80

Manual – IPOSplus®

6

Modulo function

Position Detection and Positioning

6.7.4

Project planning

6.7.5

Project planning examples

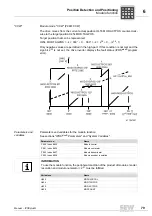

Chain conveyor

Step 1: Defining the output unit

The positions for a chain conveyor are specified in output units. A 360° rotation at the

gear unit output corresponds to the modulo output unit of 360°.

Step 2: Determining the SHELL parameters

SEW employees can read off the number of teeth in the gear unit from the SEW Tech-

nical Manual (DriveNet) or from the electronic nameplate (only for Hiperface

®

).

Definition of drive unit

•

Gear unit and the additional gear make up the output unit 360°

•

Determine the maximum target position in "Number of drive units"

•

Determine 16 bit or resolution (encoder x modulo numerator) for 360°

↓

Determining the SHELL modulo parameters

•

Modulo function P960 (select travel strategy)

•

Modulo numerator P961

•

Modulo denominator P962

•

Modulo encoder resolution P963

Resources for determining the number of teeth in the gear unit:

•

SEW Technical Manual

•

SEW Wingear program to reduce the numerator/denominator factors

↓

Modulo range of representation and maximum output position

•

Condition for the range of representation: Modulo encoder resolution x modulo numerator < 2

31

•

Condition for maximum output position: = 2

31

/ (modulo encoder resolution × modulo numerator)

If this condition is not met, it can lead to positioning errors!

↓

Realization in the IPOS

plus

®

program

•

Specify setpoint position with the H454 ModTagPos variable: MOD.TAGPOS = k × 360° + 0 ... 360° = k

× 2

16

+ 0 ... (2

16

- 1)

•

Read off the actual position in the H455 ModActPos variable: MOD.ACTPOS = ... + 0 ... 360° = ... + 0

... (2

16

- 1)

The system software reads the target position specified in ModActPos and then sets the high word

to 0.

The actual position ModuloActPos always moves between 0° and 360°!

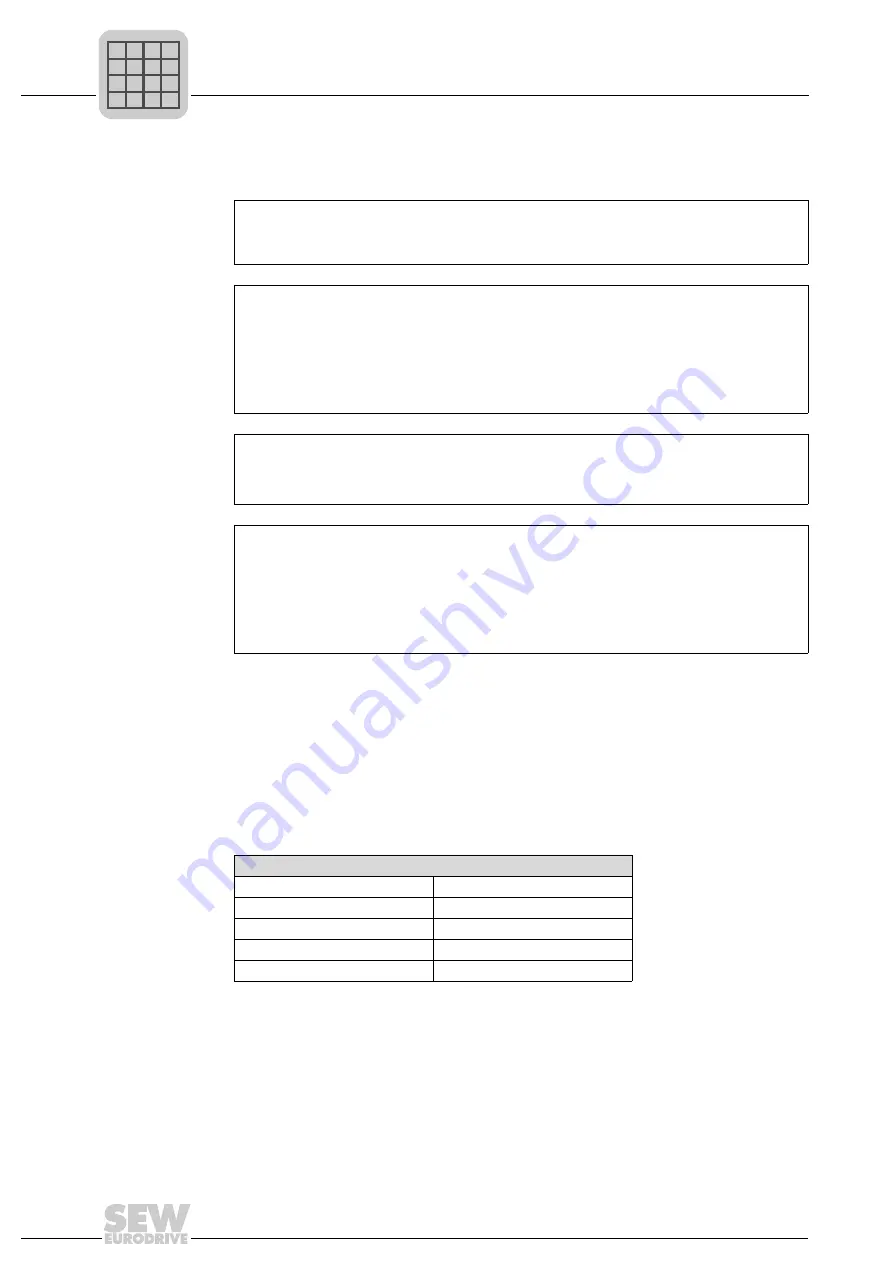

Technical data

Gear unit type

KA47B

Output speed [rpm]

19

Motor speed [rpm]

2000

Gear unit reduction ratio i

104.37

Motor type

DY71S

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n