LUBE-MASTER R10

13(21)

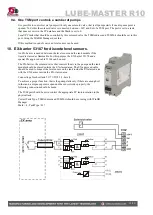

5.7. Set the type of tank (PC system).

To make it possible for the PC software to handle tank information, volumes, sensor inputs and valve output it is

necessary to define which TSM port to use, if it is a fresh oil tank or a waste oil tank, if there are any level sensors

connected and of which type if there are.

These settings are done from the PC using the LUBE-Master WinDB Manager software and are described in detail

in the LUBE-Master WinTools Manual. Below is only a short description.

To tell the system which hardware to use for each PC tank the TSM address and TSM port has to be set for all PC

tanks.

Each PC tank could share a TSM port if the same solenoid valve is used to control all pumps. This is not

recommended because of the loss of security and redundancy.

The system must be told what hardware there is and how to use it properly. This is done through the Tank Type.

Tank type is set by a string of 0 and 1 were the first position sets if it is a fresh or waste oil tank. The second position

tells if there is a discrete level sensor present or not and the third position defines if there is an analogue sensor

present or not.

Tank type is “0??” for fresh oil and “1??” for waste oil.

Tank type is “?0?” for NO discrete sensor and “?1?” for discrete sensor connected.

Tank type is “??0” for NO analogue sensor and “??1” for an analogue sensor connected.

Example:

TankType = 000, a fresh oil tank without sensors.

TankType = 010, a fresh oil tank with a discrete level sensor.

TankType = 110, a waste oil tank with a discrete level sensor.

TankType = 001, a fresh oil tank with an analogue level sensor.

TankType = 101, a waste oil tank with an analogue level sensor.

TankType = 111, a waste oil tank with both a discrete and an analogue sensor.