66

Laser Seam Tracking System for Welding Automation. RF627Weld Series

RF627Weld [Revision 1.1.1] 03.08.2020

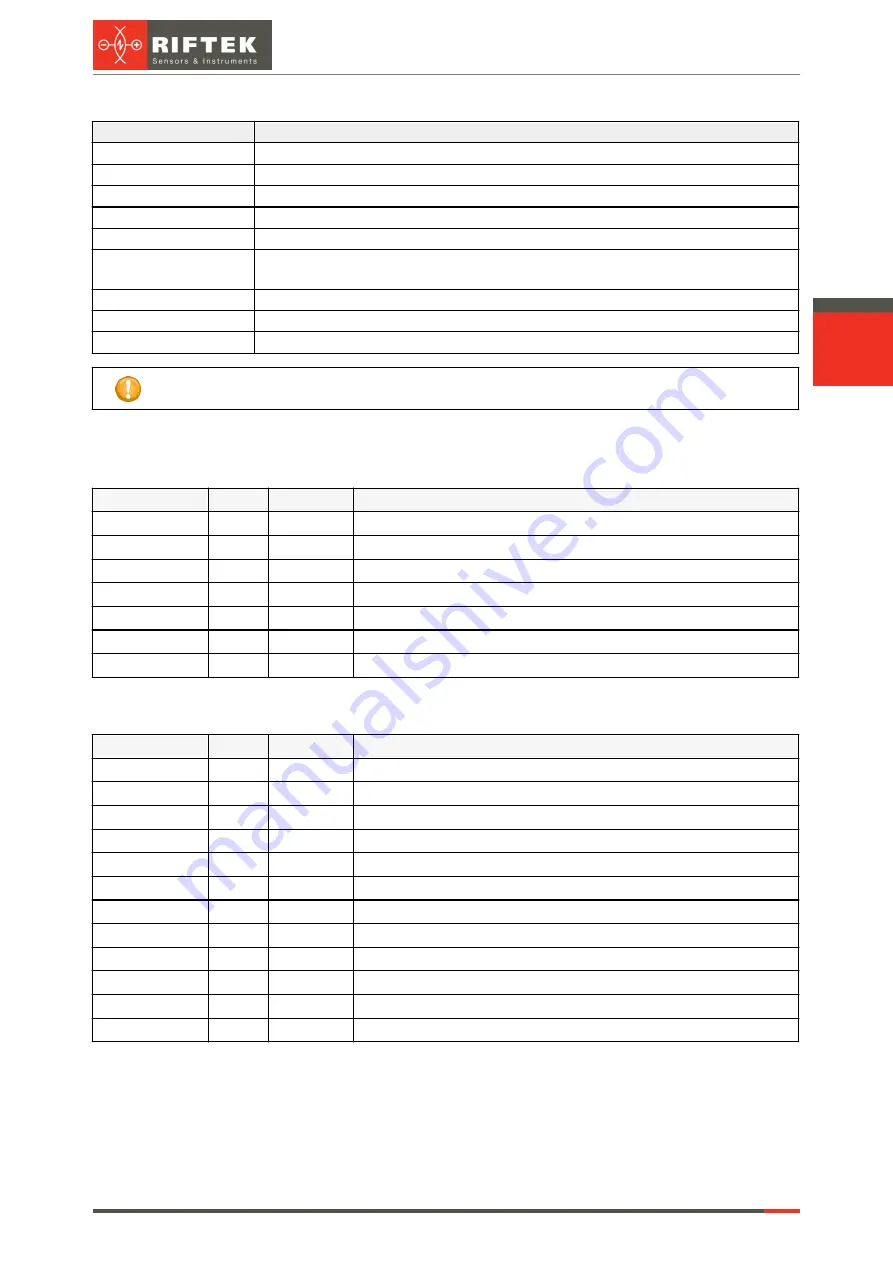

Parameters and buttons:

Parameter

Description

Sensor s/n

Serial number of the scanner.

Sensor target port

UDP port to which the scanner sends profiles (6003 by default).

Protocol

Protocol selection.

Server address

IP address of the robot.

Server port

Robot port (502 by default).

Debug log

Save the debug log: time and type of request from the robot, bytes of commands,

the response time of the program, response bytes, error text.

LOCK SENSOR

Lock the scanner to the protocol settings.

Force template change Forced template change for every received packet.

State

Enable the selected protocol.

When the

State

option is enabled, you cannot change parameters in the

PROTOCOLS

tab.

15.6.4.2. Packets and parameters

Send packet 1 with delay (ms).

Displacement

Length

Field

Description

0

2

TrID1

Transaction ID (set by the client, copied by the server in response)

2

2

ProtoID

Protocol type (0 = Modbus)

4

2

Len1

Quantity of following bytes

6

1

UnitID

Slave address

7

1

Fn1

Function number = 4

8

2

Adr1

Starting register address

10

2

Cnt1

Quantity of registers

Wait for the response, check the high-order bit of the 36th byte: 1 - perform

calculations, 0 - send zeroes in response. Send packet 2 (with results).

Displacement

Length

Field

Description

0

2

TrID1

Transaction ID (set by the client, copied by the server in response)

2

2

ProtoID

Protocol type (0 = Modbus)

4

2

Len1

Quantity of following bytes

6

1

UnitID

Slave address

7

1

Fn2

Function number = 16

8

2

Adr2

Starting register address

10

2

Cnt2

Quantity of registers

12

1

BCnt2

Byte counter

13

2

REG[1]

1st register

15

2

REG[2]

2nd register

...

...

...

...

13+2*(Cnt2-1)

2

REG[Cnt2] The last register

15.6.4.3. Types of calculations (commands) and assignment of registers

Data transmission from the scanner to the robot

:

13-16 bytes - the 1st control point, coordinate X

17-20 bytes - the 1st control point, coordinate Z

21-24 bytes - the 2nd control point, coordinate X