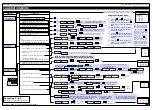

Tiger 320 Series Programming Code Sheet

Draft Copy. Code Version V3.08a

Texmate Inc. Tel. (760) 598 9899 • www.texmate.com

9

2 February, 2005 Prog. Code Sheet V3.08a (NZ101)

CODES 6 to 9

CH4 POST PROCESSING

0 Direct Display of Input (no pro-

cessing)

1 Square Root of Channel 4

2 Inverse of Channel 4

3

4 kilobits Meters

NO Linearization

32 kilobits Meters

32-point Linearization of CH4 using

Table 4

Note:

All linearization tables are set up

in the Calibration Mode [24X].

CODE 6 – CHANNEL 4 FUNCTIONS

FIRST DIGIT

SECOND DIGIT

THIRD DIGIT

FOR THERMOCOUPLE

0 Type J

1 Type K

2 Type R

3 Type S

4 Type T

5 Type B

6 Type N

7 For sensor tables other than those

listed above contact Texmate

FOR RTD TYPE (2-, 3-, 4- WIRE)

0 Resistance

1 Pt 385 100

Ω

RTD

2 Pt 392 100

Ω

RTD

3 Zn 120

Ω

RTD

4 Cu 10

Ω

RTD

MEASUREMENT TASK

0 No Function

1 Voltage, Current

2 TC

(3rd digit selects type of TC).

See Note 7

3 RTD/Resistance

(3rd digit selects type of RTD).

4 Real Time Clock and Timer

(3rd digit selects type)

5 -

6 -

7 Smart Input Module

(3rd digit selects register)

FOR SMART INPUT MODULE

0 Output Register 1

1 Output Register 2

2 Output Register 3

3 Output Register 4

4 Output Register 5

5 Output Register 6

6 Output Register 7

7 Smart Input Module

Register 3

Code Setup

RESULT PROCESSING

0 Direct Display of Result

as per processing per-

formed in 2nd and 3rd

digits

1 Square Root of Result

2 Inverse of Result

3 -

32-POINT LINEARIZATION FOR RESULT

0 No Linearization on Result

1 32-point Linearization on Result using Table 1

2 32-point Linearization on Result using Table 2.

See Note 5

3 32-point Linearization on Result using Table 3.

See Note 5

4 32-point Linearization on Result using Table 4.

See Note 5

5 125-point Linearization on Result (Tables 1 to 4 cascaded).

See Note 5

6 32-point Linearization on Result (Tables 1 to 4 selected

from the rear of the meter).

The selected table is not available if CH2, CH3, or CH4 is

operating in the analog mode. CH1 must be set to Voltage,

Current in Code 2 [X0X].

See Note 5

7 –

MATHS FUNCTIONS FOR RESULT

0 Result Register not Updated

1 pH Meter (CH1 = Tbuff, CH2 = pH)

2 Result = CH1, Setpoint 2 = CH2

3 Result = CH1 + CH2

4 Result = CH1 - CH2

5 Result = CH1 x CH2/10 000

6 Result = (CH1 x 20 000)/CH2

7 Result = CH1

CODE 7 – RESULT PROCESSING

CODE 8 – DATA LOGGING AND PRINT MODE OPTIONS

FIRST DIGIT

SECOND DIGIT

THIRD DIGIT

DATA LOG BUFFER TYPE

0 No Data Logging

1 Cyclic

Buffer

2 Linear FIFO Buffer.

3 Reset Buffer Number to 0.

Note:

Setting Code 8 to [3XX] resets the

data log buffer to 0. Once reset,

Code 8 must be set back to the

required data log buffer setting.

DATE & TIME STAMP OPTIONS

0 Printer Format – No time stamp with

print/log

1 Printer Format – Time stamp format 1 [Mth-

Day-Yr Hrs:Min:Sec] (with <CR><LF>)

2 Printer Format – Time stamp format 2 [Day-

Mth-Yr Hrs:Min:Sec] (with <CR><LF>)

3 Printer Format – Time stamp format 3

[Hrs:Min:Sec] (with <CR><LF>)

4 Spreadsheet Format – No time stamp with

print/log

5 Spreadsheet Format – Time stamp format 1

[Mth-Day-Yr Hrs:Min:Sec]

6 Spreadsheet Format – Time stamp format 2

[Day-Mth-Yr Hrs:Min:Sec]

7 Spreadsheet Format – Time stamp format 3

[Hrs:Min:Sec]

ALL ABOVE ARE REAL-TIME CLOCK OPTIONS

LOG OR PRINT TRIGGER

0 No

trigger

1 Trigger on Demand from PRO-

GRAM Button

2 Trigger on Demand from F1 Button

3 Trigger on Demand from F2 Button

4 Trigger on Demand from HOLD Pin

5 Trigger on Demand from LOCK Pin

6 -

7 -

Note:

Log and/or Print will only trigger if

enabled.

DISPLAY TEST PIN

0 Display test only

1 Reset Counter Channel 1 and total

2 at Power-up

2 Reset Counters Channel 1, 2, 3, 4,

Total 1, and Total 2 at Power-up

3 Reset Total 1, and Total 2 at Power -up

HOLD PIN

0 Display

Hold

1 Reset Channel 1

2 Reset Total 1 and Total 2

3 Reset

Total

2

4 Reset

Peak,

Valley

5 Clear

Tare

6 Set Tare

7 Unlatch (de-energize) all Setpoints

LOCK PIN

0 Key

Lock

1 Reset Channel 1

2 Reset Channel 2

3 Reset Channel 3

4 Reset Channel 4

5 Clear

Tare

6 Reset Total 1

7 Unlatch (de-energize) all Setpoints

CODE 9 – FUNCTIONS FOR DIGITAL INPUT PINS

FOR REAL-TIME CLOCK & TIMER

0 HRS:MIN:SEC

1 HRS:MIN

2 -

3 -

4 1 Second Count UP Timer

5 1 Second Count DOWN Timer

6 -

7 -

P

Press

Note 5:

If only 4 kilobits of memory is installed,

only Table 1 is available for:

•

CH1 in Code 3, 2nd digit.

•

CH2 in Code 4, 3rd digit.

•

CH3 in Code 5, 1st digit.

•

CH4 in Code 6, 1st digit.

•

RESULT in Code 7, 2nd digit.

Note:

The function of the out-

put register selected

varies according to the

input module installed.

Use the

buttons to set the

required smart input module code

(0 to 377). See installed Input

Module data sheet for code details.

2

1

3

4

5

LOCK

HOLD

TEST

COMMON

CAPTURE

TERMINAL 2 – Function Pins

Programming Tip

For digital input functions selected in

Code 9 to operate, the relevant digital

input pin must be connected to the

COMMON pin on Terminal 2 of the

controller.

The example opposite shows the

HOLD pin (pin 1) connected to the

COMMON pin (pin 4) with the selected

function activated by a switch.