DEFROST CONTROL

The instrument can be used to select dif-

ferent types of defrosting with the para-

meter

dty, defrost type

.

(defrost execution mode).

The dty parameter can have these values:

0 = Electrical or Off Cycle defrost

(Compressor OFF during Defrost);

1 = Reverse cycle defrost

(hot gas - Compressor On during Defrost);

2 = ’Free’ : Independent defrost

(compressor cycles ON/OFF according to

temperature during defrost)

Configuration of 3

rd

probe as 2nd evap-

orator probe

The 3

a

probe can be used to control the

defrosting of a second evaporator by con-

figuring a relay output as a 2nd evaporator

defrost relay (see par. H21…H26).

To implement this function:

a) configure the 3

rd

probe in 2nd evapora-

tor defrost control mode (par. H43=2EP).

b) configure a relay output as 2nd evapo-

rator defrost relay (configuration parame-

ters H21…H26).

c) define the defrost mode by setting

parameter H45.

Start of defrosting

If two evaporators are used, defrosting

starts in three different ways that are

determined by parameter H45.

• H45=0: Defrosting is enabled by con-

trolling the temperature of the 1st evapo-

rator so it is lower than parameter dSt,

•H45=1: Defrosting is enabled by control-

ling so that at least one of the two probes

is below its end of defrosting temperature

(dSt for the 1st evaporator and dS2 for

the 2nd evaporator)

• H45=2: Defrosting is enabled by control-

ling so that both the probes are below

their respective end of defrosting set

points (dSt for the 1st evaporator and dS2

for the 2nd evaporator)

The probe error condition is considered

the defrost calling probe.

When defrosting is terminated by a probe

or is timed out (see par. dEt), dripping fol-

lows (see par. dt).

End of defrosting

If two evaporators are used, defrosting

ends when both the probes have reached

or exceeded their respective end of

defrosting set points (dSt for the 1st evap-

orator and dS2 for the 2nd evaporator)

If one or both the probes are faulty,

defrosting is ended by a time-out.

NOTE:

• If there are no conditions for defrosting,

the request is ignored.

Defrosting of a single evaporator ends

when the value read by the respective

probe is equal to or higher than the end

of defrosting temperature or a time-out

occurs. Dripping starts when both defrosts

have been completed.

• If one or both the probes are faulty,

defrosting in the corresponding evaporator

is ended by a time-out.

The start of defrosting is permitted when

the corresponding temperature is lower

than the corresponding set point (dSt or

dS2).

• If probe 3 is not configured as a probe

on the second evaporator (H43

≠

2),

defrosting on the second evaporator

occurs if a digital output is configured to

control defrosting on the second evapora-

tor (see par. H21..H25). If this is the case,

defrosting is confirmed (as if ST3<dS2)

and ends with a time-out. The fan con-

troller remains unchanged.

GENERAL PRESSURE SWITCH INPUT

CONTROLLER

This controller performs diagnostics on an

associated digital input using a configura-

tion table. It is activated by setting para-

meters H11 and H12 = 9.

If the pressure switch input trips, the com-

pressor loads are immediately deactivated,

the alarm LED lights up to signal tripping

and the label nPA in the alarm folder

appears on the display.

Controlling is performed using 2 parame-

ters PEn and PEI:

nPA is a subfolder of AL (Alarms), and

keeps a record of each time the pressure

switch is activated if the value indicated by

PEn is reached in a period of time that is

less than or equal to PEI, the label nPA is

replaced by PA (pressure alarm).

The alarm conditions only occurs when the

maximum number of alarms is reached

before the time indicated by parameter

PEI expires. As soon as the first alarm

occurs, the time PEI is calculated.

If the number of times the pressure switch

is activated exceeds the number estab-

lished PEn in the period PEI:

- compressor outputs, fans and defrosting

are deactivated

- the label PA is displayed in the subfolder

nPA

- the alarm LEDs and alarm relay if config-

ured are switched on.

NOTE:

Once the device is in alarm mode,

it must be switched off and on again or

reset by activating the rAP parameter in

the functions menu. The nPA folders can

be reset using the rPA function in the Fnc

folder.

NOTE:

If parameter PEn is set to 0 the

function is excluded and the alarms and

counts are disabled.

CONDENSER FAN CONTROLLER

This controller is associated with probe

Pb3 and features:

- operating set point

- operating differential

- exclusion of fans in defrosting mode

- start-up delay after end of defrosting If a

digital output is set as condenser fans

(H21...H24=10) the output will behave as

shown below:

If probe Pb3 is not present and alarm E3 is

active, the controller will always be on

during the defrost cycle.

Probe 3 can be excluded and the failed

connection with the instrument will not

trigger an error message.

NOTE:

During dripping time the output is

OFF.

NOTE:

If a digital output is programmed

as condenser fans (H21...H25 =10) parame-

ter SA3 is always an absolute value irre-

spective of the value of parameter Att.

DIAGNOSTICS

The alarm condition is always signalled by

a buzzer (if present) and the alarm icon

LED. The alarms from the faulty thermo-

stat control probe (probe 1), the faulty

evaporator probe (probe 2), and the faulty

display probe (probe 3) appear directly on

the instrument display as E1, E2, and E3

respectively.

An error condition in probe 1 (thermostat

control) causes the following:

• E1 code appears on display

• compressor is activated as indicated by

“Ont” and “Oft” parameters if these are

programmed for duty cycle or:

The error condition for probe 2 (evapora-

tor) causes the following:

• E2 code appears on display

• end of defrost due to time-out.

The error condition for probe 3 (display)

causes the following:

• E3 code appears on display Other alarms

do not appear on the instrument display

ID 985/S/E/CK - ID985/E LX

4/14

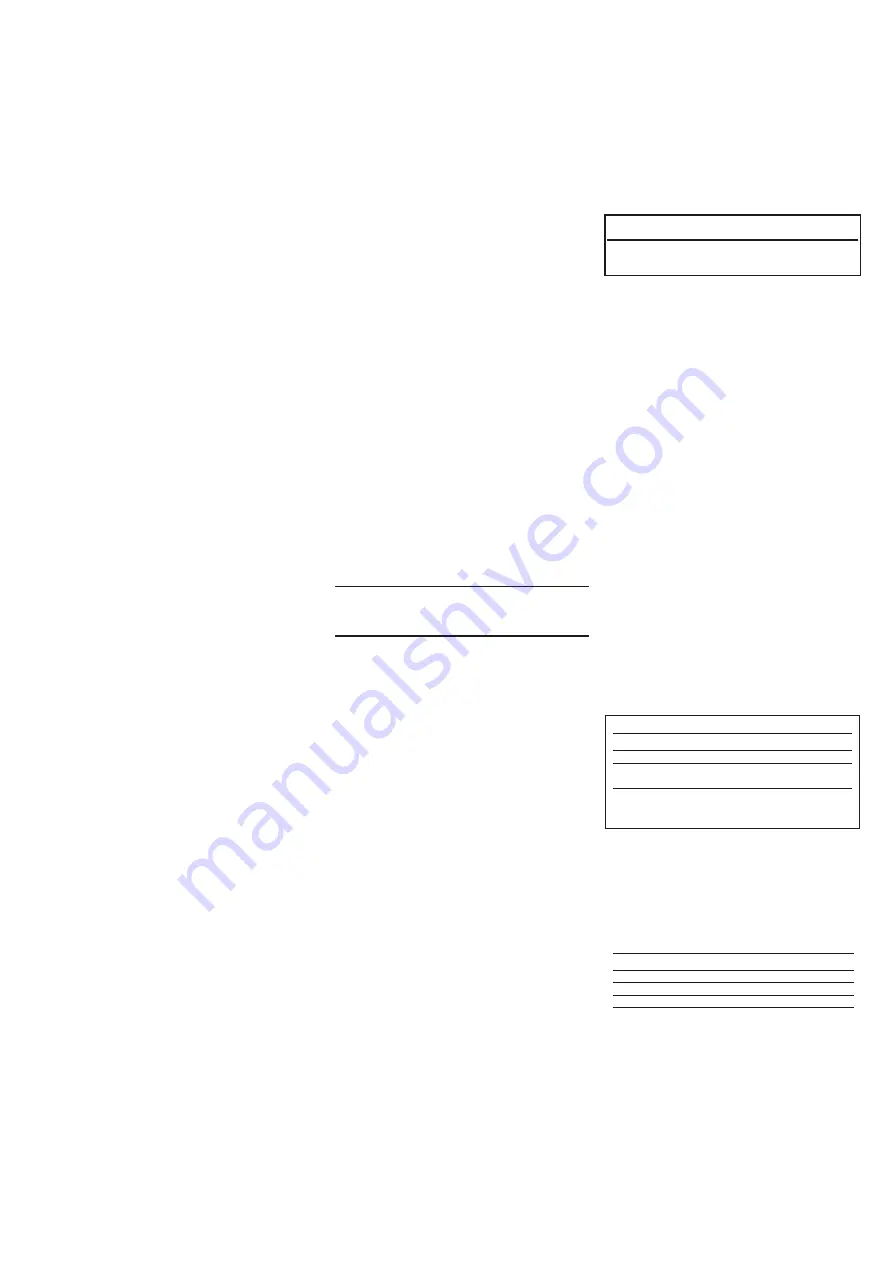

Par.

Description

PEn

number of errors allowed per maximum/

minimum pressure switch input switch

input (number)

PEI

Minimum/maximum pressure switch error

count time (minutes)

Output Value

Pb3 Value

ON

≥

SCF OFF

≤

SCF - dCF

DISPLAY

E1

E2

E3

If simultaneous, they will be showed on the display

alternately every 2 seconds

FAULT

Faulty probe 1 (thermostat control)

Faulty probe 2 (1st evaporator)

Faulty probe 3 (display or 2nd evap-

orator)

Table of faulty probes

Ont

0

0

>0

>0

Oft

0

>0

0

>0

Compressor output

OFF

OFF

ON

dc