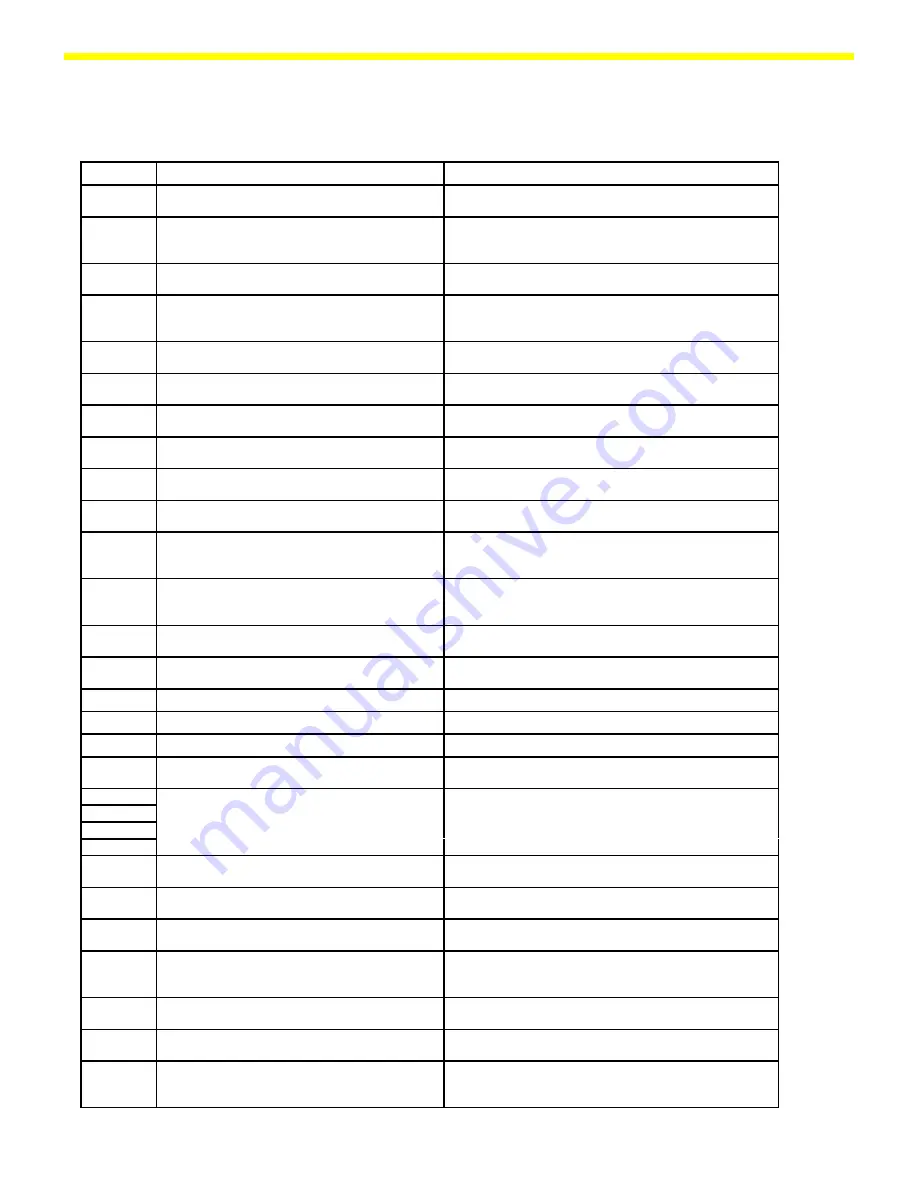

22

Error Codes

Error Code

Explanation

Solution

Err 01

Display overflow, i.e., the value to be output cannot

be displayed

Reset the scale operating menu with code “9-1"

Err 02

Zero point error when starting adjustment function

(scale not tared or load not removed); no stability;

zero point is not within tolerance limits

Unload scale; tare scale; adjust using PSION server; adjust

zero point offset value

Err 03

Zero point error when adjustment function ended

(drift is too strong)

Observe warmup time and restart adjustment function

Err 10

Tare 1 blocked with data in Tare 2

The tare functions are mutually exclusive; once the data in

the tare 2 memory is deleted the tare 1 memory will be

accessible

Err 11

Invalid data;, cannot be stored in the tare memory

Displayed value was negative, for example; check load on

scale

Err 12

Value in tare memory exceeds weighing range

Check load on scale; delete tare data

Err 20

W key was pressed before an application was

initialized

Select an application in the operating menu

Err 22

Reference value not permissible in the counting

application

Reference weight too low or no load on scale

Err 23

Reference value not permissible in the

checkweighing application

No load on scale, or displayed value is negative

Err 30

Print key pressed while BPI mode active

Use the PSION server to switch scale to SBI mode (RS-232

mode).

Err 50

Temperature compensation (TC) converter error;

value measured by the TC switch exceeds the

tolerance range.

TC-sensor or main PCB defective (replace)

Err 53

Temperature compensation (TC) converter not

functioning (no value passed to the scale processor

from the TC switch)

TC-sensor or main PCB defective (replace)

Err 54

Level control in A/D converter under the minimum

limit

Scale underloaded; no weighing pan on the scale;

mechanical defect; main PCB defective (replace)

Err 55

Level control in A/D converter under the maximum

limit

Scale overloaded; mechanical defect; main PCB defective

(replace)

Err 62

key not permitted

Err 63

key not permitted

Err 64

Input via number pad not permitted

Err 70

Faulty input via number pad

Input value too high or too low; data input in the wrong

order

Err 101

Short circuit in the keypad overlay

More than one key pressed when switching on the scale;

keypad defective (replace)

Err 102

Err 103

Err 104

Err 110

Defective KDC-AOC interface

Faulty connection betw. display unit and main PCB;

defective display unit; defective main PCB

Err 220

ROM checksum test (faulty data in the ROM range

of the scale processor)

Reprogram or replace the main PCB

Err 230

RAM read/write test (faulty data in the RAM range

of the scale processor)

Reprogram or replace the main PCB

Err 237

EEPROM checksum test – linearity range defective

(scale has not been linearized or the data stored

are faulty)

Linearize the scale

Err 241

EEPROM checksum test – fixed range (faulty data in

the fixed range of the scale processor)

Overwrite the data records (reprogram or replace the main

PCB)

Err 243

EEPROM checksum test – menu range (faulty data in

the menu range of the scale processor)

Reset the menu (code 9—1)

Err 247

EEPROM checksum test – adjustment weight (scale

has not been adjusted or the data stored are faulty)

Adjust the span of the scale, if necessary, reprogram the

main PCB

Summary of Contents for QC34EDE-S

Page 2: ...2...