Options

Ethernet/IP (Communication Option 2)

59

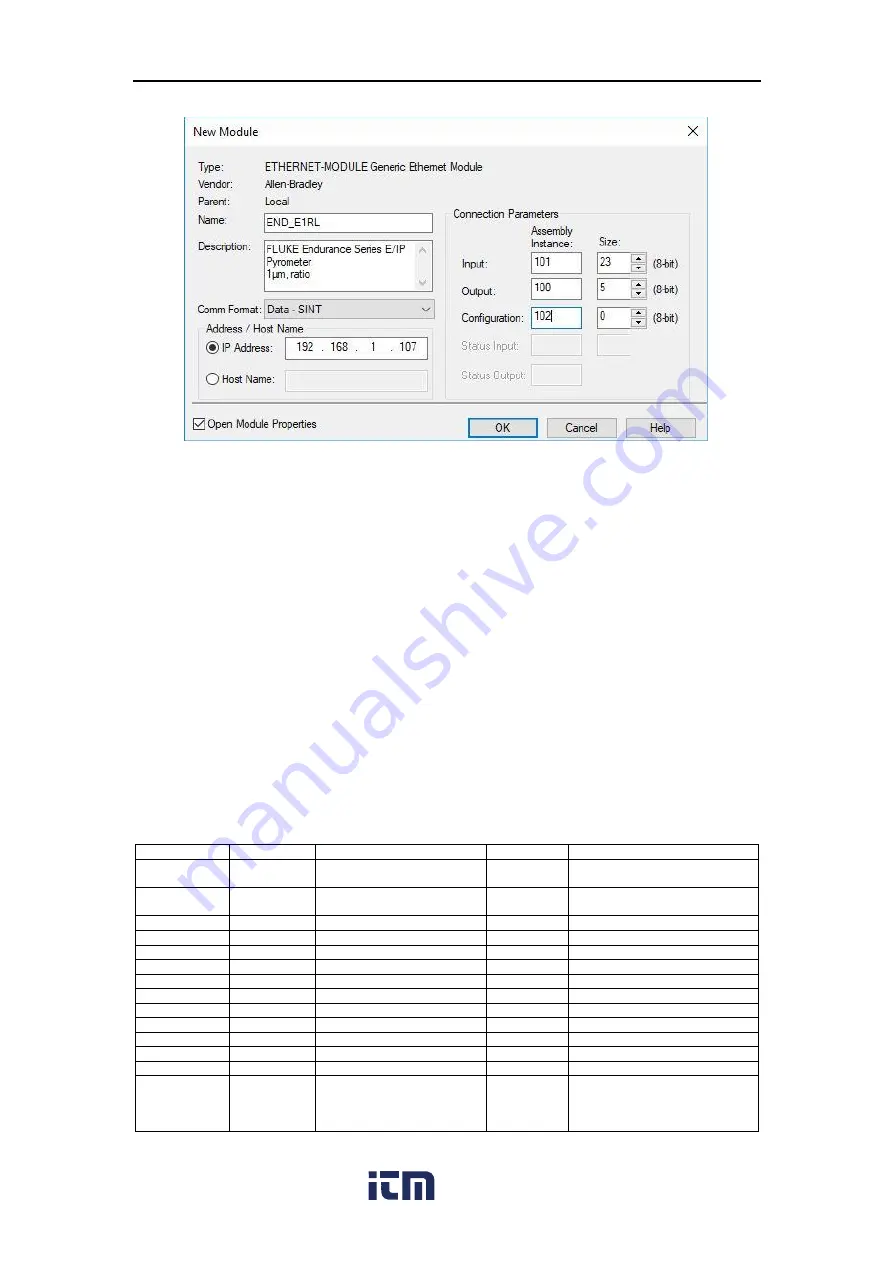

Figure 42: Device Settings via Manual Configuration

8.8.3. Parameter Setting

All settable parameters of an Endurance pyrometer are available in the Configuration Data.

Changing the parameters this way can only happen upon device initialization, i.e. when

downloading the program to the PLC (default values are sent if no changes have been made).

Once the parameter setting has been performed, the I/O device is ready to send cyclic

productive data. While certain pyrometer characteristics are parameterizable only during the

configuration, others can also be set in the data exchange mode using Output Data. The tables

below contain all the parametrizable characteristics and are followed by a short implementation

description.

8.8.3.1. Pyrometer Parameters, per Configuration Data

The parameters included in the Configuration Data are accessible through Controller Tags in

the Rockwell PLC programming environment. Changing them in the controller tags will first

have effect after downloading the program to the PLC. The Rockwell programming software

allows however for an easy saving of these tags so that the values can always be sent as

default upon initialization.

The configuration data length is 58 Byte.

Starting byte

Length

Name

Data type

Data value

0

1 Byte

Temperature unit

USINT

0x43 ('C')

– Celsius

0x46 ('F') - Fahrenheit

1

1 Byte

Color mode

USINT

1

– one color

2

– two color

2

4 Byte

Slope

REAL

0.85 ... 1.15

6

4 Byte

Emissivity

REAL

0.1 ... 1.1

10

4 Byte

Transmissivity

REAL

0.1 ... 1.1

14

4 Byte

Device Offset

REAL

-

200 … 200

18

4 Byte

Device Gain

REAL

0.8 ... 1.2

22

4 Byte

Average Time

REAL

0.0 ... 300.0

26

4 Byte

Peak hold Time

REAL

0.0 ... 300.0

30

4 Byte

Valley hold Time

REAL

0.0 ... 300.0

34

4 Byte

Set Point

REAL

Min. … Max. Temp.

38

4 Byte

Dead Band

REAL

1.0 ... 99.0

42

4 Byte

Decay Rate

REAL

0 ... 9999

46

1 Byte

Relay control

USINT

0 - normally open,

1 - normally closed,

2 - permanently open,

3 - permanently closed.

www.

.com

information@itm.com

1.800.561.8187