Chapter 5 Macro Program

145

I Programming

BCD

#i = BCD

[

#j

]

Unconditional branch

Equals to branch

Not equals to branch

Greater than branch

Smaller than branch

Greater than or equals to

branch

Smaller than or equals to

branch

GOTO #i

IF (#i EQ #j) GOTO #k

IF (#i NE #j) GOTO #k

IF (#i GT #j) GOTO #k

IF (#i LT #j) GOTO #k

IF (#i GE #j) GOTO #k

IF (#i LE #j) GOTO #k

G65 H80 P#i Q#j R#k

G65 H81 P#i Q#j R#k

G65 H82 P#i Q#j R#k

G65 H83 P#i Q#j R#k

G65 H84 P#i Q#j R#k

G65 H85 P#i Q#j R#k

G65 H86 P#i Q#j R#k

Please note that #K is

the skip signal in

macro statement and

P#i is the skip signal in

traditional G65H

format.

User alarm

None

G65 H99 P#i

0

≤

P

≤

100

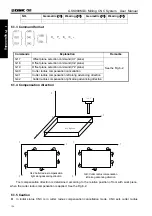

5.3.1 Traditional Format

If traditional G65 H format is used for programming, only limited operations and jump command can be

specified by it. The currently used H operation needs at most 3 operands, so the corresponding operation

can be completed when the needed variables (or constants) are obtained in a block.

z

General format

G65 Hm P#i Q#j R#k

;

m: 01

~

99 means operation command or jump command function

#i: the name of variable that stored the operation result

#j: operand 1; it can be constant.

#k: operand 2; it can be constant.

Meaning: #i = #j

○

#k

└───────

Operational sign, designated by Hm

(Example) G65 Hm P#100 Q#101 R#102……#100 = #101

○

#102

;

G65 Hm R#100 P#101 Q15 ……#101 = 15

○

#100

;

G65 Hm Q#100 R-100 P#102……#102 = #100

○

-100

;

Note 1: G65 H should be commanded prior to operation or jump command.

Note 2: when P code is commanded in G65 block, G65 P means macro program call. H means argument. No

operation or jump command is performed.

Note 3: At most 4 decimal numbers of the constant decimal part can be obtained for rounding. 3 digit numbers can

be displayed in the window.

z

Code function explanation

(1) Variable value assignment, #I

=

#J

G65 H01 P#I Q#J

;

(example) G65 H01 P#101 Q125

;

(#101

=

125)

G65 H01 P#101 Q#110

;

(#101

=

#110)

G65 H01 P#101 Q-#102

;

(#101

=

-#102)

(2) Addition operation #I

=

#J

+

#K

G65 H02 P#I Q#J R#K

;

(example) G65 H02 P#101 Q#102 R15

;

(#101

=

#102

+

15)

G65 H02 P#101 Q#110 R#102

;

(#101

=

#110

+

#102)

(3) Subtraction operation #I

=

#J

-

#K

G65 H03 P#I Q#J R#K

;

(example) G65 H03 P#101 Q#102 R#103

;

(#101

=

#102

-

#103)

(4) Multiplication operation #I

=

#J × #K

Summary of Contents for 980MDc

Page 19: ...GSK980MDc Milling CNC User Manual XVIII ...

Page 20: ...1 I Programming Programming Ⅰ ...

Page 21: ...GSK980MDc Milling CNC System User Manual 2 I Programming ...

Page 139: ...GSK980MDc Milling CNC System User Manual 120 I Programming ...

Page 191: ...GSK980MDc Milling CNC System User Manual 172 I Programming ...

Page 192: ...173 Ⅱ Operation Ⅱ Operation ...

Page 193: ...GSK980MDc Milling CNC System User Manual 174 Ⅱ Operation ...

Page 200: ...Chapter 1 Operation Mode and Display 181 Ⅱ Operation ...

Page 201: ...GSK980MDc Milling CNC System User Manual 182 Ⅱ Operation ...

Page 249: ...GSK980MDc Milling CNC System User Manual 230 Ⅱ Operation ...

Page 253: ...GSK980MDc Milling CNC System User Manual 234 Ⅱ Operation ...

Page 259: ...GSK980MDc Milling CNC System User Manual 240 Ⅱ Operation ...

Page 265: ...GSK980MDc Milling CNC System User Manual 246 Ⅱ Operation ...

Page 293: ...GSK980MDc Milling CNC System User Manual 274 Ⅱ Operation ...

Page 295: ...GSK980MDc Milling CNC System User Manual 276 Ⅱ Operation ...

Page 319: ...GSK980MDc Milling CNC System User Manual 300 Ⅱ Operation ...

Page 320: ...301 Ⅲ Installation Ⅲ Installation ...

Page 321: ...GSK980MDc Milling CNC System User Manual 302 Ⅲ Installation ...

Page 345: ...GSK980MDc Milling CNC System User Manual 326 Ⅲ Installation ...

Page 391: ...GSK980MDc Milling CNC System User Manual 372 Ⅲ Installation ...

Page 392: ...Appendix 373 Appendix Appendix ...

Page 393: ...GSK980MDc Milling CNC System User Manual 374 Appendix ...

Page 394: ...Appendix 375 Appendix Appendix 1 Outline Dimension of GSK980MDc L N ...