-114-

9.2 Mo Trigger (DefMoTrg, SetMoTrg, M_MoTrg)

The Mo trigger function is used to issue trigger signals when conditions are established based on

conditions defined by combining the following data with a comparison operation. The Mo trigger

status is output to status variable M_MoTrg.

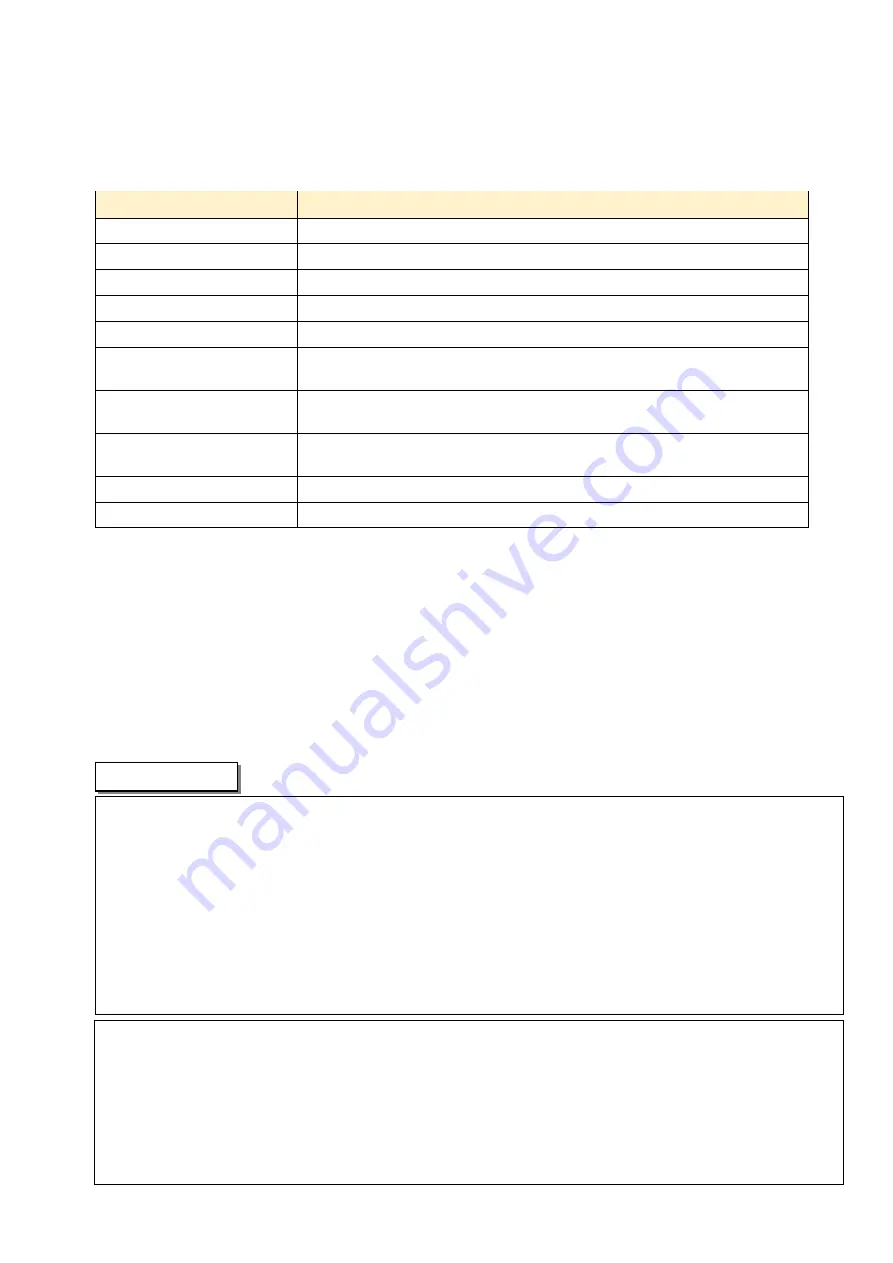

Data

Description

Each P_Curr component

Robot current position (linear data)

Each P_Fbc component

Robot FB position (linear data)

Each J_Curr component

Robot current position (joint data)

Each J_Fbc component

Robot FB position (joint data)

Each P_FsCurP component

Position command after offsetting with force control

Each P_FsCurD component

Force sensor data (values after updating offset cancel, converting tool/XYZ

coordinates)

M_FsRsltF

Force sensor data resultant force (values after updating offset cancel,

converting tool/XYZ coordinates)

M_FsRsltM

Force sensor data resultant moment (values after updating offset cancel,

converting tool/XYZ coordinates)

M_In

Input signal ON/OFF status

M_Out

Output signal ON/OFF status

By using this function, complicated trigger conditions can be specified for use with work completion

judgment/interrupt processing when abnormal work is performed (DEF ACT command), and for changing

force sense control characteristics (FsCTrg command), and so on.

To use the Mo trigger, define trigger conditions with the following procedure, and then start condition

monitoring.

<Mo trigger setting procedure flow>

(1)

Define trigger conditions with the Def MoTrg command. Up to three types of conditions can be set.

(2)

Enable the Mo trigger with the SetMoTrg command.

(3)

Perform condition branching and interrupt processing using values output to status variable M_MoTrg.

* Procedures (2) and (3) are unnecessary if using FsCTrg command.

Program example

Def MoTrg

1,

((P_Fbc.Z <= 5) AND (P_FsCurD.Z > 18))

'Define work complete conditions for Mo trigger #1.

Def Act 1, M_MoTrg(1)=1 GoTo *XOK, F

'Define Mo trigger #1 as interrupt condition.

Mvs PStart

'Move the robot above the insert position.

Set MoTrg 1

'Enable Mo trigger #1.

Fsc On, 0, 0, 1

'Enable force sense control.

Act 1=1

• • • • • •

Fsc Off

'Disable force sense control.

Act 1=0

Set MoTrg 0

'Disable Mo trigger.

End

Def MoTrg 3, (P_Fbc.Z < 100)

'Work complete conditions defined for Mo trigger 3.

Fsc On, 0, 1, 1

'Enable force sense control.

FsCTrg 3, 100, 2

'Enable Mo trigger #3 and change the control characteristics

from 1 to 2 when the trigger turns ON.

Mvs P1

• • • • • •

Fsc Off

'Disable force sense control.

End

Summary of Contents for MELFA BFP-A3614

Page 1: ...Mitsubishi Industrial Robot Robot Seminar Textbook Force Sensor Application BFP A3614 ...

Page 2: ......

Page 34: ... 23 2 F series a CR750 D controller ...

Page 35: ... 24 b CR751 D controller ...

Page 36: ... 25 c CR750 Q CR751 Q controller CPU module ...

Page 75: ... 64 MEMO Please use this page for your memo ...

Page 95: ... 84 MEMO Please use this page for your memo ...

Page 103: ... 92 MEMO Please use this page for your memo ...

Page 111: ... 100 MEMO Please use this page for your memo ...

Page 119: ... 108 MEMO Please use this page for your memo ...

Page 123: ... 112 MEMO Please use this page for your memo ...

Page 129: ... 118 MEMO Please use this page for your memo ...

Page 133: ... 122 MEMO Please use this page for your memo ...

Page 137: ... 126 MEMO Please use this page for your memo ...

Page 143: ... 132 MEMO Please use this page for your memo ...

Page 149: ... 138 MEMO Please use this page for your memo ...

Page 153: ... 142 MEMO Please use this page for your memo ...

Page 159: ... 148 MEMO Please use this page for your memo ...

Page 171: ... 160 MEMO Please use this page for your memo ...

Page 183: ... 172 MEMO Please use this page for your memo ...

Page 191: ... 180 MEMO Please use this page for your memo ...

Page 211: ......