Tiger 320 Series Programming Code Sheet

Draft Copy. Code Version V3.08a

Texmate Inc. Tel. (760) 598 9899 • www.texmate.com

14

2 February, 2005 Prog. Code Sheet V3.08a (NZ101)

0 Energizes ABOVE setpoint value

HYSTERESIS selected –

relay energizes AT OR ABOVE setpoint value plus hystere-

sis counts. De-energizes BELOW setpoint value minus hysteresis counts.

Note:

If hysteresis set with ZERO counts, relay energizes AT OR ABOVE the setpoint value.

DEVIATION selected –

relay energizes INSIDE deviation band (setpoint ± deviation

counts). De-energizes OUTSIDE deviation band (setpoint ± deviation counts).

PID selected –

controls ABOVE setpoint value.

1 Energizes BELOW setpoint value

HYSTERESIS selected –

relay energizes BELOW setpoint value minus hysteresis

counts. De-energizes AT OR ABOVE setpoint value plus hysteresis counts.

Note:

If hysteresis set with ZERO counts, relay energizes BELOW the setpoint value.

DEVIATION selected –

relay energized OUTSIDE deviation band (setpoint ± deviation

counts). De-energized INSIDE deviation band (setpoint ± deviation counts).

PID selected –

controls BELOW setpoint value.

2 Energizes AT OR ABOVE setpoint value with FALLING INPUT SIGNAL INITIAL

START-UP INHIBIT

HYSTERESIS selected –

relay energizes AT OR ABOVE setpoint value plus hystere-

sis counts with FALLING INPUT SIGNAL INITIAL START-UP INHIBIT. De-energizes

BELOW setpoint value minus hysteresis counts with FALLING INPUT SIGNAL INITIAL

START-UP INHIBIT.

Note:

If hysteresis set with ZERO counts, relay energizes AT OR ABOVE the setpoint value.

DEVIATION selected –

relay energizes INSIDE deviation band (setpoint ± deviation

counts) with FALLING INPUT SIGNAL INITIAL START-UP INHIBIT. De-energizes OUT-

SIDE deviation band (setpoint ± deviation counts) with FALLING INPUT SIGNAL INI-

TIAL START-UP INHIBIT.

PID selected –

controls ABOVE setpoint value.

3 Energizes BELOW setpoint value with RISING INPUT SIGNAL INITIAL START-UP

INHIBIT

HYSTERESIS selected –

relay energizes BELOW setpoint value plus hysteresis

counts with RISING INPUT SIGNAL INITIAL START-UP INHIBIT. De-energizes BELOW

setpoint value minus hysteresis counts with RISING INPUT SIGNAL INITIAL START-

UP INHIBIT.

Note:

If hysteresis set with ZERO counts, relay energizes BELOW the setpoint value.

DEVIATION selected –

relay energizes OUTSIDE deviation band (setpoint ± deviation

counts) with RISING INPUT SIGNAL INITIAL START-UP INHIBIT. De-energizes

INSIDE deviation band (setpoint ± deviation counts) with RISING INPUT SIGNAL INI-

TIAL START-UP INHIBIT.

PID selected –

controls BELOW setpoint value.

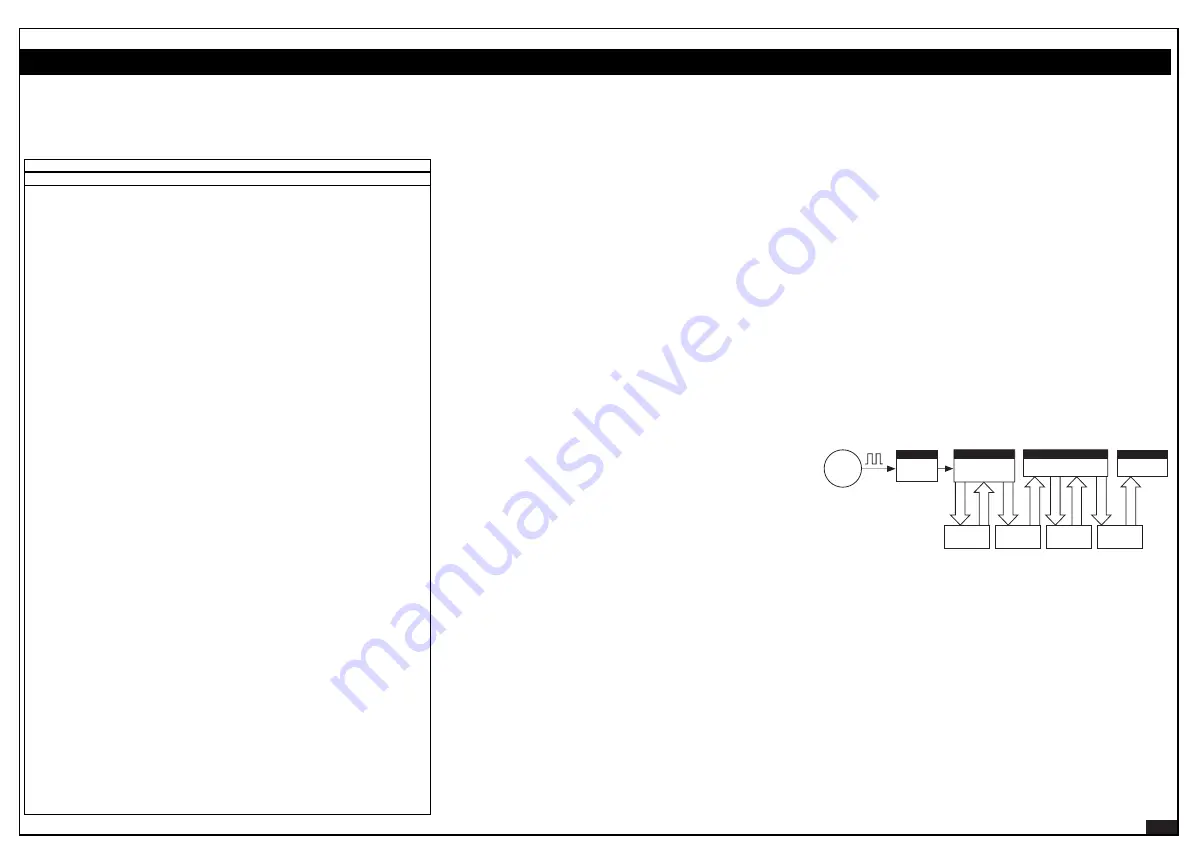

Resetting and Incrementing Using Setpoints

Setpoints may be used to reset and/or increment registers. In the

example shown opposite, 2 liter soft drink bottles are being filled

and packed 12 to a case. Using the setpoint reset and increment

feature, the number of bottles and the total number of filled cases

is easily calculated and displayed. Totalizer 1 counts from 0 to 2,

resets, and repeats. CH2 counts from 0 to 12, resets, and repeats.

Flow

Sensor

Channel 1

Flow Rate

Channel 3

Filled Cases

Totalizer 1

Flow

Channel 2

Bottles

SP5 = 2.00

Hi Setpoint

SP6 = 2.00

Hi Setpoint

SP4 = 12

Hi Setpoint

SP3 = 12

Hi Setpoint

S

O

U

R

C

E

R

E

S

E

T

R

E

S

E

T

I

N

C

R

E

M

E

N

T

I

N

C

R

E

M

E

N

T

S

O

U

R

C

E

S

O

U

R

C

E

S

O

U

R

C

E

Using Setpoints to

Increment and

Reset Registers

Detailed Descriptions of Setpoint Functions

Explanation Of Setpoint Trigger and Reset Functions

The setpoint trigger and reset functions are available on all 6 set-

points. The various parameters of these functions are described

as follows.

Trigger Type

The trigger parameter gives the option of selecting which edge of

the relay operation the reset function, print function, and data log-

ging function should activate on. It can be set to either:

•

Off

– Disables all trigger functions

•

Make

– operates on the make edge only.

•

Break

– operates on the break edge only.

•

Both

– operates on both make and break edges.

•

Level

– operates after every sample period if relay is ON.

Reset Destination

The reset destination parameter defines the target register in the

meter that is to be modified in some way when the reset trigger

conditions for this relay are met. Any Modbus register number

from 1 to 255 can be selected as a reset destination. If the [DEST]

parameter is set to [OFF], the reset function is disabled and the

Reset Mode and Reset Constant/Source selection are not dis-

played during setup. The setup sequence jumps straight to the

Print parameter.

Reset Mode

The reset mode parameter defines what type of reset effect is

required. The following different options are available.

Const

– This mode stores a user defined constant into the select-

ed destination register. In most cases this number will be zero but

it can be any number.

I-S+C

– This mode stores the current input value

I

, defined by the

setpoint source, minus the setpoint value

S

plus a user defined

constant

C

. It would normally be used with a counting or totalizing

application where the amount of setpoint overshoot needs to be

retained after the reset function. The constant value would nor-

mally be zero but could be used to provide an offset if required.

D+C

– This mode adds the user defined constant

C

to the current

value in the selected reset destination register

D

. It can be used

to increment or decrement a register by any amount.

Reg

– This mode copies the contents of a user selectable regis-

ter into the reset destination register (see Reset Constant to select

the source register).

1st Digit in Setpoint Programming Mode

Following is a detailed description of the options available on the 1st digit of

the setpoint programming mode [SPC] settings listed on Page 11.

Relay Energize Function

FIRST DIGIT

It can be used to capture data on an event and store it in an

unused channel for display or analog output, etc.

Reset Constant

This parameter defines the constant value to be used in the

Const

,

I-S+C

,

D+C

modes as previously explained. Its default

value is zero. This parameter is not available if

Reg

is selected as

the reset mode.

Source (only available in Reg mode)

If the reset mode is set to

Reg

then the source parameter allows

you to select the number of the Modbus register in the meter to

be copied to the reset destination register.