Rev. 02-21 Page 29

USER MANUAL

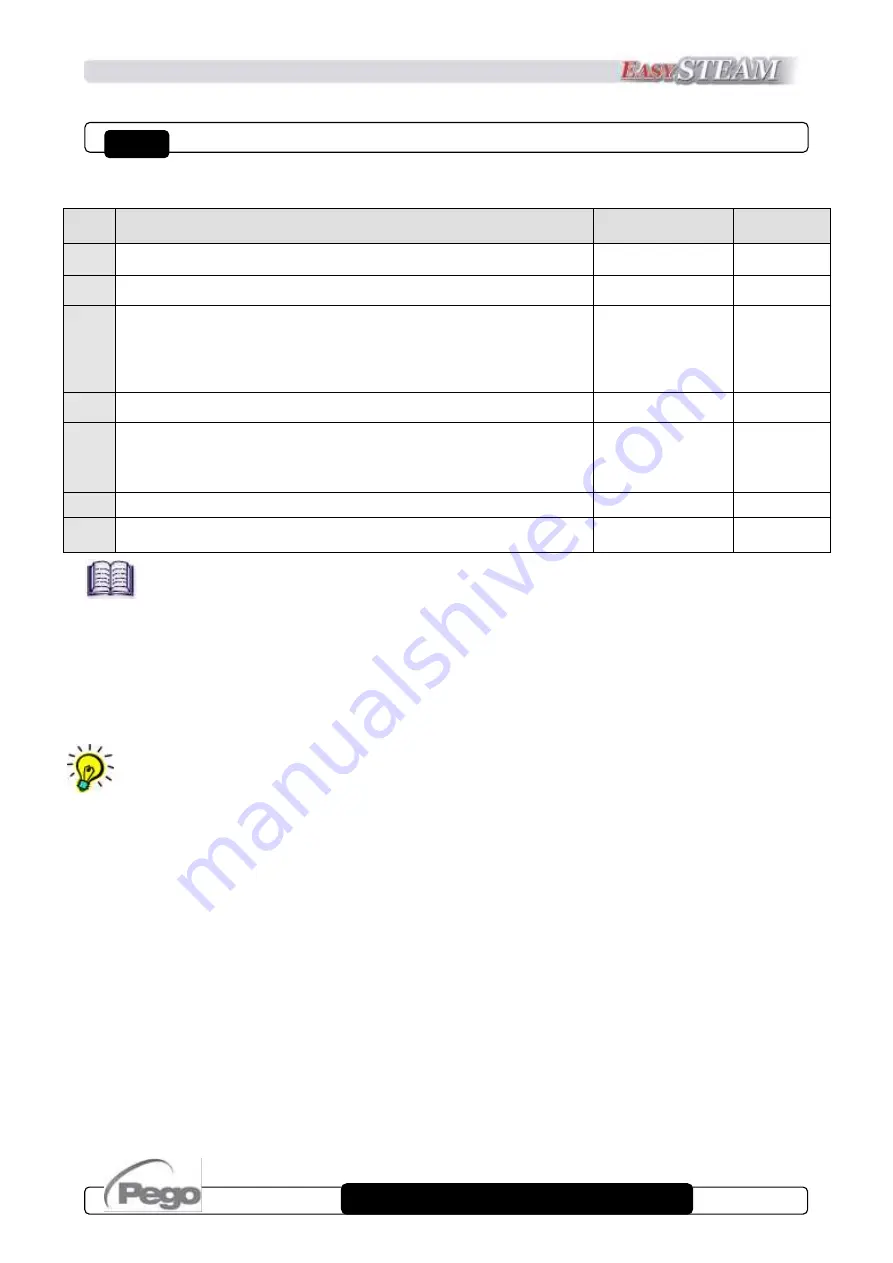

1ST LEVEL PROGRAMMING

1.

The 1st level programming enables the user to amend 2 important parameters, the Bp

proportional band and the Pr steam production percentage.

VAR.

MEANING

VALUES

DEFAULT

all models

Pr

Steam production percentage

20 ÷ 100 %

100 %

Bp

Proportional band

(not used in ON/OFF version)

1 ÷ 20 Rh%

10 %

StC

Max humidity set point in air duct.

When the set point is exceeded, the humidifier is set to off and resumes

operation when the humidity in the air duct drops below the value StC-r0

with the addition of time t1, according to the logic dictated by the 0-10V

signal or from the ambient humidity probe.

25 ÷ 99 Rh%

99%

r0

Max humidity set differential in air duct.

1 ÷ (StC – 20) Rh%

50%

r1

Temperature differential referred to set point.

For temperature values lower than set-r1, the humidifier is activated until the

set point is reached (call of heat). If S9=9, r1 is the proportional band.

(used only with S9=7 or S9=9 call of heat version)

0.2 – 10 °C

2°C

UrC

Humidity value read by the humidity probe in air duct

0-100%

read only

PrL

Percentage of steam production during operation with low conductivity

(S11=1 , Pr is ignored)

0-100%

read only

The

Bp

proportional band is the percentage value of the humidity around the set point;

within this value the humidifier works proportionally. Example: if the proportional band is

set on default value 10% (±5% set point value) and humidity is set at 50%, below 45% the

humidifier will work at 100% of steam production; above 55%, the humidifier will not produce

steam. Between 45 and 55%, the humidifier will optimally regulate steam production.

The Pr steam percentage is the value the humidifier can reach at maximum production; leaving

setting at 100%, an ES6 with 6kg/h steam production, can reach 6kg/h, if Pr setting is reduced to

50%, the humidifier can produce a maximum of 3kg/h.

The variable

Pr

is very useful in cases of low conductivity of water and to make the most of

the cylinder when it is near to replacement; for further information consult chapter 6

DIAGNOSTICS on page 36 of this manual.

The set point of maximum humidity in the duct (stC) limits the humidity in the duct.

If the humidity in the duct is higher than the value set in stC, the humidifier stops the steam

production. When the humidity returns below stC-r0, at the end of the delay time t1 (second level

variable) the steam production is resumed.

2.

To access the first level programming menu, follow the instructions below:

- Press and hold down the UP (

) and DOWN (

) keys simultaneously for a few seconds until

the first programming variable appears on the display.

- Release (

) and (

) keys.

- Use the (

) key or the (

) key to select the variable to be modified.

- After selecting the desired variable, it will be possible:

- Display its settings by pressing the SET key.

- Change its settings by holding down the SET button and pressing one of the (

) or (

) keys.

Once you have finished configuring the values, press the keys (

) and (

) for a few seconds to

exit the menu and keep them pressed until the magnitudes displayed before entry into programming

reappears, e.g. steam production or absorbed current. The memorization of the changes made to the

variables will occur automatically when exiting the configuration menu.

3.4