3

Content

1.

General Information ................................................................................................................................... 4

2.

Safety Instructions ..................................................................................................................................... 4

2.1

Basic Information .................................................................................................................................. 4

2.2

Intended & Conforming Use ................................................................................................................. 5

2.3

Nonconforming Use .............................................................................................................................. 5

2.4

Laser Classification ............................................................................................................................... 5

2.5

Electric Supply ...................................................................................................................................... 5

2.6

Important Operating Advice .................................................................................................................. 6

3.

Technical Data

............................................................................................................................................ 6

3.1

Scope of delivery .................................................................................................................................. 6

3.2

Laser ..................................................................................................................................................... 6

3.3

Measuring Performance ....................................................................................................................... 7

3.4

Interface ................................................................................................................................................ 7

3.5

Environment & Ambient Conditions ...................................................................................................... 8

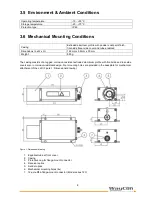

3.6

Mechanical Mounting Conditions .......................................................................................................... 8

3.7

Electrical Mounting Conditions ............................................................................................................. 9

3.8

Interface-Cable ................................................................................................................................... 10

4.

Communications Protocol

...................................................................................................................... 12

4.1

Example: Establishing Communication with Hyperterminal ............................................................... 12

4.2

Online-Help ......................................................................................................................................... 15

4.3

Commands and their functions ........................................................................................................... 16

4.3.1

DT…. distance tracking .............................................................................................................. 16

4.3.2

DS…. distance tracking 7m ........................................................................................................ 16

4.3.3

DW…. Distance tracking with cooperative target (10Hz) ........................................................... 16

4.3.4

DW…. Distance tracking with cooperative target (50Hz) ........................................................... 17

4.3.5

DF…. Distance measurement with external trigger .................................................................... 17

4.3.6

DM…distance measurement ...................................................................................................... 17

4.3.7

TP…internal temperature [°C] .................................................................................................... 17

4.3.8

SA

X

….display/set average value [1…20] ................................................................................... 17

4.3.9

SD

d

….display/set display format [d/h] ........................................................................................ 18

4.3.10 SD

x

….display/set measure time [0…25] ......................................................................................... 18

4.3.11 SFx….display/set scale factor ........................................................................................................ 18

4.3.12 SEx….display/set error mode [0/1/2] .............................................................................................. 19

4.3.13 ACx.x…display/set ALARM center (switching output) .................................................................... 19

4.3.14 AHx.x…display/set ALARM hysteresis (sign = Invertating yes/no, switching hysteresis) .............. 19

4.3.15 AWx.x…display/set ALARM width (length of switching output) ...................................................... 20

4.3.16 RBx.x…display/set distance of I

out

= 4 mA ..................................................................................... 20

4.3.17 REx.x…display/set distance of I

out

= 4 mA ..................................................................................... 20

4.3.18 RMx y.y z...... remove measurement .............................................................................................. 20

4.3.19 TDx y......display/set trigger delay [0...9999ms] trigger level [0/1] .................................................. 21

4.3.20 TMx y......display/set trigger mode [0/1] trigger level [0/1] .............................................................. 22

4.3.21 BRx......display/set baud rate [2400...38400] .................................................................................. 22

4.3.22 ASd....display/set autostart command [DT/DS/DW/DX/DF/DM/TP/LO/ID] ..................................... 23

4.3.23 OFx.x......display/set distance offset ............................................................................................... 23

4.3.24 SO......set current distance to offset (offset = - distance) ............................................................... 23

4.3.25 LO......laser on ................................................................................................................................ 23

4.3.26 LF......laser off.................................................................................................................................. 23

4.3.27 PA......display settings ..................................................................................................................... 23

4.3.28 PR......display settings .................................................................................................................... 24

5.

Operating Modes

...................................................................................................................................... 24

5.1

RS232 ................................................................................................................................................. 25

5.2

RS422 ................................................................................................................................................. 25

5.3

Digital Switching Output ...................................................................................................................... 26

5.4

Analog Output ..................................................................................................................................... 27

5.5

Trigger Input ........................................................................................................................................ 28

6.

Error Messages

........................................................................................................................................ 29

7.

Service and Maintenance

........................................................................................................................ 30