User Manual

User Manual

79

78

CRC will write 0xFFFF in superior host, and call a program to process

the consecutive 8 bytes in the message as well as the values in the register.

Only 8-bit data of each character is valid to CRC, the others are all invalid,

including start bit, stop bit and parity check bit.

During the operation of CRC, each of 8-bit character is exclusive(XOR)

with register content separately; result will be inclined to the least significant

bit(LSB) while the most significant bit will be filled with Zero. LSB will be

extracted from the data for checking; if LSB is one, register will be

exclusive(XOR) with preset value separately; if LSB is zero, calculation will

not be conducted. This instruction of process will repeat for 8 times; when it

comes to the last bit (8th bit), the next 8-bit bytes will be exclusive(XOR) with

register value again. The final value in the register is the CRC value after the

calculations of all the bytes in the message.

When CRC is added into the message, lower byte will be added first,

then the high byte. The simple function of CRC is as follows:

unsigned int crc_chk_value

(

unsigned char *data_value,unsigned char length

)

{

unsigned int crc_value=0xFFFF;

int i;

{

return

(

crc_value

)

;

else

}

while

(

length--

)

{

}

crc_value=

(

crc_value>>1

)

}

}

}

crc_value=

(

crc_value>>1

)

if

(

crc_value&0x0001

)

^0xa001

for

(

i=0;i<8;i++

)

{

{

crc_value^=*dat+;

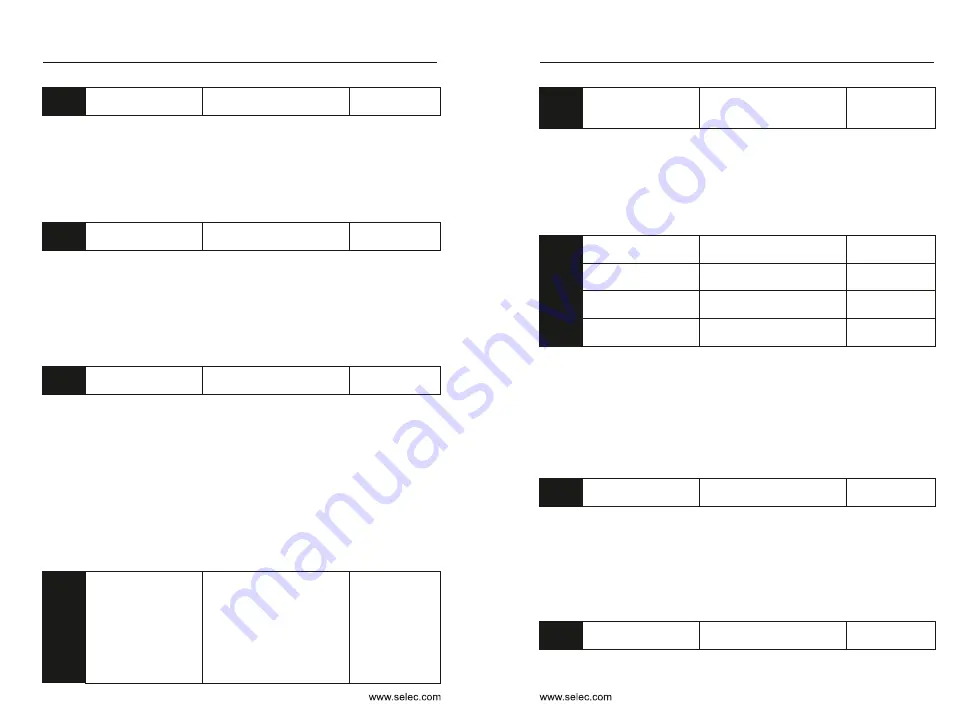

1. Descriptions of the other functions' address

Parameters address monitoring:

Control command

(valid when P0-02 is changed into 3)

Status of Converter

9.5 Read-write rules of parameter address for function code

Register

address

Address

S/N

Data Description

0xDC

Setting freqency

0xDD

221

Output freqency

0xDE

222

Output Current

0xDF

223

Busbar voltage

0xE0

224

Motor speed

0xE1

225

Percentage of current

0xE2

226

IGBT temperature

0xE3

227

Output voltage

0xE4

228

Output power

0xE5

229

Count value

Register

address

Address

S/N

0xE6

230

PI preset value

0xE7

231

PI feedback value

0xE8

232

Run time

0xE9

233

Input interface

0xEA

234

Output interface

0xEB

235

Rated power

0xEC

236

Compensation

Frequency

0xED

237

Compensation voltage

0xEE

238

Phase angle

0xEF

239

Load factors

Register

address

Address

S/N

0xC8

201

1 : FWD run

Data Description

Data Description

2 : FWD jogging

5 : REV run

6 : REV jogging

8 : Stop

16 : Regular stopping

32 : Reset

Register

address

Address

S/N

0xF0

241

0 : Operating

Data Description

1 : FWD running

2 : REV running

6 : Malfunctioning

0xF2

240

0xF3

242

Analog AI2

given value

0xF4

244

Keyboard

potentiometer set

value

245

Analog AI1

given value

Vector control

slip gain

50%

〜

200%

Default

:

100%

P2-06

For speed sensor vector control, this parameter can adjust the output

current of the inverter under the same load.

For speed sensorless vector control, this parameter is increased when the

speed is lower when the motor is loaded, and vice versa.

For speed sensor vector control, this parameter can adjust the output

current of the inverter under the same load.

Time constant of

speed loop filter

0.000s

〜

0.100s

Default

:

0.050s

P2-07

In vector control mode, the output of the speed loop regulator is the torque

current command, which is used to filter the torque command. This parameter

generally does not need to be adjusted. When the speed fluctuates greatly,

the filtering time can be appropriately increased. If the motor oscillates, the

parameter should be appropriately reduced. The speed loop filter time

constant is small, the inverter output torque may fluctuate greatly, but the

speed response is fast.

Vector controlled

over-excitation gain

0

〜

200

Default

:

64

P2-08

During deceleration, the over-excitation control can suppress the rise of

the bus voltage and avoid overvoltage faults. The larger the over-excitation

gain, the stronger the suppression effect.

In the case where the inverter is easy to overvoltage alarm during the

deceleration process, it is necessary to increase the over-excitation gain.

However, the over-excitation gain is too large, which tends to cause an

increase in the output current, which needs to be weighed in the application.

For applications where the inertia is small, there is no voltage rise during

motor deceleration. It is recommended to set the over-excitation gain to 0. For

those with braking resistors, it is also recommended to set the over-excitation

gain to 0.

Torque upper limit

source in speed

control mode

0

:

Function code P2-10

setting

1: AI1 2: AI2 3: AI3

4: Pulse setting

5: Communication setting

6: MIN (AI1, AI2)

7: MAX (AI1, AI2) The full

scale of the 1-7 option

corresponds to P2-10

Default

:

0

Digital setting of

torque upper limit

in speed control mode

0.0%

〜

200.0%

Default

:

150.0%

P2-09

P2-10

In the speed control mode, the maximum value of the inverter output

torque is controlled by the torque upper limit source.

P2-09 is used to select the setting source of the upper torque limit. When

it is set by analog quantity, pulse and communication, the corresponding

setting of 100% corresponds to P2-10, and 100% of P2-10 is the rated torque

of the inverter.

Excitation adjustment

proportional gain

0

〜

60000

Default

:

2000

Excitation regulation

integral gain

0

〜

60000

Default

:

1300

Torque adjustment

proportional gain

0

〜

60000

Default

:

2000

Torque adjustment

integral gain

0

〜

60000

Default

:

1300

P2-13

P2-14

P2-15

P2-16

The vector control current loop PI adjusts the parameter, which is

automatically obtained after the asynchronous machine is fully tuned, and

generally does not need to be modified.

Need to be reminded that the integral regulator of the current loop does

not use the integration time as the dimension, but directly sets the integral

gain. The current loop PI gain setting is too large, which may cause the entire

control loop to oscillate, so when the current oscillation or torque fluctuation

is large, the PI proportional gain or integral gain can be manually reduced.

Maximum output

voltage coefficient

100%~110%

Default

:

105%

P2-20

The maximum output voltage coefficient indicates the boosting capacity

of the maximum output voltage of the inverter. Increasing the F2-20 can

increase the maximum load capacity of the weak field of the motor, but the

increase of the motor current ripple will increase the heat generated by the

motor; otherwise, the maximum band of the weak field of the motor The load

capacity will decrease, but the motor current ripple will decrease, which will

reduce the heat generated by the motor. Generally no adjustment required.

Weak magnetic zone

maximum torque factor

50%~200%

Default

:

100%

P2-21

Chapter 6

Chapter 6