Tiger 320 Series Programming Code Sheet

Draft Copy. Code Version V3.08a

Texmate Inc. Tel. (760) 598 9899 • www.texmate.com

1

2 February, 2005 Prog. Code Sheet V3.08a (NZ101)

PROGRAMMING CODE SHEET

T

Tiig

ge

err 3

32

20

0 S

Se

erriie

es

s

Code blanking

Code blanking blanks out all function codes

not required by the application. This means

that specific procedures such as recalibra-

tion and setpoint reprogramming can be

achieved in a few simple steps from the

front panel buttons.

To turn code blanking and macro settings

OFF, carry out the Code Blanking and

Macro Check on Page 3.

Display text editing

This function allows displayed text, such

as setpoint titles, to be edited to suit your

applications.

For example, a setpoint could be edited

to read [TNKLo] for tank level low, or

[brKoF] for brake off.

Configuration data copying

This function allows the current meter

configuration settings to be copied and

saved for later referral or for restoration.

Programming Tips

1)

Use the

button to step through the codes

of the

Main

or

Setpoint

Programming Mode.

2)

To save a

Main

Programming Mode code set-

ting and return directly to the operational dis-

play, press the

button and then the

and

buttons at the same time.

3)

To save a

Setpoint

Programming Mode set-

ting and return directly to the operational dis-

play, press the

button and then the

and

buttons at the same time.

4)

When configuring the three-digit code and

setpoint settings, pressing the

and

buttons at the same time increases the dis-

played parameter in increments of 100

counts.

P

P

P

P

P

Front panel programming

This programming code sheet (PCS) is a

quick reference document that allows you to

quickly view the meter's programming codes.

When you become familiar with the meter and

the programming code structure, the PCS can

be used in place of the user manual.

Programming via PC

Meter configuration utility program

With a serial output module installed, the

meter can be fully configured through the

meter configuration utility program

. In

addition to all application function settings,

the configuration program also provides

access to added features such as:

•

Code blanking.

•

Display text editing.

•

Configuration data copying.

•

Downloading macros to the meter.

Tamper-proof settings

All Tiger 320 Series meters have

tamper-proof lockout switches to pre-

vent users’ configuration settings from

being inadvertently changed.

Code blanking is also used (via the

PC) to blank out codes not used, mak-

ing them operator tamper-proof, but

leaving selected codes open for oper-

ator adjustment.

Macros

Texmate has a growing library of macros

to suit a wide range of standard cus-

tomer applications. Macros can be

installed in the meter, via the compiler or

configuration program, and run automat-

ically when the meter is powered up.

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

TEXMATE

Press

1

To configure the meter’s programming codes

from the front panel, the meter uses the three

right-hand side display digits. These are

known as the 1st, 2nd, and 3rd digits and can

be seen in the diagram below.

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

Operational Display

1st

Digit

2nd

Digit

3rd

Digit

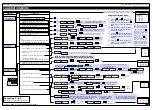

The logic diagram on Page 4 shows the code

structure of the Tiger 320 Series meter range.

Also, the difference between the E and T ver-

sion of the Tiger range is described. The dia-

grams on the following pages show the three-

digit settings available for each code.

Note:

All displays shown in this code

sheet are for a 5-digit, 7-seg-

ment LED display. Other Tiger

320 Series displays will be

slightly different.

Contents

Initial Setup Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Tiger 320 Series Code Logic Diagram . . . . . . . . . . . . . . . . .4

CALIBRATION MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

CODE 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

CODE 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

CODES 3 to 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

CODES 6 to 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CODE 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

SETPOINT PROGRAMMING MODE – SPC_1 to SPC_6 .11

Detailed Descriptions of Setpoint Functions . . . . . . . . . . . .14

Customer Code Settings – Main Programming Mode . . . . .15

Customer Code Settings – Setpoint Programming Mode . .18

Commonly Used Registers . . . . . . . . . . . . . . . . . . . . . . . . .19

User Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Note:

3-digit programming codes are

specified within square brack-

ets [XXX].

If an X appears in the descrip-

tion of a 3-digit programming

code or in a configuration pro-

cedure, this means that more

than one choice can be made,

or any number displayed in

that digit is not relevant to the

function being explained.