INSTALLATION AND OPERATING INSTRUCTIONS:

GEH6000IL/GED6000IL

INSTALLATION AND OPERATING INSTRUCTIONS:

GEH6000IL/GED6000IL

18

19

EN / 2021-07-28

DDOC00212 / 0

EN / 2021-07-22

DDOC00212 / 0

Zimmer GmbH

•

Am Glockenloch 2

•

77866 Rheinau, Germany

•

+49 7844 9138 0

•

www.zimmer-group.com

Zimmer GmbH

•

Am Glockenloch 2

•

77866 Rheinau, Germany

•

+49 7844 9138 0

•

www.zimmer-group.com

11 Commissioning

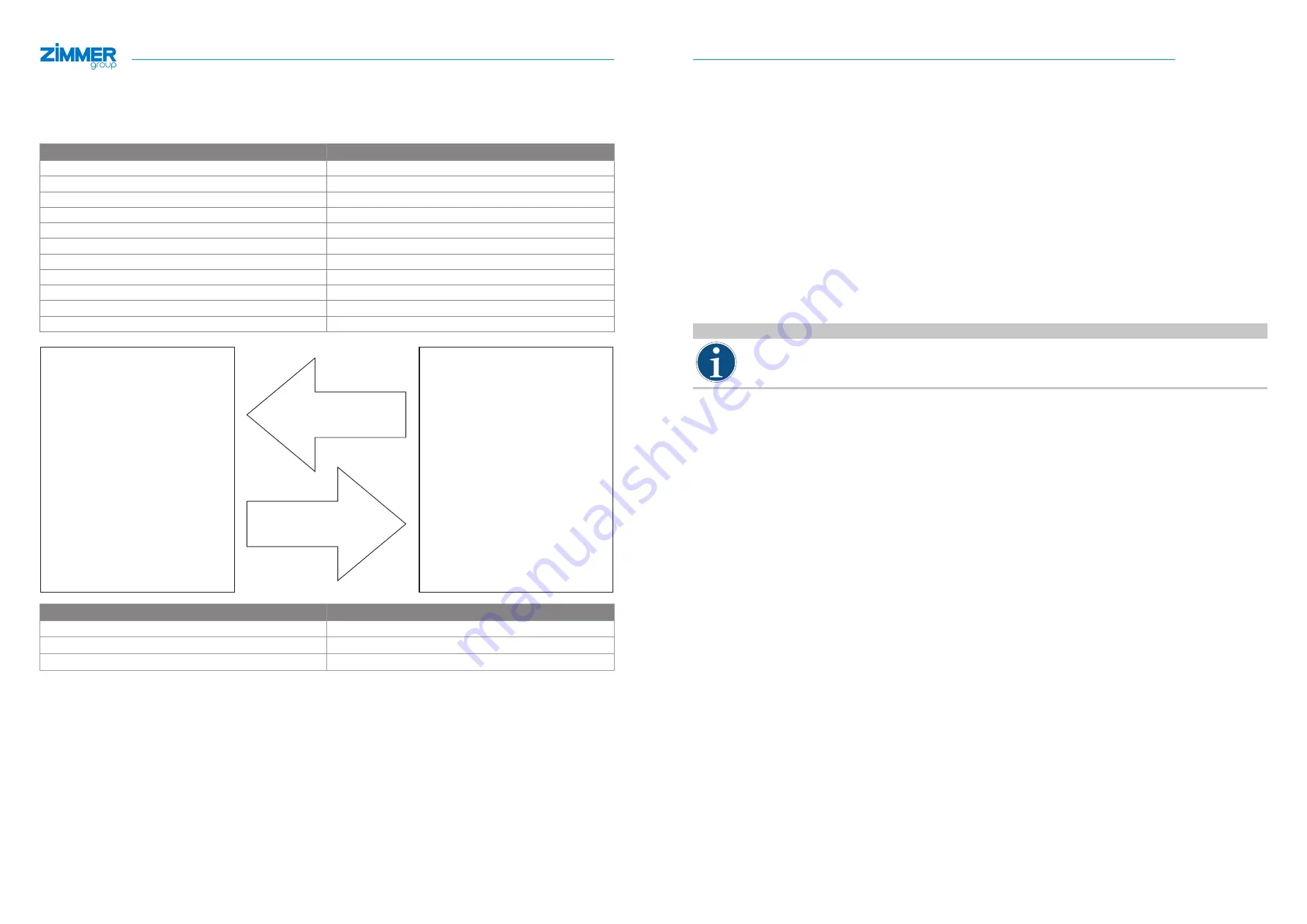

11.1 Process data

The inputs and outputs are designated from the perspective of the product.

Name

Data type

ControlWord

UINT16

DeviceMode

UINT8

WorkpieceNo

UINT8

Reserve

UINT8

PositionTolerance

UINT8

GripForce

UINT8

DriveVelocity

UINT8

BasePosition

UINT16

ShiftPosition

UINT16

TeachPosition

UINT16

WorkPosition

UINT16

Control system

Gripper

Input

Output

Name

Data type

StatusWord

UINT16

Diagnosis

UINT16

ActualPosition

UINT16

11.2 IODD import

►

Import the IODD (device description) into the control system.

►

Go to our website.

►

Select the desired product.

►

Download the corresponding .zip file via the Download IODD link.

Ö

You will need the .zip file for import into the control system.

Ö

As soon as the hardware configuration is complete and the IO-Link connection to the product is established, data will be

displayed in the process input data.

Ö

Some control systems demand a byte swap to bring this process data into a logical sequence.

►

Look at bit 6 (GripperPLCActive) in the StatusWord to determine whether a byte swap is necessary.

►

Determine whether bit 6 is active in the first or second byte of the StatusWord.

Ö

Bit 6 is active in the first byte: The bytes already have the correct sequence.

►

Continue with the commissioning.

Ö

Bit 6 is active in the second byte.

►

Apply a byte swap, see the section “StatusWord”.

INFORMATION

The product is controlled via IO-Link by means of the cyclical process data as well as the acyclic service data with

a cycle time of 10 ms.

►

It is mandatory to verify the process data.

11.3 Handshake data transfer method

The handshake method makes it possible to transfer the process data about the product. All process data described in the

following sections must be transferred with the handshake.

►

Send the ControlWord = 0x0001 to the product.

Ö

The data transfer was started.

►

Check the response of the product by using Statusbit 12 = TRUE (data transfer OK).

►

Send the ControlWord = 0x0000 to stop the data transfer.

Ö

The data transmission is complete when the product sends back Statusbit 12 = DataTransferOK = FALSE.

Ö

The sent process data of the IO-Link master is now consistent with the process data used in the product.