Operator Level Parameter Definitions:

PV - Process Value This is the temperature (or other

process variable) as measured at the sensor. This will

indicate a value within the range between the low scale

(Lo.SC) and high scale value (hi.SC). This indication

will read an error code if the temperature (process

variable) goes out of the preset span. Note items 6 and

7 of the troubleshooting guide on page 25 for the error

code descriptions.

SV - Set Point Value This parameter is the desired set

point of the process. It can be adjusted within the

range defined by the low scale (Lo.SC) and high scale

value (hi.SC). The span adjustments can be used to

limit the set point of the controller.

ASP1 - Alarm 1 Set Point Value or Dwell Time This

sets the points at which alarm 1 will energize if A1.SF

(alarm 1 special function) is set for an alarm function.

If A1.SF is selected for the dwell timer function (toon or

toof), then this becomes the timer setting in minutes.

The dwell timer starts counting when the process value

reaches the set point value. Note page 20 for more

information.

rAMP - Ramp Rate This controls the heat-up and

cool-down rate of the process. This setting is in

degrees per minute.

oFSE - Offset Value This parameter is only functional

if the integral time (automatic reset) is set to zero. The

oFSE then functions the same as manual reset to

correct the process temperature to the set point temper-

ature. If the process temperature stabilizes below the

set point, then set a positive amount of oFSE. If the

process temperature stabilizes above the set point, set

a negative amount of oFSE. Wait for the system to

stabilize and make further adjustments as required.

ASP2 - Alarm 2 Set Point Value This sets the points

at which alarm 2 will energize if A2.SF (alarm 2 special

function) is set for an alarm function. If A2.SF is

selected for cooling; the cooling cycle time, proportional

band and deadband are adjusted by parameters CCyC,

C.pb and d-b. ASP2 will then have no effect. Note

page 20 for more information.

ShiF - Display Shift A value entered here will be

added or subtracted from the process value. This offset

can be used as a correction factor if the sensor does

not read the same temperature as the item being

sensed. Note page 21 for more information.

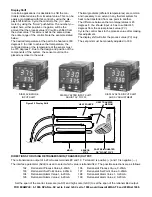

Pb, Ei and Ed - PID Values Proportional band,

Integral (reset) and Derivative (rate) time constants.

These must be set as close as possible to the process

application requirements. Note page 17 for more

information.

AhY1, AhY2 - Hysteresis of Alarm 1 and Alarm 2

The values entered here define the deadbands for the

alarms. The alarms will not change state until the

temperature is outside of the deadband.

hySE - Hysteresis of On-Off Control This parameter

defines the deadband when on-off control is used and

PID control has been disabled. For on-off control, set

Pb, Ei and Ed to 0. The output on a relay control will

not change state until the temperature is outside the

deadband. Note page 17 for further information.

Addr - Interface Address For external communica-

tions with a computer.

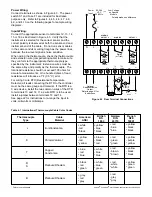

Lo.SC, hi.SC - Low/High Scale Range These

parameters are used to define the range (span) of the

control. These should be set for the requirements and

safety of your process. Refer to "Initial Operation" on

page 17 for further information. If inputs other than

thermocouples or RTDs are required, refer to page 22

for reranging directions.

PL.1, PL.2 - Power Limit These parameters are used

to limit the output percentage of power for heating or

cooling. If the control has relay or pulsed voltage

outputs, then the percentage of “on” time will be

decreased. The actual output levels will be decreased

if the control has linear current (4-20mA) or linear

voltage outputs.

inPE - Input Type This parameter is used to program

the control to the type of input sensor used.

uniE - Process Units This parameter is used to set

the display in degrees F, C or blank for engineering

units.

rESo - Display Resolution This parameter is used to

place a decimal point in the process and set point

values. A two-place decimal point can only be set if the

uniE adjustment is set to engineering units (PU).

Con.A - Control Action of Output 1 This parameter

selects heating (reverse) or cooling (direct) action for

output 1.

A1.Md, A2.Md - Alarm Mode Selection for Alarm 1

and Alarm 2 This adjustment sets the type of alarm

required: deviation alarm, band alarm or process alarm.

Refer to page 20 for more information.

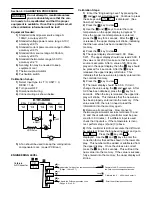

A1.SF - Alarm 1 Special Function This selects

special functions required for use with alarm 1. The

special functions include latching alarms, hold

(inhibited) function or dwell timer function. Refer to

page 20 for more information on alarms.

A2.SF - Alarm 2 Special Function This selects spe-

cial functions for alarm 2. This includes latching func-

tion, hold (inhibited) function or proportional cooling.

CyC - Proportional Cycle Time of Output 1 This sets

the proportional cycle time for output 1. This should be

set according to the type of output device used. For

mechanical relays, cycle times of 15 to 20 seconds are

used. For solid-state relays, set this adjustment to 1 or

0. For 4-20mA or other linear outputs set this to 0.

CCyC - Cooling Cycle Time Only used if A2.SF

(alarm 2 special function) has been set for cooling. Use

the same settings as the above paragraph.

C.Pb, d-b Cooling Proportional Band, Cooling

Deadband Only used if A2.SF (alarm 2 special

function) has been set for cooling. Refer to page 22 for

further information on the settings to be used for cooling

output.