9

SC100/200 Series Function Block Application Manual EM-6460-C

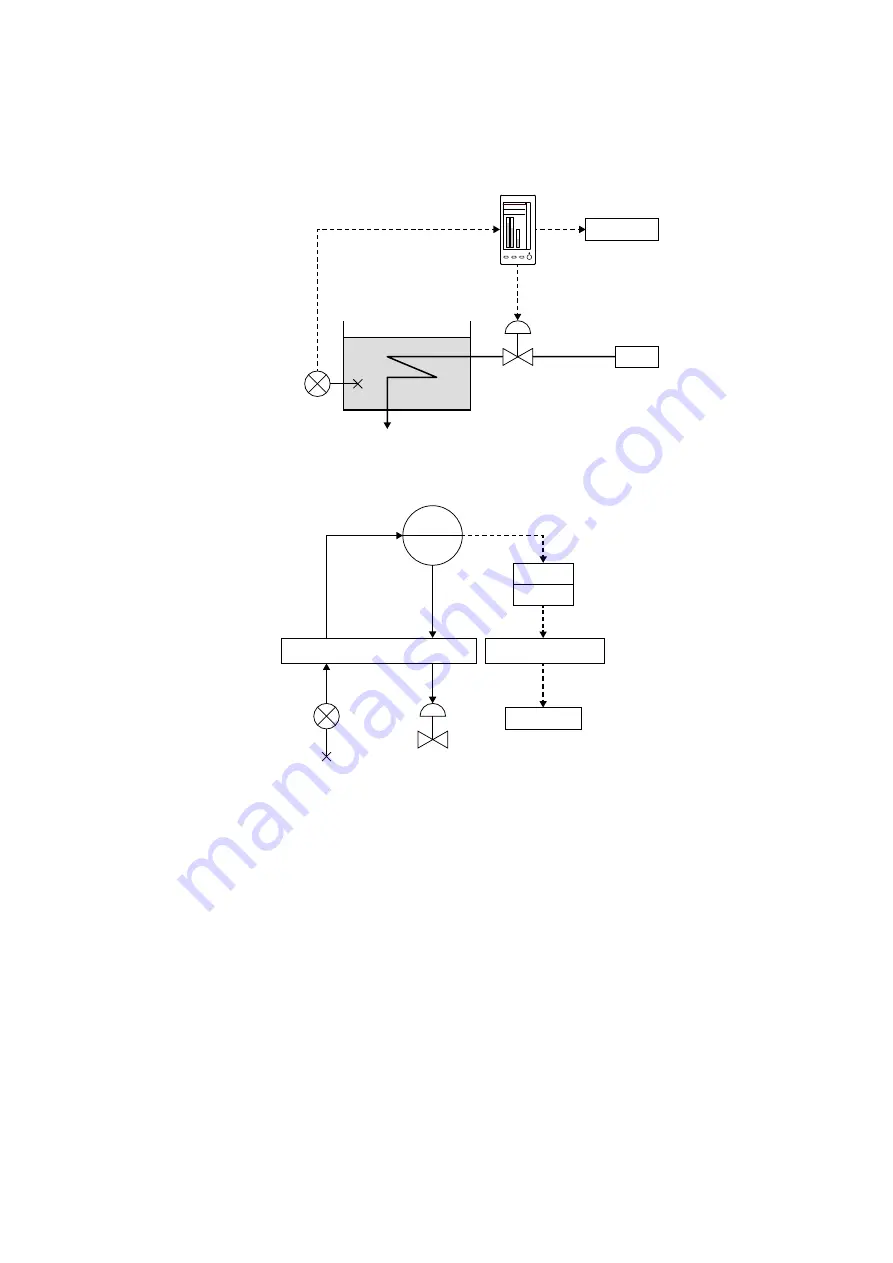

1.4 CODING PRINCIPLE

A temperature control loop with one PID control block is given as an example to explain how to proceed in coding.

(1) Determining necessary function blocks

• Basic PID is used for control function.

• High temperature limit is supplied to activate an alarm at DO terminal.

(2) Control Block

• Register Basic PID to Group 02 (or Group 03).

• Specify PV input from the SCxxx Extension Field Terminal 1 (Group 04).

• Set temperature range to 0.0-80.0°C, with ITEM 82 (upper range) set to ‘800,’ ITEM 83 (lower range) set to ‘0’

and ITEM 84 (decimal point position) set to ‘1.’

• Set reverse control action, with ITEM 40 set to ‘1’ so that the valve closes at MV output 4 mA.

(3) Sequential Control Block

• Register Sequential Control Block to Group 81.

• Write a command to turn on DO terminal at high alarm setpoint.

• Connect Basic PID terminal ‘01’ to trigger the alarm.

steam

annunciator

TIC (0-80°C)

control valve

(reverse action)

H

■

LOOP CONFIGURATION

annunciator

TIC

G02

H

PV

MV

MV

DO

PV

■

BLOCK DIAGRAM

G04 : Field Terminal

G05 : Field Terminal

SEQ

G81

hot water tank

temperature

sensor

Sequence

temp