8 Programming: Cycles

186

CIRCULAR PATTERN (Cycle 220)

1

At rapid traverse, the TNC moves the tool from its current

position to the starting point for the first machining operation.

The tool is positioned in the following sequence:

■

Move to 2nd set-up clearance (tool axis)

■

Approach starting point in the working plane

■

Move to set-up clearance above the workpiece surface

(tool axis)

2

From this position, the TNC executes the last defined fixed cycle.

3

The tool then approaches the starting point for the next

machining operation on a straight line at set-up clearance (or 2nd

set-up clearance).

4

This process (1 to 3) is repeated until all machining operations

have been executed.

Before programming, note the following:

Cycle 220 is DEF active, which means that Cycle 220

automatically calls the last defined fixed cycle.

If you combine Cycle 220 with one of the fixed cycles

200 to 204 and 212 to 215, the set-up clearance,

workpiece surface and 2nd set-up clearance that you

defined in Cycle 220 will be effective for the selected

fixed cycle!

ú

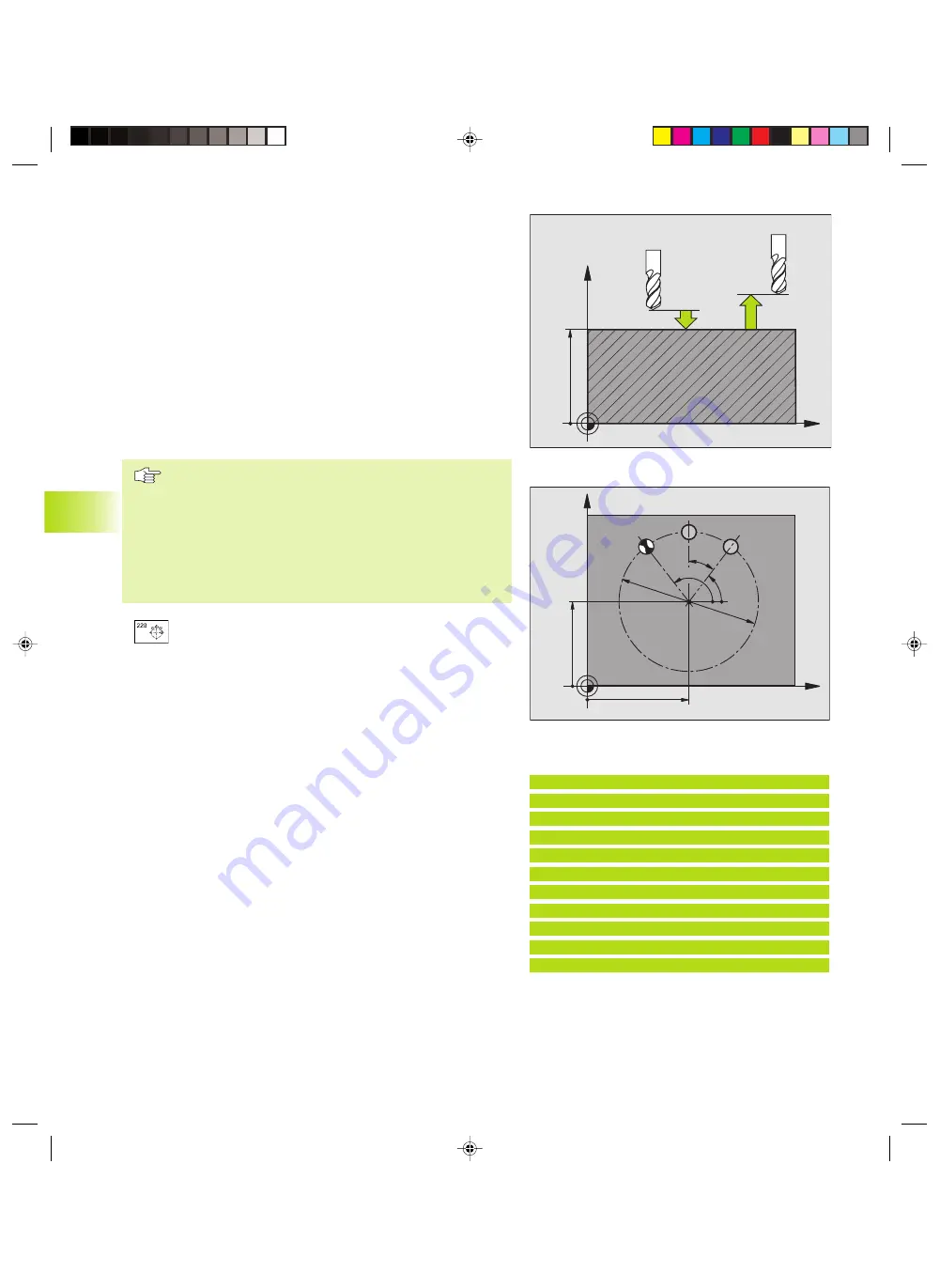

Center in 1st axis Q216 (absolute value): Center of the

pitch circle in the main axis of the working plane

ú

Center in 2nd axis Q217 (absolute value): Center of the

pitch circle in the secondary axis of the working plane

ú

Pitch circle diameter Q244: Diameter of the pitch circle

ú

Starting angle Q245 (absolute value): Angle between

the main axis of the working plane and the starting

point for the first machining operation on the pitch

circle

ú

Stopping angle Q246 (absolute value): Angle between

the main axis of the working plane and the starting

point for the last machining operation on the pitch

circle (does not apply to complete circles). Do not

enter the same value for the stopping angle and

starting angle. If you enter the stopping angle greater

than the starting angle, machining will be carried out

counterclockwise; otherwise, machining will be

clockwise.

ú

ANGLE STEP Q247 (incremental): Angle between two

machining operations on a pitch circle. If you enter an

ANGLE STEP of 0, the TNC will calculate the ANGLE

STEP from the STARTING and STOPPING

ANGLES and the number of pattern repetitions. If you

enter a value other than 0, the TNC will not take the

STOPPING ANGLE into account. The sign for the

ANGLE STEP determines the working direction (- =

clockwise).

8.4 Cy

cles f

or Mac

hining P

oint P

a

tt

er

ns

X

Z

Q200

Q203

Q204

X

Y

Q217

Q216

Q247

Q245

Q244

Q246

N = Q241

Example NC blocks:

53 CYCL DEF 220 POLAR PATTERN

Q216=+50

;CENTER IN 1ST AXIS

Q217=+50

;CENTER IN 2ND AXIS

Q244=80

;PITCH CIRCLE DIAMETER

Q245=+0

;STARTING ANGLE

Q246=+360

;STOPPING ANGLE

Q247=+0

;STEPPING ANGLE

Q241=8

;NR OF REPETITIONS

Q200=2

;SET-UP CLEARANCE

Q203=+0

;SURFACE COORDINATE

Q204=50

;2. SET-UP CLEARANCE

kkap8.pm6

30.06.2006, 07:03

186

www.EngineeringBooksPdf.com

Summary of Contents for TNC 426 B

Page 3: ...BAUSKLA PM6 30 06 2006 07 03 2 www EngineeringBooksPdf com ...

Page 4: ...BAUSKLA PM6 30 06 2006 07 03 3 www EngineeringBooksPdf com ...

Page 6: ...CINHALT PM6 30 06 2006 07 03 2 www EngineeringBooksPdf com ...

Page 16: ...CINHALT PM6 30 06 2006 07 03 12 www EngineeringBooksPdf com ...

Page 17: ...Introduction 1 Dkap1 pm6 30 06 2006 07 03 1 www EngineeringBooksPdf com ...

Page 29: ...Manual Operation and Setup 2 Dkap2_3 pm6 30 06 2006 07 03 13 www EngineeringBooksPdf com ...

Page 83: ...Programming Tools 5 Fkap5 pm6 30 06 2006 07 03 67 www EngineeringBooksPdf com ...

Page 106: ...Fkap5 pm6 30 06 2006 07 03 90 www EngineeringBooksPdf com ...

Page 107: ...Programming Programming Contours 6 Gkap6 pm6 30 06 2006 07 04 91 www EngineeringBooksPdf com ...

Page 165: ...Hkap7 pm6 30 06 2006 07 03 150 www EngineeringBooksPdf com ...

Page 166: ...Programming Cycles 8 kkap8 pm6 30 06 2006 07 03 151 www EngineeringBooksPdf com ...

Page 253: ...kkap8 pm6 30 06 2006 07 04 238 www EngineeringBooksPdf com ...

Page 265: ...LKAP9 PM6 30 06 2006 07 04 250 www EngineeringBooksPdf com ...

Page 266: ...Programming Q Parameters 10 MKAP10 PM6 30 06 2006 07 04 251 www EngineeringBooksPdf com ...

Page 297: ...MKAP10 PM6 30 06 2006 07 04 282 www EngineeringBooksPdf com ...

Page 298: ...Test Run and Program Run 11 NKAP11 PM6 30 06 2006 07 04 283 www EngineeringBooksPdf com ...

Page 312: ...MOD Functions 12 Okap12 pm6 30 06 2006 07 04 297 www EngineeringBooksPdf com ...

Page 332: ...Tables and Overviews 13 Pkap13 pm6 30 06 2006 07 04 317 www EngineeringBooksPdf com ...