Controller functions

Page 24

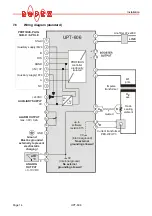

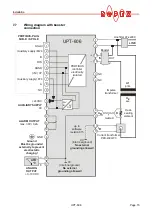

UPT-606

9.4.1

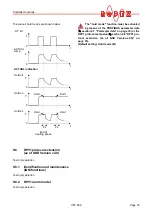

"Compact" protocol with 4-Bit

error code

The 16-bit

input data

from the PROFIBUS master to

the UPT-606 contains the set point and the control

functions and has the following structure:

The 16-bit

output data

from the UPT-606 to the PRO-

FIBUS master contains the actual value or the error

code and the status information and has the following

structure:

9.4.2

"Compact" protocol with 10-Bit

error code

The 10-Bit error codes are available on all

controllers as of software revision 100 and

supplied with GSD Version v2.0. These error codes

must be activated in the parameter data

(

section 9.7.9 "Error code format" on page 32).

The 16-bit

input data

from the PROFIBUS master to

the UPT-606 contains the set point and the control

functions and has the following structure:

The 16-bit

output data

from the UPT-606 to the PRO-

FIBUS master contains the actual value or the error

code and the status information and has the following

structure:

Control function

Spare

Set point / AC temperature

Name:

RS

ST

AC

MP

0

0

0

Bit no.:

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Error code if AL = 1

Status information

Actual value (compact) if AL = 0

Name:

AA

AG

AL

TE

TO

RA

VZ

A3

A2

A1

A0

Bit no.:

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

!

Control function

Spare

Set point / AC temperature

Name:

RS

ST

AC

MP

0

0

0

Bit no.:

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Error code if AL = 1

Status information

Actual value (compact) if AL = 0

Name:

AA

AG

AL

TE

TO

RA

VZ/A9

A8

A7

A6

A5

A4

A3

A2

A1

A0

Bit no.:

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0