 3 sensor functions are used.

M

L

M

L

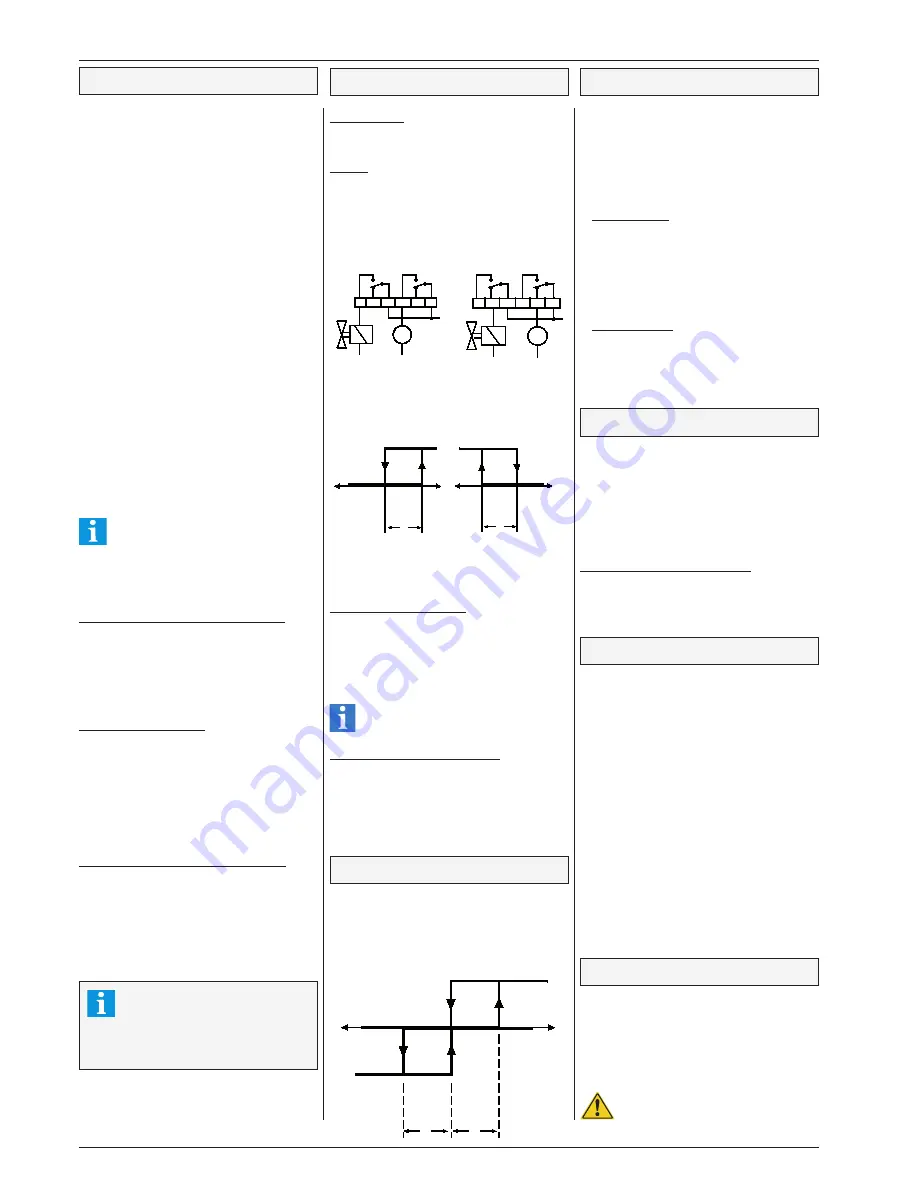

cool.

mode

freez..

refrig relay fan relay

refrig relay fan relay

cool.

mode

refrig.

Caution

Cooling

Control circuits

This controller is able to control up to 4 independent

cooling circuits, each with an own setpoint.

Cooling

Cooling is controlled by switching the output relay.

In case of power loss or controller defects the

contacts must switch in a position which is safe for

the application. For this reason we are using the

N/O-contact for refrigeration applications (fail-safe:

open contacts). For freezing applications we use

the N/C-contacts (fail-safe: closed contacts).

This can be set by parameter

"cooling mode"

(mode page). The point of cut-off is always the

valid setpoint. The selection of this parameter

also affects to the switching characteristic of the

fan relay.

The refrigeration relay can be disabled via interface

(see chapter "networking via E-Link").

Low temperature Limitation

Can be used e.g. for refrigerated shelfs with roller

blinds to limit the temperature at the air outlet du-

ring night operation. When the temperature at the

alarm sensor falls below the limit set by "

warn low

limit

" (Setpoint page) cooling will switch off. This

value is the threshold for the undertemperature

alarm at the same time.

The undertemperature limitation cannot

be switched off and is also active with

disabled low temperature warning.

Refrigeration delay after power up

The start of refrigeration after power-up resp.

mains loss can be delayed by parameter "

re-

frDlyAftMnsOff

" (Setpoint Page). In plants with

many cold storages this function prevents that

after power-up all solenoid valves open at the

same time, even though not enough machine

power is present yet.

freezing

relay ON

cooling =

relay OFF

warm

cold

setpoint

Hysteresis

cooling = relay ON

cold

warm

setpoint

hysteresis

relay OFF

refrigeration

notice

Heating function

For one relay it is possible to assign the function

of heating circuit 1. The setpoint is the cut-off of

heating and cooling at the same time:

•

for cooling at se hysteresis

and

• for heating at setpoint - hysteresis.

refrig. ON

heating ON

cold

warm

OFF

setpoint

hysteresis

hysteresis

Runtime Monitoring

The controller monitors the total running hours per

day of the cooling outputs. This values are displayed

under parameters „

run time refr. x

“ for each circuit.

One day counts from the time of the parameter

„

runtime mess at

“ (mode page) until the same time

of the next day.

Example:

"

runtime mess at

" set to 11:00.

Monitoring time range is from 11:00 o'clock day 1up

to 10:59 o'clock day 2.

The total runtime of the cooling relays over a day

will be stored and displayed (

"runtime refr. 1-4"

,

Actual Values).

A parameter „

cooling limit

“ can be set to a reasonable

value (hours per day) which, when exceeded on

three days in a sequence, will cause an alarm at

the hour programmed by „

runtime mess at

“. Then

the alarm relay will be de-activated and the alarm

LED goes on.

This alarm will be cancelled automatically 1

hour later.

Operation with a single compressor

If a single compressor is controlled by a refrigeration

relay, it is suggestive to have an idle time to prevent

the machine from damages caused by short cycle

operation. The compressor can restart only after the

timer "

compr. pause

" (setpoint page) is run down. The

remaining time up to the compressors restart can be

read at "

rem.compr pause X

" (actual page).

If a compressor must be controlled directly,

never use the cooling mode 'freezing' to

prevent compressor damages by conti-

nuous running!

Second setpoint (night operation)

For each of the 4 circuits a second setpoint is avai-

lable (

2nd setp Ch X

). This can be used for night

operation or other energy savings. The toggling

between these setpoints can be made by the internal

clock or by a digital input. The setpoint which is in

use at the moment is marked by two arrows like:

„—> -20,0°C <—“. In the actual values page you

see also if day or night setpoint is in use.

Internal toggling

The parameters „

night setpt ON

“ (mode page)

and „

night setpt OFF

“ determine the period

when the 2nd setpoint will be active. If the

function 'night settings' is assigned to one of the

digital inputs, it must be connected to mains

phase. If the internal timer is not used, set

'

night setp. ON

' and

'night setp. OFF

' times to

„OFF“.

External toggling

If the 'night settings' input is open, the 2nd

setpoint is activated all time and the internal

timer is disabled. With this digital input to mains

phase, the normal (1st) setpoint is activated

and internal timer is enabled.

Second Set of Setpoints

The controller offers two sets (layers) of setpoints,

where the first layer of setpoint is used during normal

operation and the alternative layer of setpoints with

other temperatures is used e.g. for other products

which will be stored only sometimes. For each layer

there are parameters for the setpoints, the night

setpoints, warning offsets and low temperature

warning. The names of the second set parameters

begin with '

alt

....'.

Toggling between the setpoint layers

1. internal: with parameter „

setpoint layer

“

2. external: assign function „setpoint layer“ to

a digital input. If connected to mains

phase, the 2nd layer is in use.