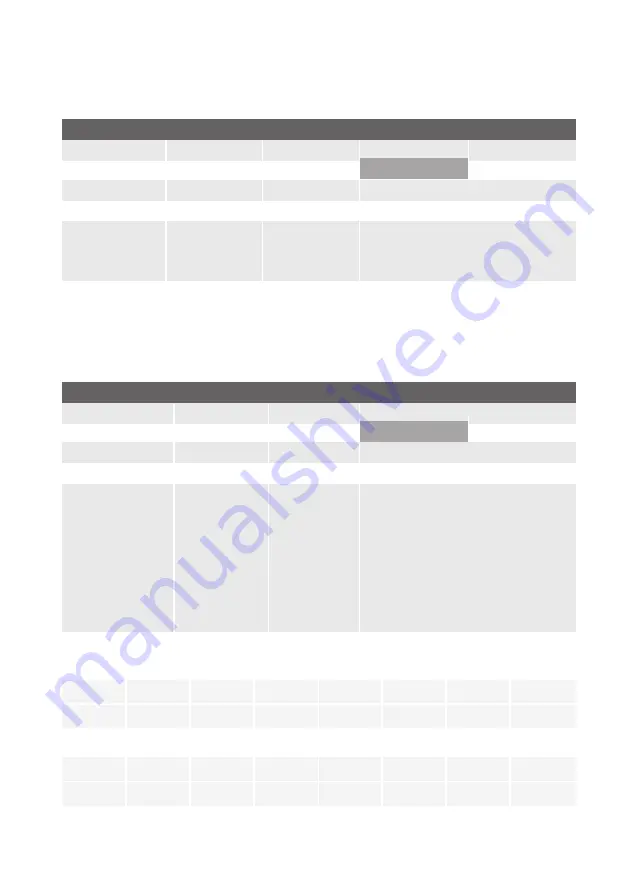

The mode setting frame is use to set the control interface of HUNTER 2.0. The detailed content of the protocol is as follows.

9

Sending node

Decision-making control unit

Date length

Position

byte [0]

Receiving node

Chassis node

0×01

Function

Control mode

ID

0x421

Date type

unsigned int8

Description

0×00 Standby mode

0×01 CAN command mode

Power-on enters standby mode default

Command Name

Control Mode Setting Command

Cycle (ms)

None

Receive-timeout (ms)

None

Sending node

Decision-making control unit

Date length

Position

byte [0]

Receiving node

Chassis node

0×01

Function

Errors clearing command

ID

0x441

Date type

unsigned int8

Description

0×00 Clear all not serious failure

0×01 Clear steering motor drive communication failure

0×02 Clear rear right motor drive communication failure

0×03 Clear rear left motor drive communication failure

0×05 Clear battery under-voltage failure

0×06 Clear steering encoder communication failure

0×07 Clear remote control signal loss failure

Command Name

Status Setting Command

Cycle (ms)

None

Receive-timeout (ms)

None

[Note] Example data: The following data is only used for testing

1.The chassis moves forward at 0.15m/s ( It need to unlock parking by command before running)

2.The chassis steering 0.2rad

byte [0] byte [1] byte [2] byte [3] byte [4] byte [5] byte [6] byte [7]

0x00

0x00 0x00

0x00

0x00 0x00

0x00 0xC8

byte [0] byte [1] byte [2] byte [3] byte [4] byte [5] byte [6] byte [7]

0x00

0x96 0x00 0x00

0x00 0x00

0x00 0x00

Description of control mode: In case the HUNTER 2.0 is powered on and the RC transmitter is not connected, the control mode is defaulted

to standby mode. At this time, the chassis only receives control mode command, and does not respond other commands. To use CAN for

control need to switch CAN command mode at first. If the RC transmitter is turned on, the RC transmitter has the highest authority, can

shield the control of command and switch the control mode.

Status setting frame is use to clear the system errors. The detailed content of the protocol is as follows.