3-12

Limit Command Field is filled with the value that corresponds to the limit or operation that is

to be executed, along with the Vertical or Horizontal Absolute Position to be Set Field if needed,

and then issue the appropriate CIP command from the PLC. CIP Setup is similar to the Move

Command, except that the attribute field is set to 0xc0ff and the source element field points to

the above Limit Command Buffer. The following is a list of commands that can be executed.

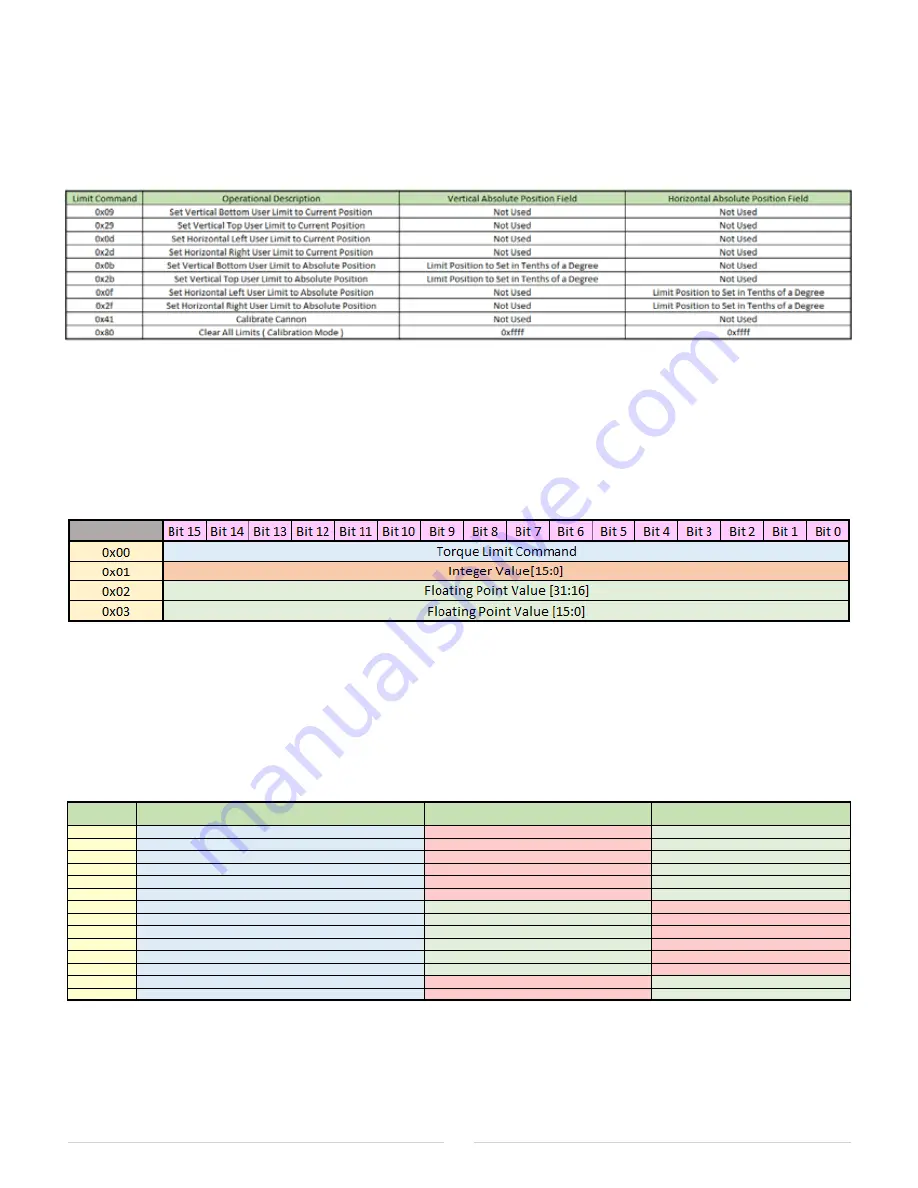

Figure 3-4.1.2 Limit Commands

3-5.1 TORQUE LIMIT COMMANDS

Torque Limit Commands are used to set operational safety limits and calibration commands

to the cannon. There are separate torque limits for the horizontal, vertical up and vertical down

movements, along with limits for vertical and horizontal detection of movement stoppage. The

structure of the PLC buffer for the Torque Limit Commands is as follows.

Figure 3-5.1.1 PLC Torque Limit Command Buffer

Torque Limit Command Field is filled with the value that corresponds to the operation that

is to be executed, along with either the 16 bit integer value or the 32 bits IEEE 754 floating

point value, and then issue the appropriate CIP command from the PLC. CIP Setup is similar

to the Move Command, except that the attribute field is set to 0xb3ff and the source element

field points to the above Torque Limit Command Buffer. The following is a list of Torque Limit

Commands that can be executed.

Torque Limit

Command

Operational Description

Integer Value Field

Floating Point Value Field

0x01

Set Vertical Up Minimum Torque ( Slow Speed Base )

Not Used

Vertical Up Minimum Torque Value

0x02

Set Vertical Up Torque Slope ( Slow to Fast Speed Mulitplier )

Not Used

Vertical Up Torque Slope

0x03

Set Vertical Down Minimum Torque ( Slow Speed Base )

Not Used

Vertical Down Minimum Torque Value

0x04

Set Vertical Up Torque Slope ( Slow to Fast Speed Mulitplier )

Not Used

Vertical Down Torque Slope

0x05

Set Horizontal Minimum Torque ( Slow Speed Base )

Not Used

Horizontal Minimum Torque Value

0x06

Set Horizontal Torque Slope ( Slow to Fast Speed Mulitplier )

Not Used

Horizontal Torque Slope

0x07

Vertical Non Movement Minimum Speed

Minimum Average Vertical Movement Speed

Not Used

0x08

Horizontal Non Movement Minimum Speed

Minimum Average Horizontal Movement Speed

Not Used

0x09

Vertical Movement Speed Margin

Vertical Speed Margin

Not Used

0x0a

Horizontal Movement Speed Margin

Horizontal Speed Margin

Not Used

0x0b

Minimum Vertical PWM for Lowest Speed Operation

Minimum Vertical PWM

Not Used

0x0c

Minimum Horizontal PWM for Lowest Speed Operation

Minimum Horizontal PWM

Not Used

0x0d

Vertical PWM Slope

Not Used

Vertical PWM Slope

0x0e

Horizontal PWM Slope

Not Used

Horizontal PWM Slope

Figure 3-5.1.2 Torque Limit Commands