-13-

6.2.2 OPEN LOOP CONTROL PARAMETERS

6.2.2.1 CMD UNITS

This is a four character label that will be displayed with the

input command and it’s associated parameters. It is entirely

configurable by the operator. When selected for update, the

first of the four characters is highlighted. The

↑

/

↓

selections

are used to scroll through the available characters: A-Z, a-z,

space, -, % and /. Selecting

E

nter will set the displayed character

and continue to the next. When all four characters have been

set, the label is saved. At anytime prior to the final character

being set,

C

ancel may be selected and no change to the label

will be made.

6.2.2.2 CMD MAX

This is the input reading that is to be associated with the

maximum input signal of 20ma or 5V.

6.2.2.3 CMD MIN

This is the input reading that is to be associated with the

minimum input signal of 4ma or 1V.

6.2.2.4 CMD DAMP

Dampening is the amount of time over which the command

input signal is averaged. The setting may range from 0

seconds (no dampening) to 25 seconds. This is used to

smooth out rapid fluctuations of the input signal.

6.2.2.5 CMD LO ALRM

This is the level that signifies a low input command. When

the input command falls below this level, an alarm is

generated.

6.2.2.6 CMD ALRM DB

This parameter determines when the CMD LO ALRM is

cleared. The input command reading must rise above the

alarm level by this amount in order for the system to clear an

existing low command alarm. The parameter may be set

from 0.3% to 25% of the Input command range.

6.2.2.7 CMD LOS ACT

This is the action taken when the input command is lost. It

may be configured as

LOCK – actuator locks in place at its current position

DTZ – actuator drives to the Zero position

DTS – actuator drives to the Span position

DTP – actuator drives to a user selected position

6.2.2.8 CMD LOS POS

This is the position to which the actuator will drive when the

CMD LOST ACT parameter is set to Drive To Position and

the signal is lost.

6.2.2.9 LOC/REM RADIO

This parameter configures whether the RATIO multiplier of

the system is obtained locally when set to LOCAL, or if it is

obtained from the input signal (on input pair number 3)

when set to REMOTE.

SOFTWARE SETUP

Configuration

6.1 Basic Parameters

6.1.1 DEADBAND

This adjustment establishes the servo sensitivity. It is factory

set but may be adjusted, if necessary, in the field. If the

actuator begins to oscillate (rapidly adjusting around a single

point) the sensitivity can be decreased. Increase the

deadband parameter until the oscillation no longer occurs.

Oscillation will reduce the life of the unit.

6.1.2 SPEED

LINEAR SPEED

This is the speed at which the unit moves in a linear direc-

tion. It may be set to either .13 or .25 inches/second.

ROTARY SPEED

This is the selection to set the rotary speed of the actuator.

It is adjustable between TBD. There are no units associated

with this parameter other than those the operator desires to

use. See SPEED UNITS parameter.

6.1.3 SPEED UNITS

This parameter is available only for rotary actuators. It is a

four-character user programmable unit string to associate with

the speed parameter.

6.1.4 ACUATOR TYPE

This parameter configures the unit as linear or rotary.

6.2 Control Setup

6.2.1 CONTROL MODE SELECTION

This selects the control mode that the actuator uses to

determine its output position:

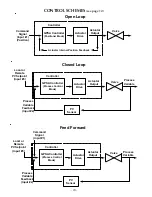

6.2.2 OPEN LOOP:

(See page 19 for diagram)

In this mode the output position is directly proportional to

the input command provided on input terminal pair #1.

6.2.3 CLOSED LOOP:

(See page 19 for diagram)

This strategy is integral based and adjusts the output position

of the actuator based on the difference between a desired

local or remote Set Point (terminal pair #3) and the actual

Process variable signal on terminal pair #2. This adjustment

is added incrementally over a specified integral time. The

amount of the correction is continually calculated/updated.

6.2.4 FEED FORWARD:

(See page 19 for diagram)

This mode combines the control strategies of proportional

and process variable control mentioned above. The output

setting is adjusted in proportion to the input command on

terminal pair #1 and a correction factor is applied which is

derived from the error between the desired local or remote

Set Point (terminal pair #3) and the actual input signal on

input terminal pair #2.