5 Operation of the application

5.2 Scenario B

Speed Control with SINAMICS V90 and S7-1200 via PROFINET

Entry-ID: 109739222, V1.0, 07/2016

21

S

iem

e

n

s A

G

2

0

1

6

A

ll r

igh

ts

re

se

rv

e

d

Table 5-2-2

Output interface of FB285

Output

signal

Type

Default

Meaning

Error

BOOL

0

1 = general fault active

ErrorId

INT

0

Mode fault / block fault:

0=no fault active

1=drive fault active

2=drive switching on inhibited active

3=error of the SFB call active

PwrInhibit

BOOL

0

Switching on inhibited active

PwrInhibit=1

Busy

BOOL

0

Mode is being executed orenabled

VeloAct

REAL

0.0 [rpm]

Current velocity

dependent on scaling

factor FactRPM

DiagId

WORD

0

Extended communication error

error

during SFB call

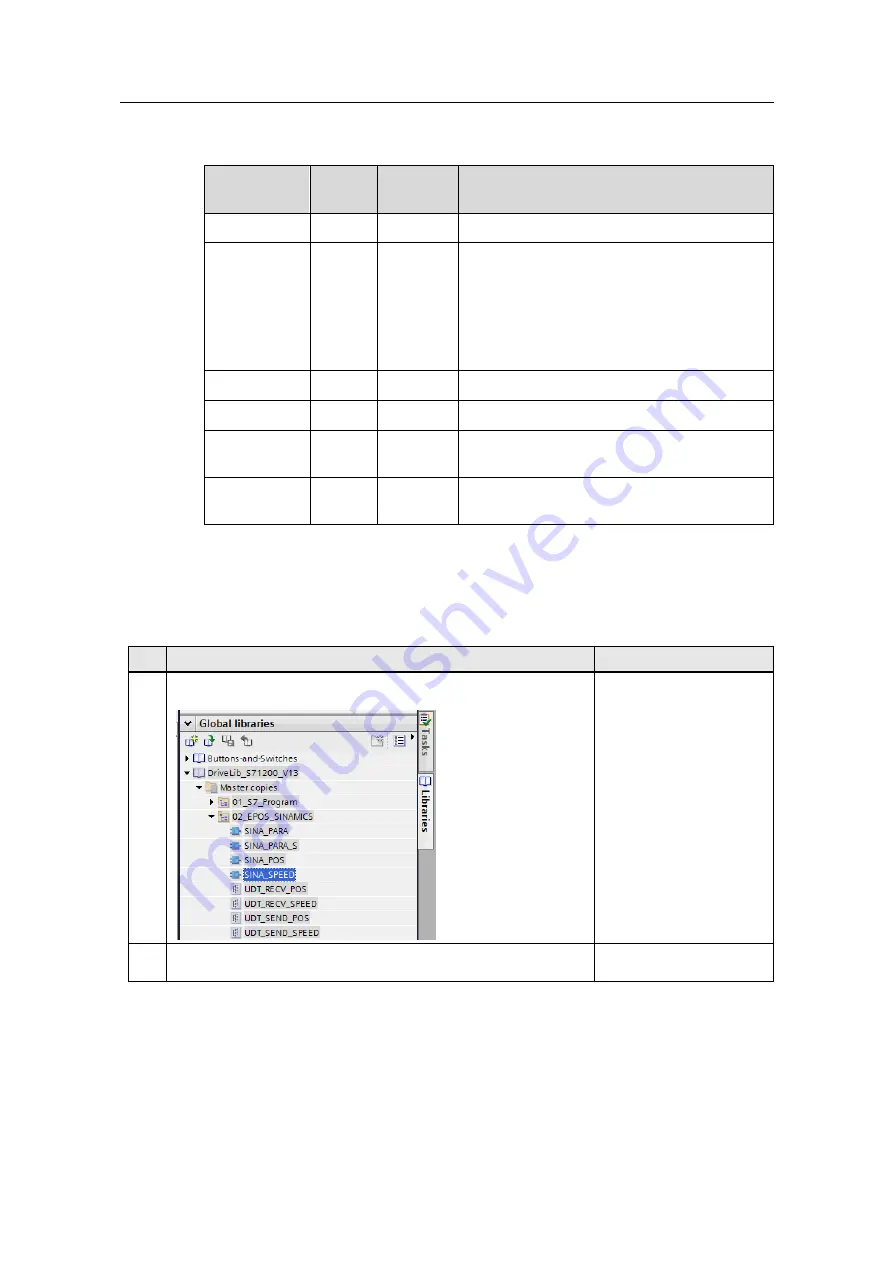

In scenario B, we will use FB285 in the library for programming and run the motor.

Table 5-2-3

Operation with FB285

No.

Action

Remarks

1. When you have installed the library, you can find it at the library view

as follows:

2. Insert or drag FB285 <SINA_SPEED> into the PLC main block and

make program as follows: