Texmate, Inc. Tel. (760) 598-9899 • www.texmate.com

Page 4

Apr-21-2016 DI_602A 320 DS (NZ313)_April 2016

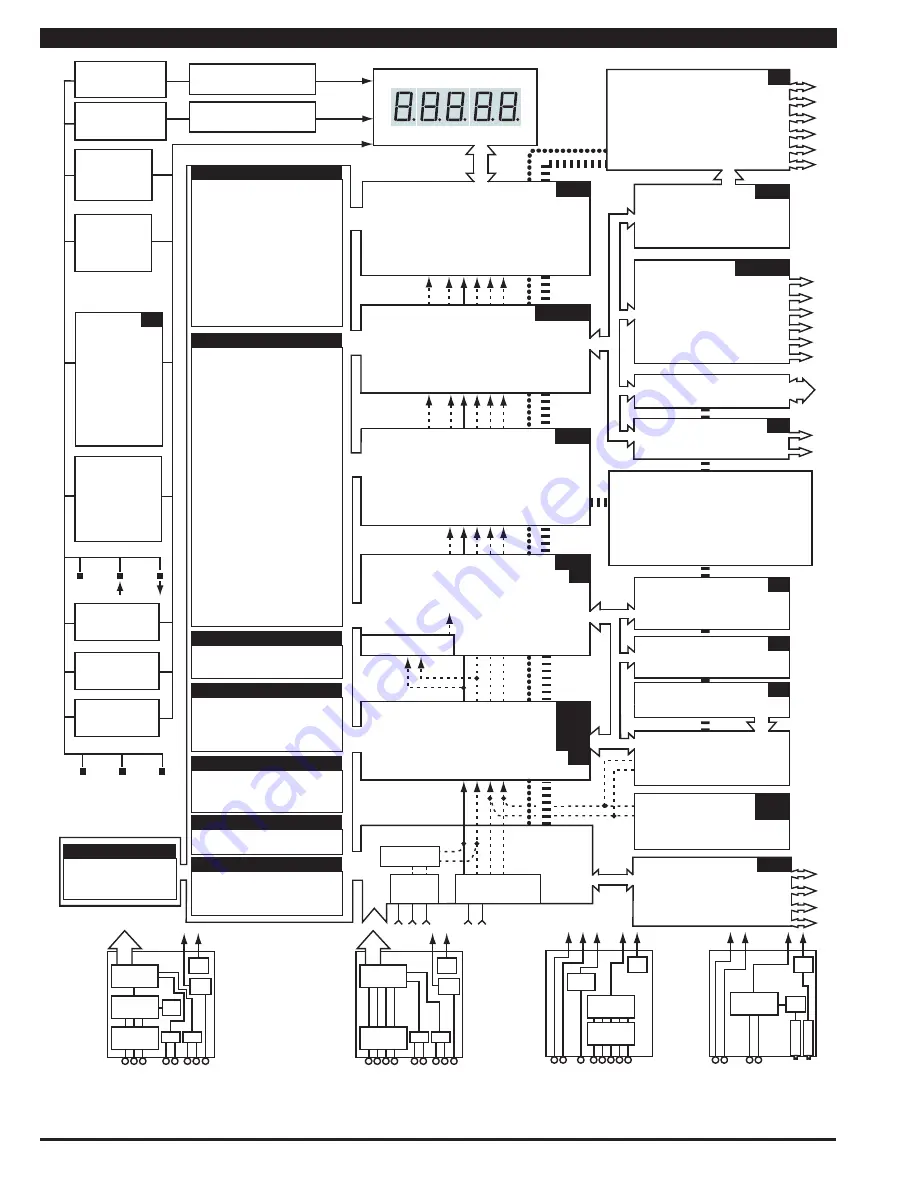

Block Diagram of the Tiger 320 Series Software and Hardware Structure

RESIDENT TIMER 1

RESIDENT TIMER 2

Runs ONLY if selected on CH3,

or CH4. Resolution 1 sec

I2C

BUS

LOGIC I/O

FROM

MODULES

Prescaler

Channel 1 & 2

17 BIT ON BOARD

DUAL SLOPE A to D

REF IN

CHANNELS

RESULT

CHANNEL

1

2

3

4

CHANNELS 1

2

1

2

3

4

1

R

R

2

3

4

1

R

D

D

2

3

4

1

R

DEFAULT

DISPLAY

CHANNEL

DEFAULT

DISPLAY

CHANNEL

2

3

4

DISPLAY FORMATTING

I2C

MICRO

Sigma Delta

A to D

16 to 24 Bit

Signal

Conditioning

REF

SSR SSR

REF

Sig

Con

SMART MODULES WITH MULTICHANNEL INPUTS,

AN ON-BOARD A TO D CONVERTER,

MICROPROCESSOR, AND TWO

SOLID STATE RELAY OUTPUTS

Signal

Conditioning

MULTI-INPUT MODULES

W/DIGITAL SCALING

MUX

REF

PULSE

Signal

Conditioning

SINGLE INPUT MODULES

WITH ANALOG SCALING

REF

ZERO

SPAN

Signal

Conditioning

REF

RAW DATA

ANALOG, DIGITAL

AND LOGIC I/O

MACRO PROCESSING

DATA LOGGING

Manual or auto, Up to 4000

samples, Date and Time

stamp, endless loop record,

Burst downloading

SERIAL COMMUNICATION

Read and write into all registers

ASCII, MODBUS,

Meter TO Meter Communication,

ETHERNET (TCP/IP), Epson Compatible

Serial Printer Driver

SETPOINTS

Up to 6 relay, SSR,

TTL or open collector.

PID, deviation, trigger, pulse,

tracking, hysteresis, latching,

timer modes, reset,

High/low/deviation activation

TOTALIZER 1

TOTALIZER 2

Two independent totalizers

Linearizing

4 Tables of 32 Points each

or 1 Table of 125 Points

Internal System Clock

Downloads from Real Time Clock

or starts from 12:00 on power up.

Can be displayed on CH3, CH4

Optional Real-time clock

with date and time stamp

Rear Pins

Hold, Test, Lock & Capture.

The Lock, Hold and Capture

pins can be reprogrammed

for use as Digital Logic I/O pins.

ANALOG OUTPUT

Voltage or current,

single or dual

PLUG IN OPTO-ISOLATED

I/O 6 IN 6 OUT OR 6 IN 16 OUT

DISPLAY DRIVE

SMART MODULES WITH AN ON BOARD

MICROPROCESSOR AND TWO SOLID STATE

RELAY OUTPUTS WITH PULSE, OR QUADRATURE

ENCODER INPUTS FOR COUNTING, FREQUENCY OR POSITION

I2C

MICRO

Signal

Conditioning

SSR SSR

REF

Sig

Con

Signal

Conditioning

Cross Channel Math

1+2, 1-2, 1x2, 1/2, 1=R

RESET

with UP/DOWN

Peak, Valley,

Tare, Totalizers

VIEW MODE

to view

selected

function values

P and UP Buttons

to enter setup

menu.

P and DOWN

Buttons to enter

setpoint menu.

PROGRAM

BUTTON

MACRO_

PROCESSING

Including

EDIT MACRO

F1_BUTTON

MACRO_

PROCESSING

F2_BUTTON

MACRO_

PROCESSING

F3_BUTTON

MACRO_

PROCESSING

ON DEMAND

FUNCTIONS

Hold down the

PROGRAM

button for 4 secs

to initiate Auto

tare, Auto

Calibration,

Manual Loader or

Input Channel

Compensation

PROGRAM LOCK

If Program lock is ON values are

displayed, but cannot be changed

SETPOINT LOCK

If Program lock is ON values are

displayed, but cannot be changed

Prog

F1

F2

F3

RESULT PROCESSING

of Cross Channel Math

Select data source for

OUTPUT PROCESSING

Select data source for: Setpoint 1, 2, 3, 4, 5, 6;

Analog output 1, 2; Data logging

Select data source for

DISPLAY PROCESSING

Select data source for:

Display 1 (Default Display Channel D), Display 2,

Display 3, Peak, Valley, Totalizer 1, Totalizer 2,

AVERAGING,

CALIBRATION (SCALE and OFFSET),

INVERSE OF INPUT, LINEARIZATION,

LOG OF INPUT (Bargraph display only)

RTD, SAMPLE RATE, SMART AUTO ZERO,

SQUARE ROOT, THERMOCOUPLES

DECIMALS, , RIGHT HAND CHARACTER, AND ROUNDING

FOR CH1, 2, 3, 4, RESULT AND DEFAULT DISPLAY

CUSTOM TEXT FOR CH1, 2, 3, 4, RESULT, PEAK, VALLEY,

TOTALIZER 1, TOTALIZER 2, SP1, SP2, SP3, SP4, SP5, SP6

DIGITAL PROCESSING

Select from R, 1, 2, 3, 4, Totalizer 1, 2, Peak,

Valley, Tare or any usable registers from 1 to 244

Select from R, 1, 2, 3, 4, Totalizer 1, 2, Peak,

Valley, Tare or any usable registers from 1 to 244

Code1

SPC_1 to 6

SPC_1 to 6

Code1

Code7

Code2

Code4

Code5

Code6

Code8

CAL

CAL

CAL

CAL

CAL

CAL

CAL

CAL

Linearization

24 bit registers in EEPROM that store

the four 32 point LIN tables.

Registers 257 to 512

OPERATING SYSTEM USE ONLY

DO NOT write to these registers, as

any alteration to their data may make

the meter inoperative.

Registers 1125 to 2048

OPERATING SYSTEM USE ONLY

DO NOT write to these registers, as

any alteration to their data may make

the meter inoperative.

Registers 4097 to 5120

Multi function, multi type Registers

that may only be accessed through

the serial port or by macros. Their

functions are detailed in the Register

Supplement.

Registers 513 to 1124

Macro Code Storage

16 bit unsigned. In Flash RAM

Registers 2049 to 4096

16 bit unsigned. May be

accessed by macros or

Serial Port.

Registers 5120 to 6144

Code9

Code5

Code6

FLASH

Result of Cross

Channel Math

AVERAGING, CALIBRATION (SCALE & OFFSET),

INVERSE of R, LOG OF R (Bargraph display only)

LINEARIZING of R,

SMART AUTO ZERO,

SQUARE ROOT of R,

SP1

SP2

SP3

SP4

SP5

SP6

Registers 1 to 244

Registers from 1 to 244 may be selected

manually as a data source for setpoint

or output processing. However only

those registers shown below contain

data applicable for use as data source.

Setpoints

6 to 11- SP1,2,3,4,5,6 value

65 to 70- SP1,2,3,4,5,6 Hysteresis,

71 to 76- delay on make SP1,2,3,4,5,6

77 to 82- delay on break SP1,2,3,4,5,6

Input Channels

18,19,20,41,42- Raw Result,CH1,2,3,4

21 to 23,43,44- Scaled Result,CH1,2,3,4

45,46- Prescaler CH1,2

Smart modules

54 to 60- Smart Output 1,2,3,4,5,6,7

Analog Outputs

83, 84 - Analog Output 1 & 2

Variables (Used with Macro Only)

85 to 94 - Variable 1 to Variable 10

Timers

95 & 96 - Timer 1, 2

Real time Clock

213 to 219 - Real Time Clock

Auto Zero Offset

227 to 231 - Auto Zero Offset for Result,

CH1, CH2, CH3 & CH4

Operating System

NOT USABLE as a data source.

15,38,47,48,52,53,61-64,123-128,140,

141,160,161,234-244

6144 REGISTERS

Registers are comprised of 8, 16 or

32 bit signed, unsigned or floating

point registers, implemented in either

Flash RAM, RAM, FeRAM, EEPROM

or NVRAM (Real time clock option).

See the Register Supplement for

detailed information on ALL registers

All registers may be accessed, and

read or written to via the serial port,

and by user developed macros.

The registers used for the operating

system should not be written into, as

modification of their data may render

the meter inoperative.

LOG BARGRAPH DISPLAY, dB DISPLAY, OCTAL.

BRIGHTNESS, ANNUNCIATORS, TREND

SCALE, OFFSET FOR CH1, 2, 3, 4 AND RESULT

A macro can access all functions and read

and write into all registers. Macro Timer1,

Macro Timer2 have 0.1 second resolution.

Macros allow a user to customize a meter

for a specific application using the Tiger 320

Development System. Macros may be locked

to prevent access by anyone.

ANALOG, DIGITAL

AND LOGIC I/O