XI. Key function operation

1.

RUN/Stop mode

1

)

Under the measure mode, press and hold “R/S” key > 3 sec to enter STOP mode, SV

window will display “STOP”, main control output stops or keep the minimum output.

2

)

Under STOP mode, press and hold “R/S” key to exit STOP mode. Press “ ” key to

modify SV value.

3

)

Under STOP mode, alarm output and analog output work normally.

2. PID auto-tune operation:

1

)

Before auto-tuning, please switch off the load power, or set the meter as STOP mode.

2

)

Before auto-tuning, PV value should meet below condition: when it is PID heating

control, PV needs to be much smaller than SV; when it is PID cooling control, PV needs

to be much greater than SV.

3

)

Before auto-tuning, please set a proper alarm value or eliminate the alarm condition, in

order to prevent the auto-tuning procedure from being affected by alarm output.

4

)

Set PID type and SV value; the factory default setting is fuzzy PID.

5

)

Set as PID control, if there is OLL & OLH output limitation, please set the output to a

proper range; factory default setting is OLL=0%, OLH=100%.

6

)

Exit STOP mode, or switch on the load power, and immediately press and hold “AT ”

key to enter auto-tuning mode, then the AT indicator light is on.

7

)

The auto-tuning procedure will take some time, in order not to affect auto-tune result,

please don`t modify the parameters or power-off.

8

)

When AT light turns off, it automatically exits auto-tune mode, PID parameters will be

updated automatically, and then the meter will control automatically and precisely.

9

)

During the auto-tuning procedure, below actions will cause the termination of the

precess, press and hold “AT” key, measure beyond the scope, abnormal display, switch

to STOP mode, power-off, etc.

10

)

Note: In the occasions with output limiting operation, sometimes, even if the

auto-tuning is carried out, the best PID parameters still cannot be obtained.

11

)

Experienced users can set a proper PID parameter according to their experience.

3.PID heating and proportional cooling control operation

1

)

Set the control mode OT as 3.

2

)

PID heating control operates on OUT1; proportional cooling control operates on OUT2.

3

)

Proportional cooling control OUT2 outputs via AL1 alarm function terminals.

4

)

Please set the cooling start hystersis DB to a value greater than 5, to ensure the cooling

output will not affect the PID heating control.

5

)

Please set the cooling control cycle CP1 and the cooling proportionality coefficient PC

to the proper value.

6

)

When PV value > SV+DB value, the cooling control start to effect; the bigger value of

PV, the longer output time of OUT2

4. Auto-manual switch function

1

)

Enter common menu, set parameter A-M as “AM”.

2

)

After return back to measure control interface, press “ ” key to switch auto-manual

operation.

3

)

When it is switched to manual control, lower line LED will display output percentage:

M0~M100 (corresponding to 0%~100%), press UP key and DOWN key to modify the

output percentage.

4

)

Before the switch from manual control to auto control, in order to ensure the smooth

switch, please press Shift key to modify the SV value first.

5

)

After the meter is rebooted, the default setting is manual control and output 0%.

SET

SET

Display

LLLL/HHHH

Checking methods

Checks whether the input disconnection and whether normal of FH/ FL value,

working environment temperature and whether input signal is selected correctly.

X. Checking methods of simple fault

(

2

)

Alarm extension function table

AE1/AE2

value

0

1

2

3

4

5

Alarm handling method when

it displays HHHH/LLLL

Power on, alarm inhibition

Power on, no alarm inhibition

(

As long as the alarm condition is met, alarm

output immediately.)

Power on, alarm inhibition

(

After power on and before the PV value reaches

the SV for the first time, the alarm will not output.

After that alarm work normally)

Alarm status remains the same

Forced alarm output

Forced alarm close

Alarm status remains the same

Forced alarm output

Forced alarm close

8

7

Handling of abnormal communication:

When abnormal response, put 1 on the highest bit of function code. For example: Host request

function code 0x03,and slave response function code should be 0x83.

Error code:

0x01--- Illegal function: the function code sent from host is not supported by meter

0x02--- Illegal address: the register address designated by host beyond the address range of

meter.

0x03--- Illegal data: the written data value sent from host exceeds the corresponding data range

of meter.

Communication cycle

:

Communication cycle is the time from host request to slave response data, i.e.: communication

cycle= time of request data sslave preparation time + response delay time + response

return time, e.g.: 9600 Baud rate:communication cycle of single measured data ≥250ms.

Meter adopts Modbus RTU communication protocol, RS485 half duplex communication.

Read function code 0x03, write function code 0x10 or 0x06. Adopt 16 digit CRC check, the

meter does not return for error check. Factory default setting: slave address 1, baud rate 9600,

no check, 8 digits data bit, 1 digit stop bit, data type is 16 digits signed (unsigned) int.

Data frame format:

1. Read register

For example:Host reads integer SV(set value 200

)

The address code of SV is 0x2000, because SV is integer(2 dyte), seizes 1 data register. The

memory code of decimal integer 200 is 0x00C8. Note: when reading data, should read DP

value or confirm DP menu value first to ensure the decimal point postion, after that transform

the read data to get the actual value. Conversely, it should transform the data to

corresponding ratio before writing the data in meter

XII. Communication protocol

Start bit

Data bit

1

8

1

Set in Menu PRTY

Stop bit

Check bit

XIII. Version and Revision History

2021.06.30

1st edition

A/0 version

Date

Version

Revision content

Meter

ADD

Function

code

Start

ADD

high bit

Start

ADD

low bit

Data byte

length

high bit

Data byte

length

low bit

※

CRC

code

low bit

※

CRC

code

high bit

Host request (Read multi-register)

1 2 3 4 5 6 7 8

0x01 0x03 0x20 0x00 0x00 0x01 0x8F 0xCA

Function code abnormal answer: (For example: host request ADD is 0x2011)

1

2

3

8

9

0x01 0x83 0x02 0xC0 0xF1

Meter ADD Function code

Error code

Slave abnormal answer(Read multi-register)

※

CRC code

low bit

※

CRC code

high bit

Slave normal answer(Read multi-register)

Data

low bit

Data

high bit

※

CRC code

low bit

※

CRC code

high bit

1

2

3

4

5

6

7

0x01

0x03

0x02

0x00

0xC8

0xB9

0xD2

Meter

ADD

Function

code

Data byte

length

2. Write multi-register

For example: Host use 0x10 function code write SV

(

set value 150

)

ADD code of SV is 0x2000, because SV is integer(2 dyte), seizes 1 data register. The hexadecimal

code of decimal integer 150 is 0x0096.

0x01 0x10 0x20 0x00 0x00 0x01 0x02 0x00 0x96

Meter

ADD

Function

code

Start ADD

high bit

Start ADD

low bit

Data byte

length high bit

Data byte

length low bit

※

CRC code

low bit

※

CRC code

high bit

Slave normal answer (write multi-register)

8

7

6

5

4

3

2

1

0x09

0x0A

0x01

0x00

0x00

0x20

0x10

0x01

Data

low bit

※

CRC code

low bit

※

CRC code

high bit

ADD

low bit

Data

high bit

Meter

ADD

Function

code

ADD

high bit

Data

low bit

※

CRC code

low bit

※

CRC code

high bit

ADD

low bit

Data

high bit

Meter

ADD

Function

code

ADD

high bit

Host write SV with 0x06 function

(

set value 150

)

Slave normal answer

(

write single-register

)

8

7

6

5

4

3

2

1

0x00

0x00

0x20

0x06

0x01

Host request

(

write single-register

)

8

7

6

5

4

3

2

1

0x64

0x02

0x96

0x64

0x02

0x96

0x00

0x00

0x20

0x06

0x01

Meter ADD Function code

Error code

※

CRC code low bit

※

CRC code high bit

5

4

3

2

1

0xA1

0x01

0x86

0x02

0xC3

Slave abnormal answer ( write single-register)

Meter

ADD

Function

code

Start

ADD

high bit

Start

ADD

low bit

Data byte

length

high bit

Data

high

bit

Data

low

bit

Data byte

length

low bit

Data

byte

length

1 2 3 4 5 6 7 8 9 10 11

Host request (write multi-register)

0x07

0xFC

※

CRC

code

low bit

※

CRC

code

high bit

Default 1 decimal point

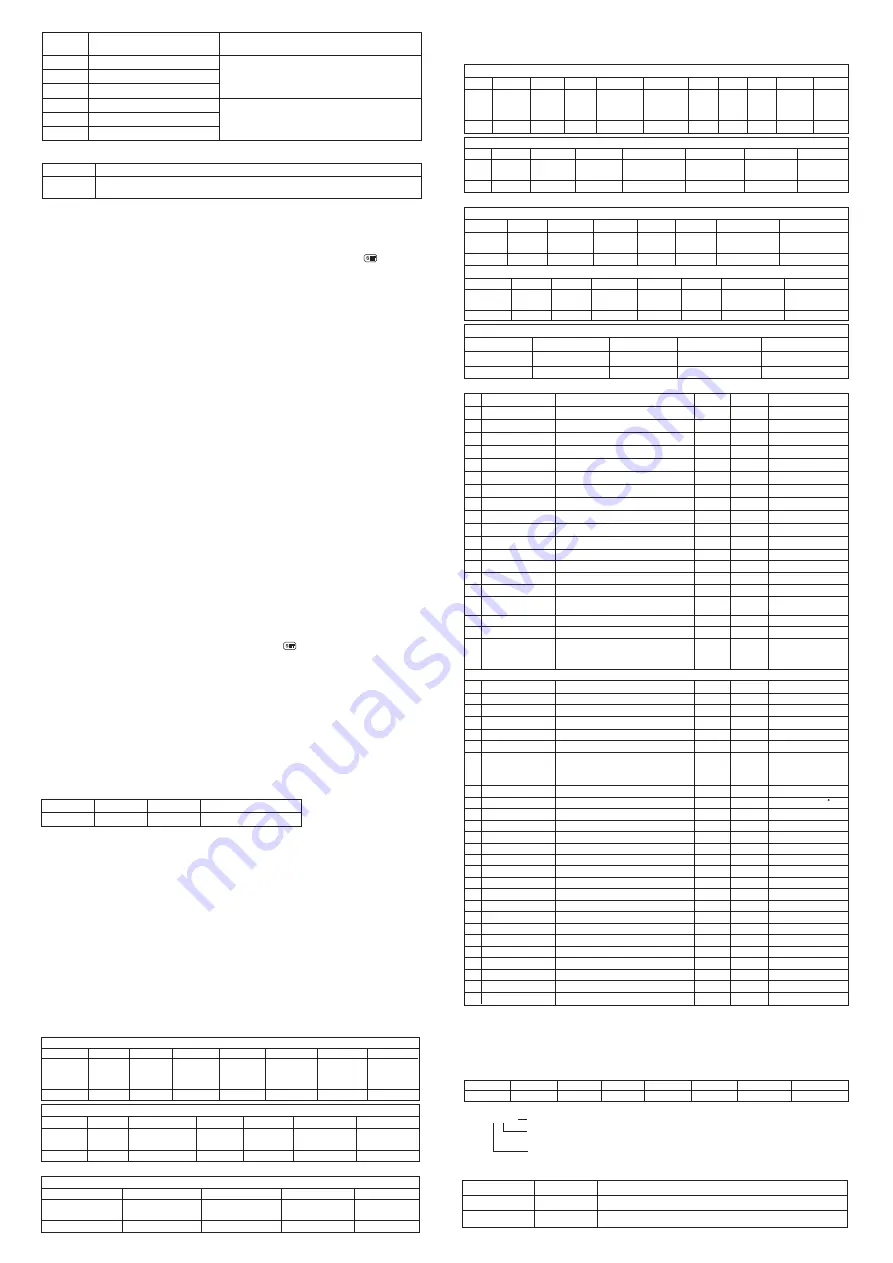

Meter parameters address mapping table

0x2000(48193)

0x2001(48194)

1

2

No. Add(Register No

①

)

Register R/W

Remark

1

1

R/W

R/W

0x2003

(48196)

4

1

R/W

0x2002

(48195)

3

1

R/W

24

25

Output mode ACT

R/W

26

RUN/STOP operation

R/W

1st alarm extended function AE1

R/W

22

23

Control mode OT

2nd alarm extended function AE2

R/W

R/W

20

21

1st alarm mode AD1

Reserve

2nd alarm mode AD2

R/W

R/W

1:RUN 2:STP

3:Run auto-tune

4:Stop auto-tune

0x2004

(48197)

0x2005

(48198)

0x2006

(48199)

0x2007

(48200)

0x2008

(48201)

0x2009

(48202)

0x200A

(48203)

5

6

7

8

9

10

11

Default 1 decimal point

Engineering work

without decimal point

1

1

1

1

1

1

1

1

1

1

1

1

1

1

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

0x200B

(48204)

0x200C

(48205)

0x200D

(48206)

0x200E

(48207)

0x200F

(48208)

0x2010

(48209)

12

13

14

15

16

17

1

1

1

R/W

R/W

R

0~100

0x2011

(48210)

18

1

1

1

1

0:Auto; 1: Manual

2:Auto-Manual

switch

0x2012

(48211)

19

Set value SV

1st alarm value AL1

Variable name

2nd alarm value AL2

1st alarm hysteresis HY1

2nd alarm hysteresis HY2

Display low limit FL

Display high limit FH

Analog output low limit BRL

Analog output high limit BRH

Control output low limit OLL

Control output high limit OLH

Heat & Cool control dead zone DB

Overshoot limit OVS

Proportional coefficient of cooling PC

Amend value PS

PV fuzzy tracking value DTR

Measured value PV

Output percentage MV

Auto-Manual switch A-M

1

R/W

R

0x2105

(48454)

0x2106

(48455)

0x2102

(48451)

0x2103

(48452)

0x2104

(48453)

0x2101

(48450)

0x2100

(48449)

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

27

28

29

30

31

32

33

34

35

36

37

Decimal pointDP

Unit display UT

Filter constants FT

Proportional coefficient P

Integral time I

Differential time D

Control speed fine-tune SPD

Heating control cycle CP

Cooling control cycle CP1

Cooling delay time PT

Optional input signal INP

25(℃)26( F)

No decimal point

No decimal point

No decimal point

No decimal point

No decimal point

No decimal point

Refer to signal table

41

42

43

44

PID arithmetic type PDC

Lock LCK

Meter name

Output state

38

39

40

Meter address ADD

Communication baud rate BAD

Comm. data transfer sequence

DTC

R

R

R

R

R

R

Note

②

Note ③

0x2107

(48456)

0x2108

(48457)

0x2109

(48458)

0x210A

(48459)

0x210B

(48460)

0x210C

(48461)

0x210D

(48462)

0x210E

(48463)

0x210F

(48464)

0x2110

(48465)

0x2111

(48466)

0x2115

(48470)

0x2116

(48471)

0x2117

(48472)

0x2118

(48473)

0x2112

(48467)

0x2113

(48468)

0x2114

(48469)

0x2119

(48474)

45

Parity Check PRTY

1

R

R

:

Read only

;

R/W

:

Read & write

D7 D6 D5 D4 D3 D2 D1 D0

AT AL2 AL1 OUT2 OUT1

STOP

HHHH

LLLL

Note

①

: The register number is the address converted to decimal plus 1 and then the register

identification code 4 is added in front; for example: the register number of the data address

0x2000 is 8192 + 1 = 8193 and then 4 is added in front, that is, the register number 48193;

Related applications can be seen, such as Siemens S7-200 PLC.

Note

②

: Measurement status indication. When the data bit is 1, it means execution, and when it

is 0, it means no execution.

Note

③

: DTC communication data transmission sequence description

Reserve

Byte transfer order: when it is 0, the sequence is 1, 2; and when it is 1, the

sequence is 2, 1

Reserve

□ □ □

DTC: