P A G E 18

E a s y P I C P R O v 8 M a n u a l

C O N N E C T I V I T Y

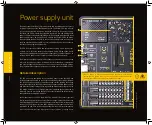

INPUT / OUTPUT section

In general, I/O pins of any MCU are internally grouped as PORTs. Such pin

grouping scheme is kept throughout the development board as well, offering

a clean and organized interface.

EXPANDED ports

There is a total of ten 8-bit ports, ranging from PORTA to PORTK (PORTI excluded).

All ten ports are EXPANDED PORTS, located at the lower left and right side of the

board

(1)

, each containing a set of eight buttons, eight LEDs, a single eight-pole

DIP switch, and a single 2x5 pin header with 2.54mm pitch. These EXPANDED

PORTS are labeled according to the MCU PORT they are routed to.

PORT buttons

Port buttons

can be used to apply the desired logic state to pins of the MCU

PORT they are routed to. These buttons are small tactile SPST switches

that

work in conjunction with a DIP switch, labeled as BUTTONS

(2)

(also labeled

as SW5 on the schematic – seperatly included). This DIP switch is located in

the BOARD SETUP section

(3)

.

BUTTONS DIP switch

This ten-position (poles), tri-state DIP switch, allows the button to apply a LOW

logic level to an MCU pin when pressed (connecting it to a reference GND), or to

apply a HIGH logic level when pressed (connecting it to the power rail). It can also

completely disconnect the button, preventing accidental button presses. To limit

the pin current and prevent the excessive inrush of currents when a button is

pressed, a protective 220

Ω

resistor is used, connected in series with the switch.

Each position of the BUTTONS DIP switch is used to determine the applied logic

level of a button press for the entire PORT, there are ten poles on this DIP switch,

allowing control of all ten groups of buttons.

UP position:

a button applies HIGH logic level to the corresponding PORT pins

(according to 8-bit labeling)

MID position:

a button is completely disconnected

LOW position:

a button applies LOW logic level to the corresponding PORT

pins (according to 8-bit labeling)

UP-PULL-DOWN DIP switch

Besides the buttons, each of the ten EXPANDED PORTS has a single eight-pole,

tristate DIP switch

(4)

, labeled as UP-PULL-DOWN (SW6 through SW15 on the

schematic – seperatly included), used to enable a pull-up or a pull-down resistor

for the specific pin, or to leave the specific pin in a floating state:

UP position:

connects a 4.7 k

Ω

resistor between the MCU power rail and the pin

associated with the particular DIP switch position (a pin is pulled-up)

MID position:

disables both pull-up and pull-down resistor connections from the

pin associated with the particular DIP switch position, leaving it in a floating state

DOWN position:

connects the 4.7 k

Ω

resistor between the GND and the pin

associated with the particular DIP switch position (a pin is pulled-down)

PORT LEDs

Each PORT contains a group of eight LEDs

(5)

, used to visually indicate a

logic state of the specific pin. The maximum current through a single LED is

limited with the 4.7k resistor. Each LED is connected to a PORT pin and it is

labeled according to the pin’s name.

LEDs on each PORT can be disabled, when they are not needed. Having a LED on

a communication line or an A/D converter input might alter expected results,

since LED represents an additional electrical load on a particular pin.

There is a DIP switch with ten positions (poles), with each pole assigned to a

specific PORT. This DIP switch is labeled as PORT LEDS

(6)

on the development

board (SW4 on the schematic). A single DIP switch position is used to disable

a group of LEDs which belong to a PORT:

ON position (up):

enables LEDs for a specific PORT, associated with the

particular DIP switch position

OFF position (down):

disables LEDs for a specific PORT, associated with the

particular DIP switch position

Summary of Contents for EasyPIC PRO v8

Page 5: ...E a s y P I C P R O v 8 M a n u a l P A G E 5...

Page 26: ...The 8th generation of hardware perfection...

Page 27: ......

Page 29: ......