40

(2) Setting Method

This function is working only in absolute position value. The position error can happen

due to the work status in push mode. Push motion command can be executed by 2

methods. One is RS-485 communication(DLL library) method and the other is external

digital signal(PT Start command) method.

①

DLL library method

The following table shows the setting conditions and refer to

‘

CK10_UserManual_Communication Function_MODBUS

’.

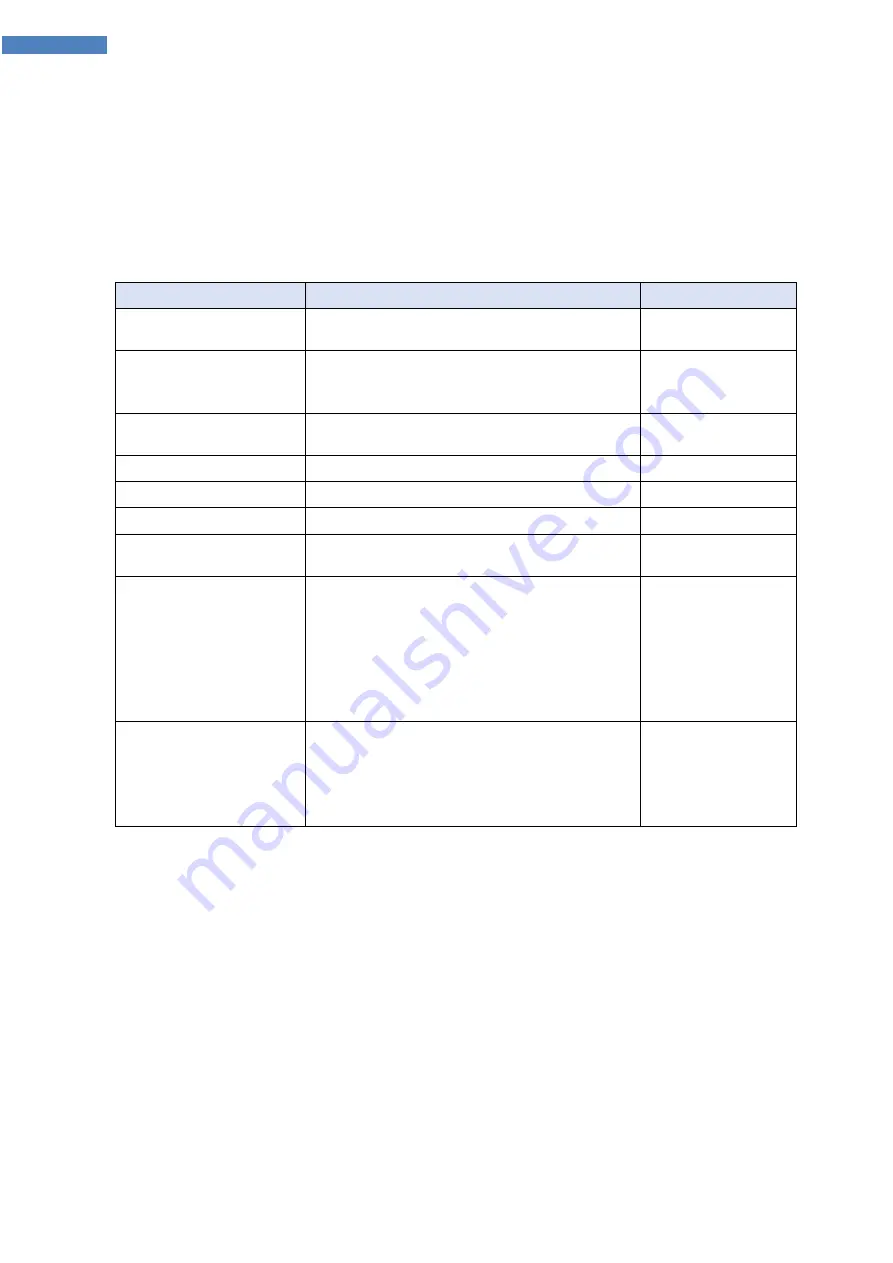

Setting Item

Description

Range *1

Position motion/ Start

speed

Start speed value of position motion

1~35000[pps]

Position motion/

Moving

speed

Moving speed of position motion

1~500000[pps]

Position mode/ Target

Position

Absolute target position of position

command

-2,147,483,648 ~

2,147,483,647

Accel time

Accel time of position motion

1~9,999[ms]

Deceleration time

Decelerate time of position motion

1~9,999[ms]

Push ratio

Motor torque value in push mode

20~90[%]

Push motion/ Moving

speed

Moving speed of Push motion (max

400[rpm])

1~66000[pps]

Push motion/ Target

position

Absolute target position of push command

*Non-stop mode : the value must be set

more than ‘ Position command Target

Position’ value.

*The motor will stop if the position is

exceed this

value even if the work is not detected.

-2,147,483,648 ~

2,147,483,647

Push mode

Set Stop mode(0) or Non-stop

mode(1~10000) after the work detect. In

case of Non-stop mode, the motor move

backward as much as this

value[pulse].

0~10,000

*1 : The unit of [pps] in this item is referenced to 10,000[ppr] encoder.

②

Input signal(PT Start) Method

Firstly the position table data must be entered before the push motioning and

refer to ‘

CK10_UserManual_Position Table

’ .