20

21

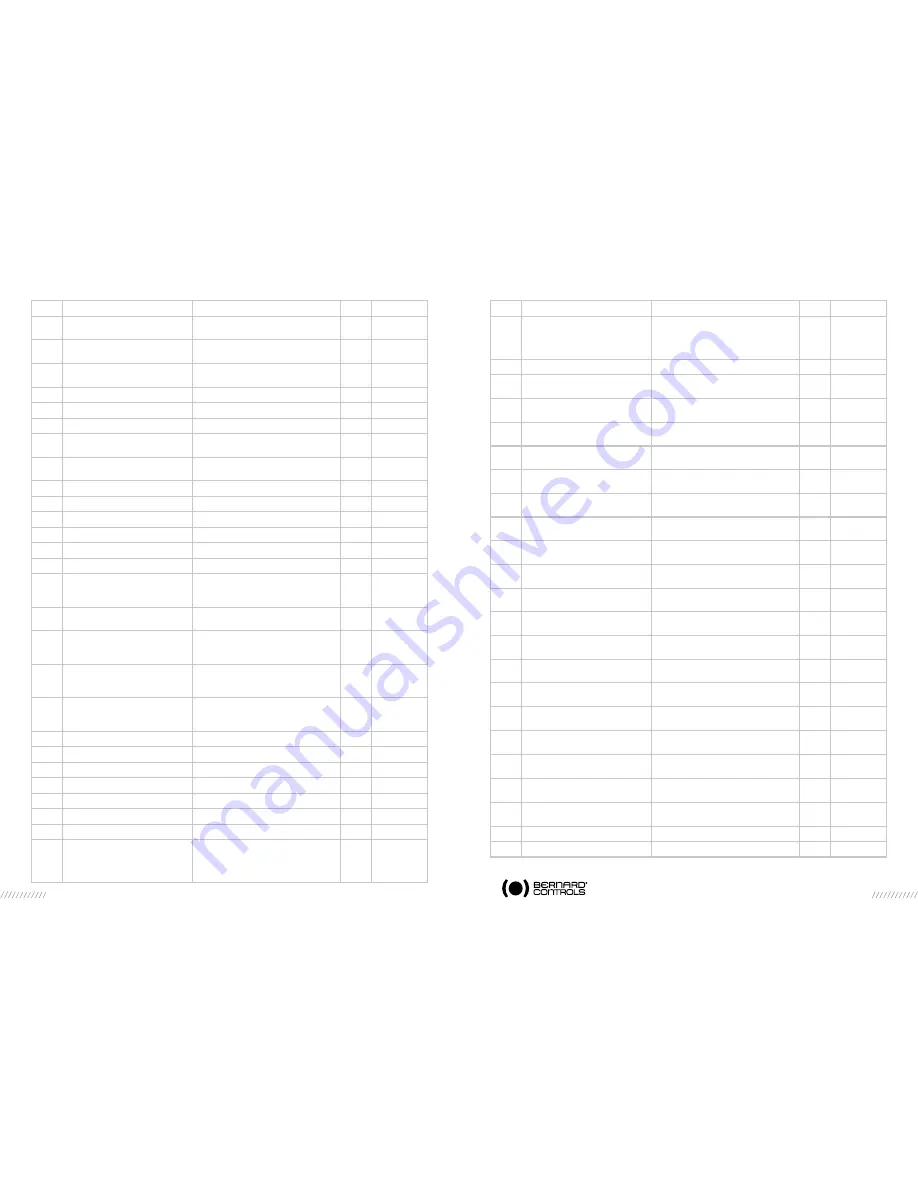

Index

Data

Description

Byte

Read/write

12

End of closing

temporised zone

0 to 100 %

(lower than start value)

1

read / write

13

Start of opening

temporised zone

0 to100 %

1

read / write

14

End of opening

temporised zone

0 to 100 %

(higher than start value)

1

read / write

15

Timer open time expected

in seconds

2

read / write

16

Timer close time expected

in seconds

2

read / write

17

Operating time without timer

in seconds

2

read / write

18

User pass word

ASCII characters

«000» to «999»

3

read / write

19

Valve tag number

ASCII characters

ex: «MOV55VV»

8

read / write

20

Open breakout torque setting

40 to 100%, 101% if no limitation

1

read / write

21

Close tight torque setting

40 to 100%

1

read / write

22

Opening torque setting

40 to 100%

read / write

23

Closing torque setting

40 to 100%

read / write

24

Reset partial running time

0= no, 1= yes

write

25

Reset partial number of starts 0= no, 1= yes

write

26

Operating class

1: On – Off

2: Modulating Classe III

3 : Modulating Classe II

read only

27

Motor supply type

0: 3 phase

1: single phase or DC

read only

28

Closing mode

0: close on position

1: close on torque

3: open and close on torque

read only

29

Stroke unit

1: number of turns

2: degrees

3: mm

read only

30

Nut thread

(If linear system)

In mm (To calculate the stroke

but only during set-up).

Value is zero if no linear system.

read only

31

Locked motor timing

In seconds

1

read only

32

Reverse delay time

(unit 50ms)

ex. 3 = 150ms

1

read only

33

External gear ratio

(format: 1/ )

ex 200 = 1/200

2

read only

34

Stroke measured during set-up For stroke unit see index 29

2

read only

35

Software version

ASCII characters ex:1.03

6

read only

36

Manufacture date

ASCII characters

12

read only

37

Actuator number

ASCII characters

16

read only

38

Opening torque curve

Torque in %.

Data 1 = closed position

Data 2= 1% open

Data 101= 100% open

101

read only

Index

Data

Description

Byte

Read/write

39

Closing torque curve

Torque in %.

Data 1 = closed position

Data 2= 1% open

Data 101= 100% open

101

read only

40

Profibus slave address

1-125

1

read only

41

Indication address 0

Replicate the data

of the cyclic register

1

read only

42

Indication address 1

Replicate the data

of the cyclic register

1

read only

43

Indication address 2

Replicate the data

of the cyclic register

1

read only

44

Indication address 3

Replicate the data

of the cyclic register

1

read only

45

Indication address 4

Replicate the data

of the cyclic register

1

read only

46

Indication address 5

Replicate the data

of the cyclic register

1

read only

47

Indication address 6

Replicate the data

of the cyclic register

1

read only

48

Indication address 7

Replicate the data

of the cyclic register

1

read only

49

Indication address 8

Replicate the data

of the cyclic register

1

read only

50

Indication address 9

Replicate the data

of the cyclic register

1

read only

51

Indication address 10

Replicate the data

of the cyclic register

1

read only

52

Indication address 11

Replicate the data

of the cyclic register

1

read only

53

Indication address 12 -13

Replicate the data

of the cyclic register

2

read only

54

Indication address 14-17

Replicate the data

of the cyclic register

4

read only

55

Indication address 18-21

Replicate the data

of the cyclic register

4

read only

56

Indication address 22-25

Replicate the data

of the cyclic register

4

read only

57

Indication address 26-29

Replicate the data

of the cyclic register

4

read only

58

Indication address 30-31

Replicate the data

of the cyclic register

2

read only

59

Indication address 32

Replicate the data

of the cyclic register

1

read only

60

Partial stroke %

1 to 100%

1

read/write

61

Partial stroke start position

0=close, 1=open

1

read/write