Programming

31

G96 S500 M03 ;

G00 X2.1 Z0.1 M08 ;

Z-1.125 (1" PART LENGTH PLUS THE TOOL WIDTH) ;

G01 X-0.05 F0.005 ;

G00 X2.1 ;

G53 X0 ;

G53 Z0 ;

G105 (BAR FEED) ;

/M99 ;

M30 ;

%

5.1.3

Example 3 - Double Push

This example demonstrates a double push on the workpiece. The program contains (2)

G105

commands. The first

G105

uses the variables values set on the Bar Feeder current

commands page. The second

G105

uses

J

and

K

values to override the variable values.

This is the preferred programming method when, for example, you need the rigidity of a

short bar for part of your operation, and then to machine the rest of the longer finished part.

The material is 2" (51 mm) diameter solid stock and the finished part is 4" (100 mm) long.

The cutoff tool is 0.125" wide. The spindle/tool clearance is 0.875". The amount of stock to

remove from the face is 0.025".

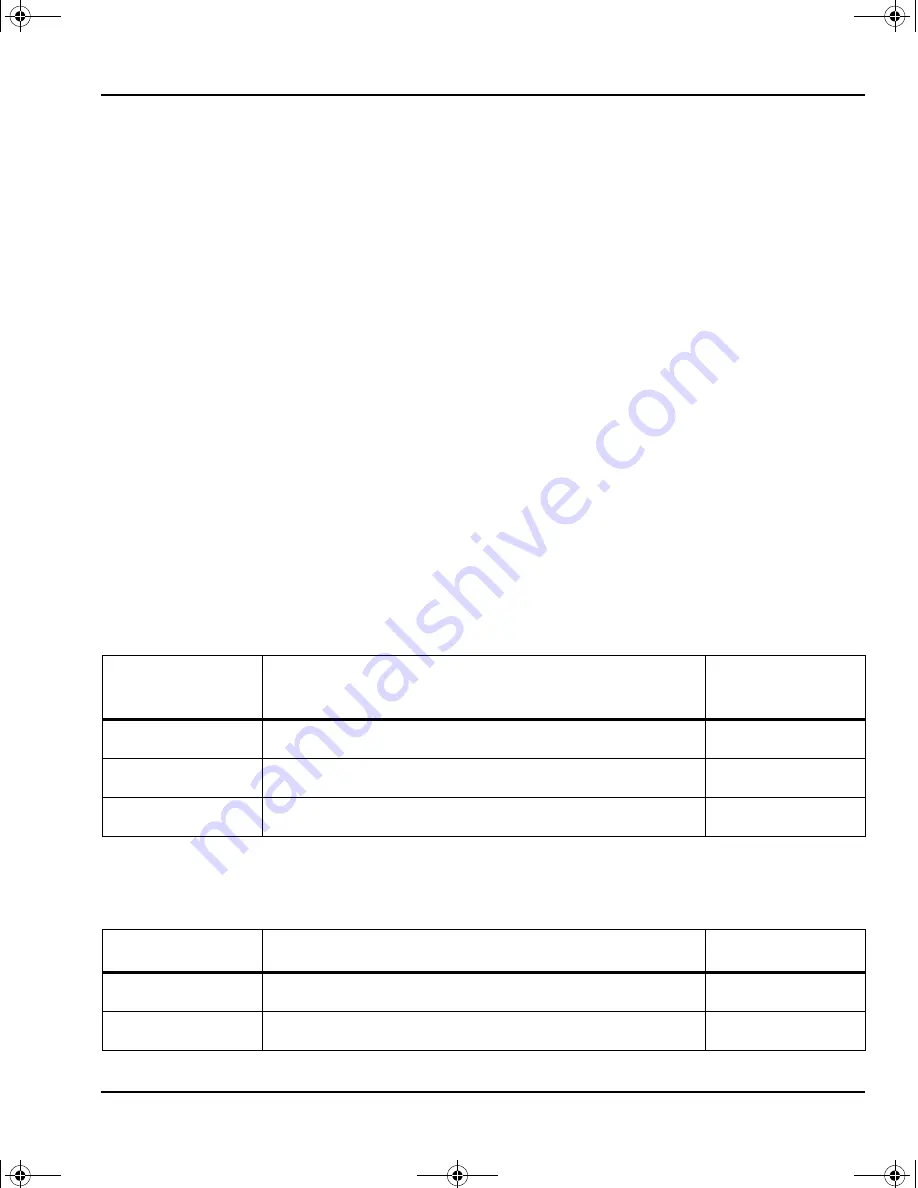

The program uses these Bar Feeder variable values. These values apply to the first

G105

command, given without address codes:

In the second

G105

command, the program uses these address codes to override the

values given in the bar feeder variables:

Variable

Number

Description

Value

#3100

Part Cutoff All Facing Allowance

1.150

#3101

Initial Push Length

2.025

#3102

Minimum Clamping Length

4.0

Address Code

Description

Value

J

Part Cutoff All Facing Allowance

3.0

K

Minimum Clamping Length

1.0

96-8913A.book Page 31 Monday, May 18, 2015 7:55 AM

Summary of Contents for Bar Feeder

Page 2: ...96 8913A book Page ii Monday May 18 2015 7 55 AM ...

Page 4: ...ii 96 8913A book Page ii Monday May 18 2015 7 55 AM ...

Page 10: ...viii 96 8913A book Page viii Monday May 18 2015 7 55 AM ...

Page 36: ...More Information Online 20 96 8913A book Page 20 Monday May 18 2015 7 55 AM ...

Page 42: ...More Information Online 26 96 8913A book Page 26 Monday May 18 2015 7 55 AM ...

Page 56: ...40 96 8913A book Page 40 Monday May 18 2015 7 55 AM ...