6- 45

Calculation app

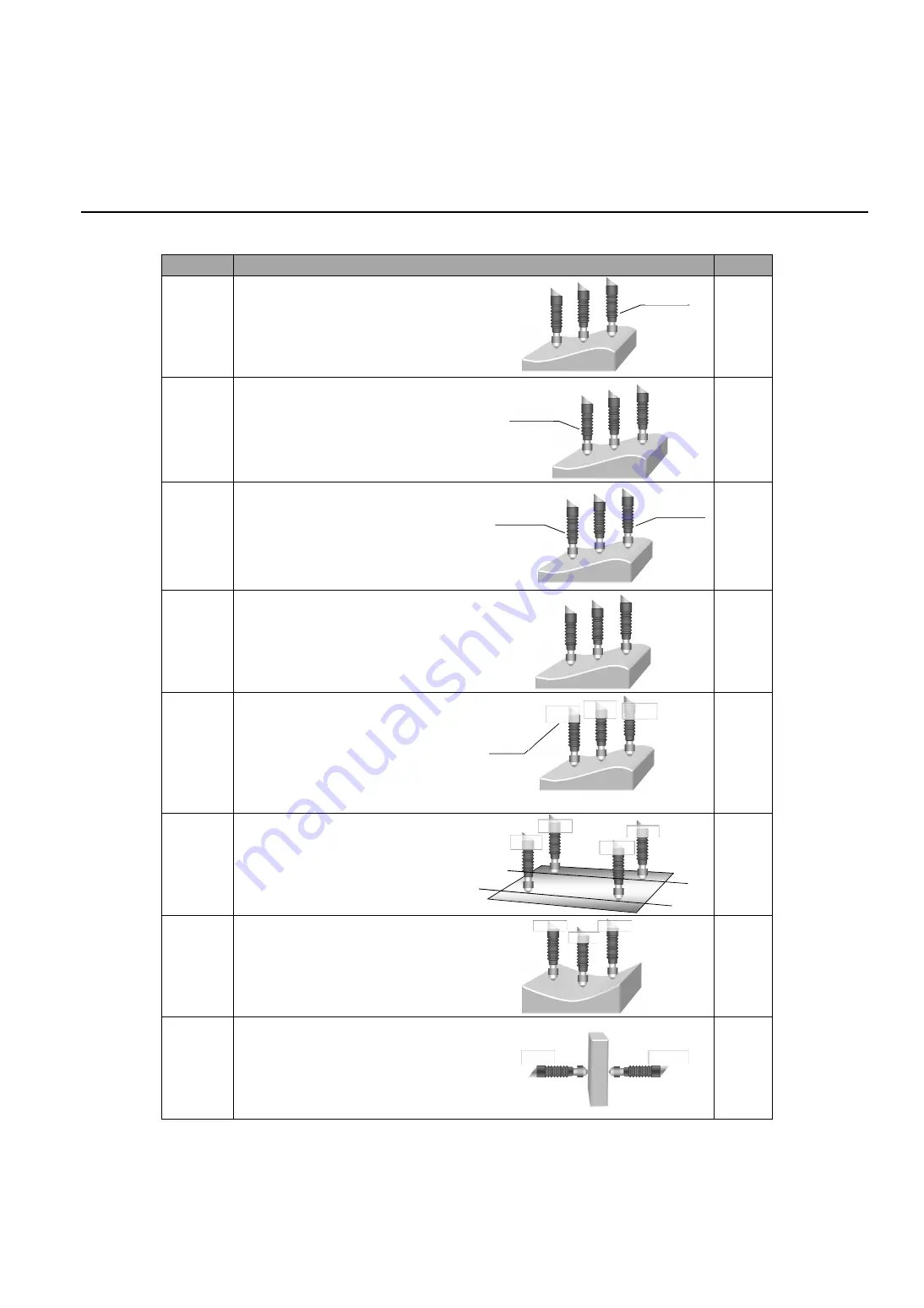

Application

Function

Remarks

Maximum

value

(MAX)

The calculation value is the maximum value

of the measurements from all the connected

controllers.

[Calculation value] = [Maximum value]

One or

more

units

Minimum

value

(MIN)

The calculation value is the minimum value of

the measurements from all the connected

controllers.

[Calculation value] = [Minimum value]

One or

more

units

Flatness

(FLAT)

The calculation value is the difference

between the maximum and minimum values of

the measurements from all the connected

controllers.

[Calculation value] = [Maximum value] −

[Minimum value]

One or

more

units

Average

(AVERAG)

The calculation value is obtained by dividing the

sum of the measurements from all the

connected controllers by the number of units.

[Calculation value] = ([Master] + [Slave 1] + ... +

[Slave n]) / (1 + n)

One or

more

units

Difference

from

standard

(STAND)

Calculations are performed on the

measurement value from the master and that

from each connected slave.

Each calculation value is obtained by

subtracting the master unit measurement

value from that from each slave unit. Each

slave unit outputs a calculation value.

[Calculation value] = [Slave n] − [Master]

One or

more

units

Torsion

(TORSIN)

Measurements from four points are used to

calculate level of torsion. The calculation

value is the result of this calculation.

[Calculation value] = ([Master] − [Slave 1]) −

([Slave 2] − [Slave 3])

Three

units

Curvature

(CURVEA)

Measurements from three points are used to

calculate level of curvature. The calculation

value is the result of this calculation.

[Calculation value] = ([Master] + [Slave 2]) / 2 −

[Slave 1]

Two

units

Thickness

(THICK)

The object to be measured is placed between the

sensor heads of the master and slave units, and the

measurements obtained from these are summed to

give the calculation value.

[Calculation value] = [Master] + [Slave 1]

One unit

■

Master

Slave 2

Slave 1

Slave 3

Maximum

value

Minimum

value

Minimum

value

Maximum

value

Master

Reference

Slave 1

Slave 2

Master

Slave 1

Slave 2

Master

Slave 1