Self-Balancing Robot

User Guide

3

www.terasic.com

July 12, 2018

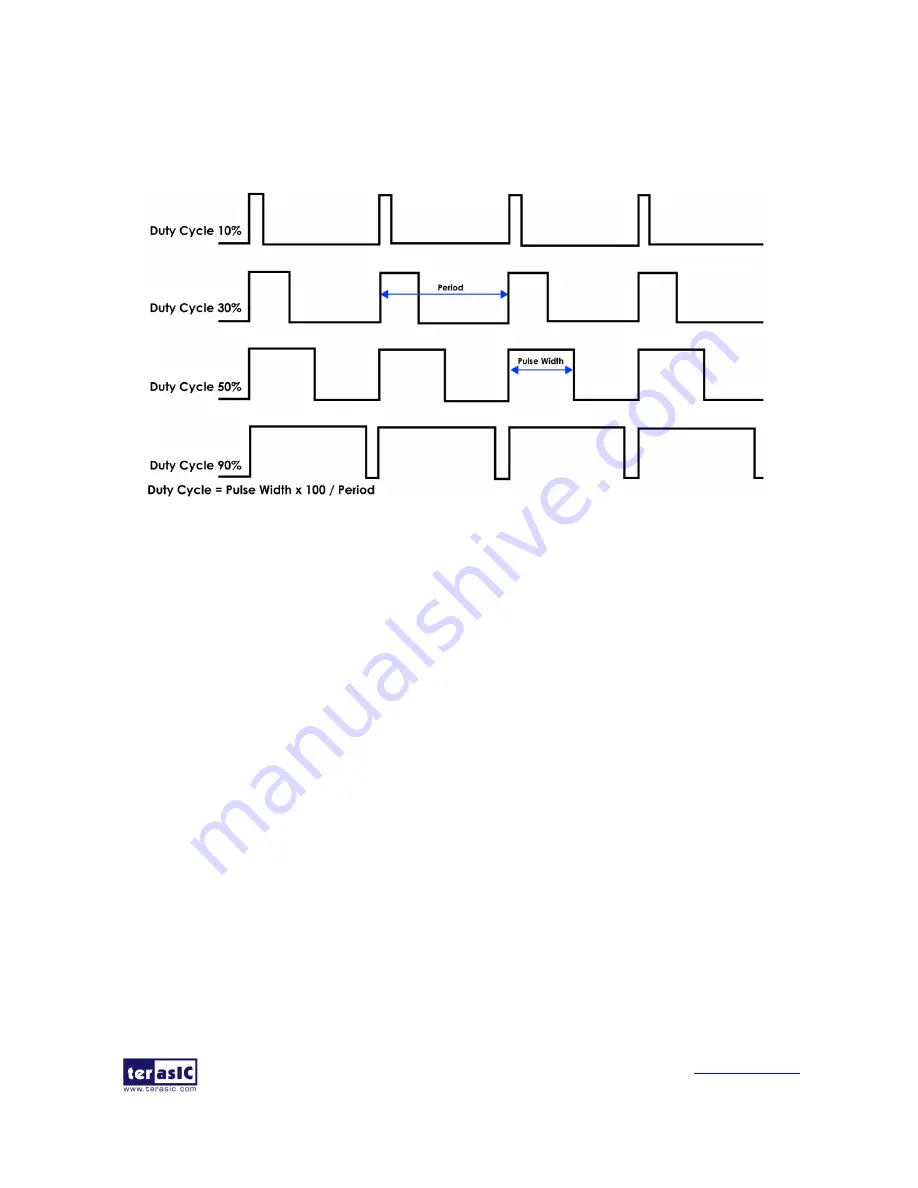

As shown in

Figure 1- 2

, the motor speed is faster while the PWM signal Duty Cycle is higher

(Which means the ratio of the high logic positive pulse duration to the total pulse period is higher).

Figure 1- 2 The diagram of different Duty Cycle

The maximum PWM frequency that TB6612FNG provides is 100KHz. For the Self-Balancing

Robot, the PWM frequency is set as 7.14KHz.

◼

◼

E

E

x

x

a

a

m

m

p

p

l

l

e

e

D

D

e

e

s

s

c

c

r

r

i

i

p

p

t

t

i

i

o

o

n

n

Motor control IP TERASIC_DC_MOTOR_PWM.v is provided in the robot demo code. In this

demo, it is packed as Qsys component and used to control the right and left motor. User can find the

TERASIC_DC_MOTOR_PWM.v

file

in

the

robot

system

CD:

Demonstrations\BAL_CAR_Nios_Code\IP\TERASIC_DC_MOTOR_PWM

⚫

⚫

I

I

P

P

S

S

y

y

m

m

b

b

o

o

l

l

Figure 1- 3

shows the symbol of TERASIC_DC_MOTOR_PWM.v and its block diagram. The

main outputs are DC_MOTOR_IN1, DC_MOTOR_IN2 and PWM, others are Avalon interface

signals. The DC_MOTOR_IN1 and DC_MOTOR_IN2 are the control signals that can control the

motor rotation direction and stopping, which has been described in previous section. PWM control

signal is responsible for controlling the motor speed.