6. PROGRAMMING EXAMPLES

PROGRAMMING EXAMPLES

31

6 PROGRAMMING EXAMPLES

This chapter provides programming examples which control the inverter with sequence programs.

Item

Program Example

Refer to Page

6.1

Reply code definitions

List of codes checked after completion of instruction code execution

32

6.2

Reading the inverter status

Reading the inverter status from the buffer memory of the master

station

33

6.3

Setting the operation mode

Selecting the CC-Link operation mode

34

6.4

Setting the operation commands

Commanding the forward rotation and medium speed signals

35

6.5

Setting the monitoring function

Monitoring the output frequency

36

6.6

Reading a parameter value

Reading the value of Pr. 7 "acceleration time"

38

6.7

Writing a parameter value

Setting "3.0 seconds" in Pr. 7 "acceleration time"

39

6.8

Over of the Functions

"acceleration time"

Setting to 50.00Hz

40

6.9

Reading the alarm definitions

Reading the inverter alarms

42

6.10

Inverter reset

Resetting the inverter

44

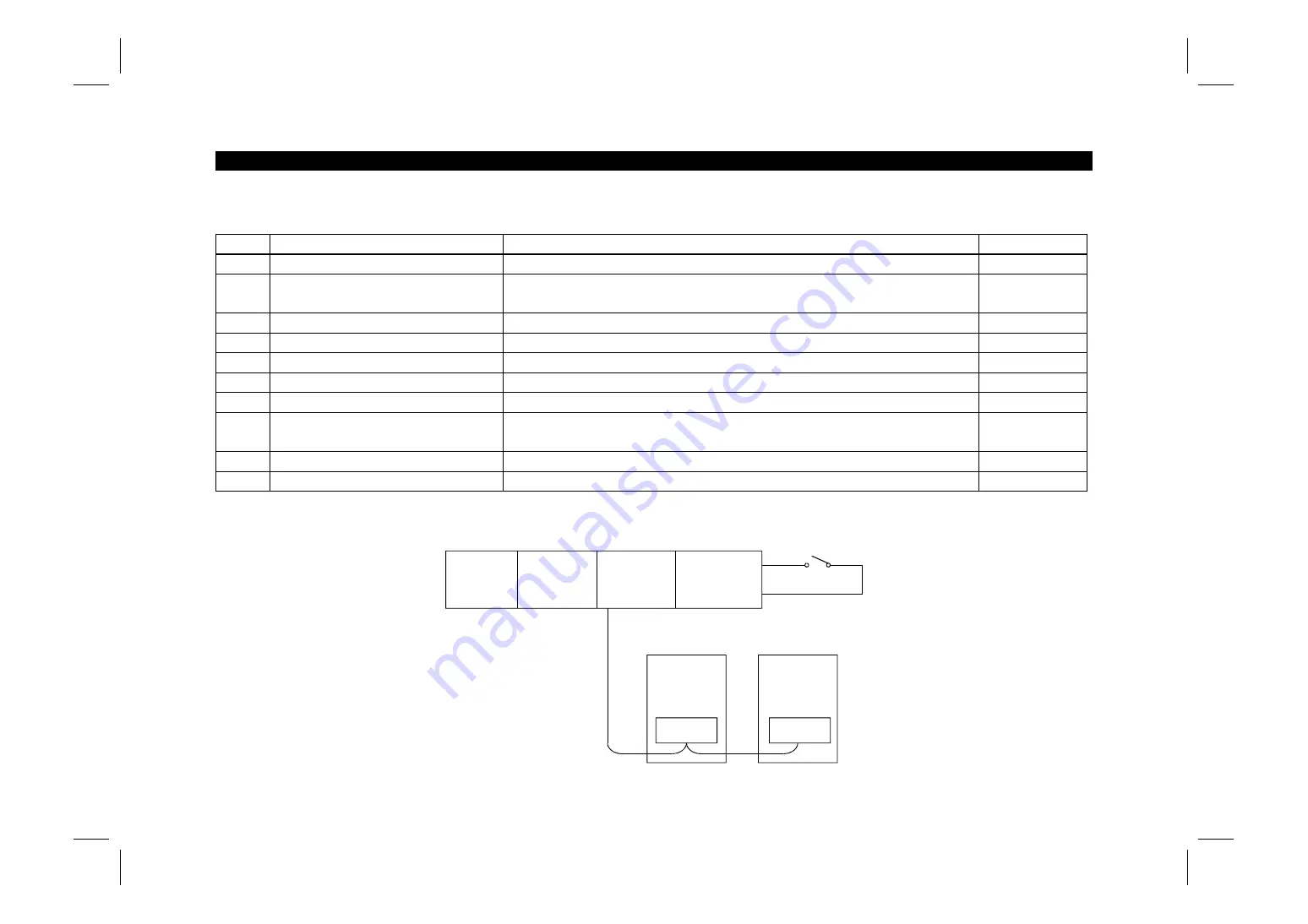

System configuration for programming example

X0020

FR-E5NC

FR-E5NC

PLC

Power

supply

Master

station

(X/Y00 to 1F)

Input

module

(X20 to X2F)

Station 1

CPU

Station 2

Inverter

(1 station

occupied)

Inverter

(1 station

occupied)