Program with the MODBUS Protocol

248083447-1 Rev 1

6-7

Enable Alarming for a Channel

Alarm and threshold registers are independent of each other. Any one

register’s settings will not affect the others and any channel alarms may

be enabled or disabled as the user requires. For example, to enable

alarming on just the first particle channel as shown in Table 6-7, the

user would enable Bit 1 by writing the value of ’3’ to register 43010. To

disable alarming on the first channel and enable alarming on the second

channel, write a ’1’ to register 43010 and a ’3’ to register 43012. To

enable all alarms, write a ’3’ to each of the registers 43010 and 43012.

To disable alarming completely, write a ’1’ to the enabled register or

registers (43010, 43012, 43014 or 43016).

Use the Threshold registers to set the alarm threshold value. This is

described in the next section.

Threshold Setup Registers

Threshold data is stored in the input registers in the 45xxx series which

are read/write. All threshold data items are 4 bytes long and are stored

across 2 registers. Byte and word ordering is big-endian.

For particle channels, the threshold value is a 32-bit unsigned integer.

If the data value exceeds the threshold value and the alarm is enabled

for that channel, the threshold flag in the Data Status register (30007-

30008, bit 4) is set.

The Data Status flag is set if any of the channels have a threshold

exceeded state as true.

Note:

The

Apex

Remote

comes standard with 2

particle channels.

The threshold registers (45xxx series) shown in Table 6-8, run in

parallel with the data registers (30xxx series). For example, data

register 30010’s corresponding threshold register would be 45010. Data

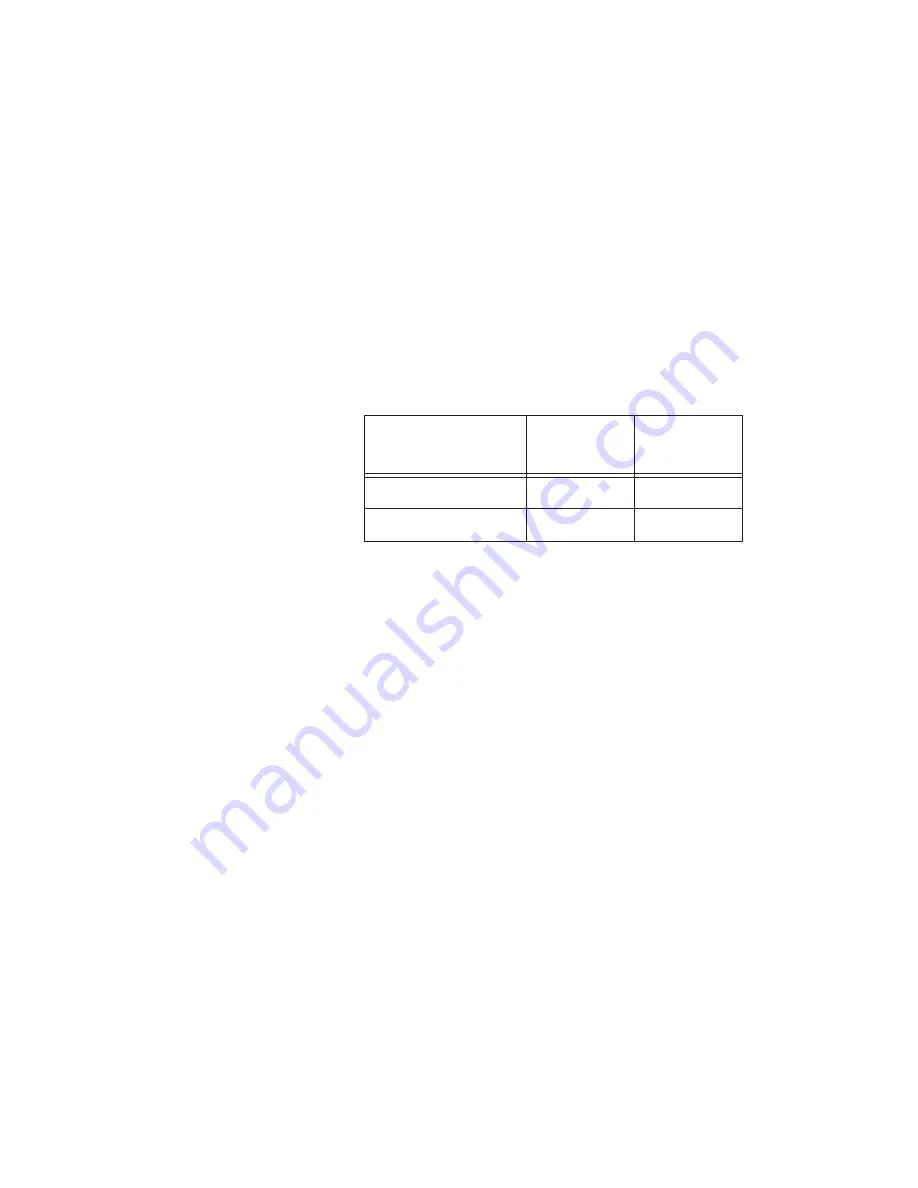

Table 6-7 Example of Alarming on Channel 2

Registers

Particle

Channel

Bit 1

Enabled

43009 - 43010

1

0

43011 - 43012

2

1

Summary of Contents for ApexR02

Page 1: ......

Page 2: ...00 ...

Page 3: ...Lighthouse Worldwide Solutions ApexRemote Airborne Particle Counter Operating Manual ...

Page 6: ......

Page 10: ...Lighthouse ApexRemote Operating Manual t iv 248083447 1 Rev 1 ...

Page 12: ...Lighthouse ApexRemote Operating Manual ii 248083447 1 Rev 1 ...

Page 22: ...Lighthouse ApexRemote Operating Manual 2 8 248083447 1 Rev 1 ...

Page 32: ...Lighthouse ApexRemote Operating Manual 3 10 248083447 1 Rev 1 ...

Page 76: ...Lighthouse ApexRemote Operating Manual A 18 248083447 1 Rev 1 ...

Page 78: ...Lighthouse ApexRemote Operating Manual B 2 248083447 1 Rev 1 ...

Page 83: ...00 ...

Page 84: ......