SERIES IP220 INDUSTRIAL I/O PACK

1

2

-BIT HIGH-DENSITY ANALOG OUTPUT MODULE

3. Read the PROM to retrieve the channel's unique gain calibration

error data. For channel 0, read byte CD BASE + 43H. An 8 bit

two's compliment number is read (assume Fl H). This

corresponds to a PROM_Gain_Error of -15 decimal.

4. Calculate the Ideal_Count required to provide an uncorrected

output of the desired value (-2.5 Volts) by using equation (2).

Ideal_Count

= [(4096 / 20) * -2.5] + 2048 = 1536.0

5. Calculate the Corrected_Count required to provide an accurate

output of the desired value (-2.5 Volts) by using equation (4).

Corrected_Count

= [(1 + (-15 / 16384)) * (1536.0 - 2048)] +

(2048 + (32 / 4)) = 1544.47

6. Write to the DAC Channel 0 Register © BASE + OOH with the

desired data (6080H - data is determined by rounding 1544.47

decimal to 1544, then converting to Hex 608 and left justifying

as 6080H).

7. (OPTIONAL) Observe or monitor that the specific DAC channel

(0) reflects the results of the digital data converted to an analog

output voltage at the field connector.

8. Repeat steps 2-7 to adjust the unique calibration characteristic

and update each channel used, or repeat steps 4-7 to update

the value of a single channel.

Error checking should be performed on the calculated count

values to insure that calculated values below 0 or above 4095

decimal are restricted to those end points. Note that the software

calibration cannot generate outputs near the endpoints of the range

which are clipped off due to the uncalibrated hardware (i.e. the

DAC).

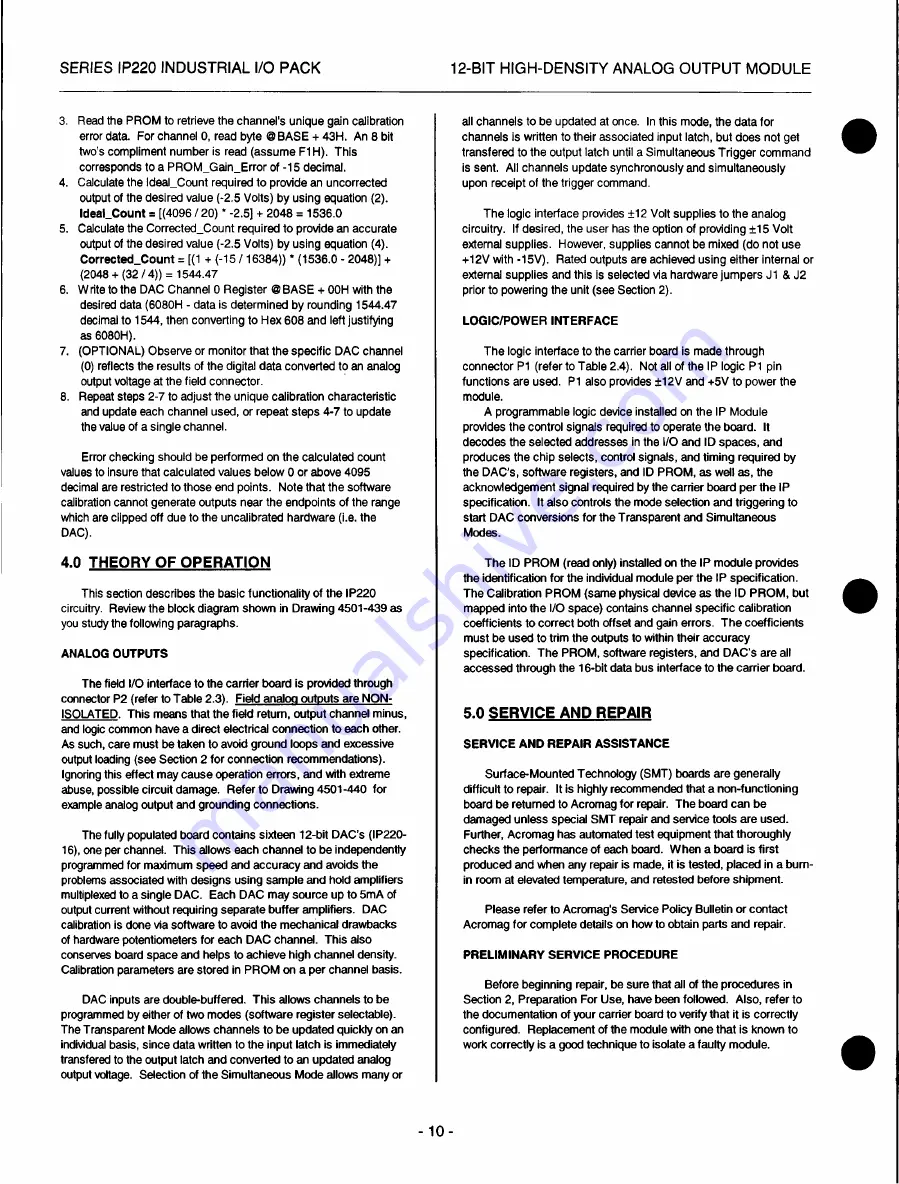

4.0 THEORY OF OPERATION

This section describes the basic functionality of the IP220

circuitry. Review the block diagram shown in Drawing 4501-439 as

you study the following paragraphs.

ANALOG OUTPUTS

The field I/O interface to the carrier board is provided through

connector P2 (refer to Table 2.3). Field analog outputs are

NON

-

ISOLATED. This means that the field return, output channel minus,

and logic common have a direct electrical connection to each other.

As such, care must be taken to avoid ground loops and excessive

output loading (see Section 2 for connection recommendations).

Ignoring this effect may cause operation errors, and with extreme

abuse, possible circuit damage. Refer to Drawing 4501-440 for

example analog output and grounding connections.

The fully populated board contains sixteen 12-bit DAC's (IP220-

16), one per channel. This allows each channel to be independently

programmed for maximum speed and accuracy and avoids the

problems associated with designs using sample and hold amplifiers

multiplexed to a single DAC. Each DAC may source up to 5mA of

output current without requiring separate buffer amplifiers. DAC

calibration is done via software to avoid the mechanical drawbacks

of hardware potentiometers for each DAC channel. This also

conserves board space and helps to achieve high channel density.

Calibration parameters are stored in PROM on a per channel basis.

DAC inputs are double-buffered. This allows channels to be

programmed by either of two modes (software register selectable).

The Transparent Mode allows channels to be updated quickly on an

individual basis, since data written to the input latch is immediately

transfered to the output latch and converted to an updated analog

output voltage. Selection of the Simultaneous Mode allows many or

all channels to be updated at once. In this mode, the data for

channels is written to their associated input latch, but does not get

transfered to the output latch until a Simultaneous Trigger command

is sent. All channels update synchronously and simultaneously

upon receipt of the trigger command.

The logic interface provides ±12 Volt supplies to the analog

circuitry. If desired, the user has the option of providing ±15 Volt

external supplies. However, supplies cannot be mixed (do not use

+12V with -15V). Rated outputs are achieved using either internal or

external supplies and this is selected via hardware jumpers J1 & J2

prior to powering the unit (see Section 2).

LOGIC/POWER INTERFACE

The logic interface to the carrier board is made through

connector P1 (refer to Table 2.4). Not all of the IP logic P1 pin

functions are used. P1 also provides ±12V and +5V to power the

module.

A programmable logic device installed on the IP Module

provides the control signals required to operate the board. It

decodes the selected addresses in the I/O and ID spaces, and

produces the chip selects, control signals, and timing required by

the DAC's, software registers, and ID

PROM,

as well as, the

acknowledgement signal required by the carrier board per the IP

specification. It also controls the mode selection and triggering to

start DAC conversions for the Transparent and Simultaneous

Modes.

The ID

PROM

(read only) installed on the IP module provides

the identification for the individual module per the IP specification.

The Calibration

PROM

(same physical device as the ID

PROM,

but

mapped into the I/O space) contains channel specific calibration

coefficients to correct both offset and gain errors. The coefficients

must be used to trim the outputs to within their accuracy

specification. The PROM, software registers, and DAC's are all

accessed through the 16-bit data bus interface to the carrier board.

5.0 SERVICE AND REPAIR

SERVICE AND REPAIR ASSISTANCE

Surface-Mounted Technology (SMT) boards are generally

difficult to repair. It is highly recommended that a non-functioning

board be returned to Acromag for repair. The board can be

damaged unless special SMT repair and service tools are used.

Further, Acromag has automated test equipment that thoroughly

checks the performance of each board. When a board is first

produced and when any repair is made, it is tested, placed in a bum-

in room at elevated temperature, and

retested

before shipment.

Please refer to Acromag's Service Policy Bulletin or contact

Acromag for complete details on how to obtain parts and repair.

PRELIMINARY SERVICE PROCEDURE

Before beginning repair, be sure that all of the procedures in

Section 2, Preparation For Use, have been followed. Also, refer to

the documentation of your carrier board to verify that it is correctly

configured. Replacement of the module with one that is known to

work correctly is a good technique to isolate a faulty module.

- 1 0 -